High-strength glass reinforced plastic sand-doped pipeline

A glass fiber reinforced plastic sand inclusion, high-strength technology, applied in the direction of pipeline protection, pipeline damage/abrasion prevention, pipes, etc., can solve the problems of large resin consumption, mechanical performance limitations, etc., to improve the performance of the adhesive and increase the elongation at break , The effect of reducing the amount of resin used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

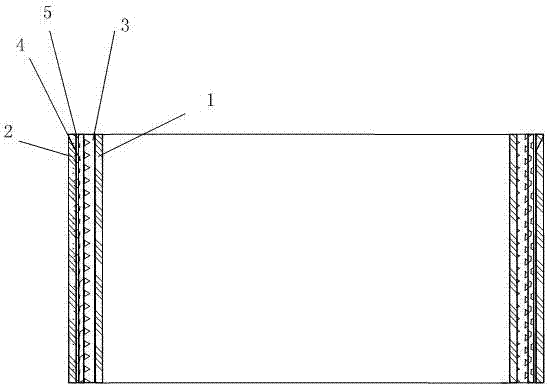

[0011] Such as figure 1 As shown, a high-strength FRP sand-filled pipeline includes a fiber resin mixed layer on the inner wall 1 and the outer wall 2 of the pipeline, and a quartz sand resin mixed layer 3 composed of quartz sand and resin mixture is arranged between the inner wall 1 and the outer wall 2 of the pipeline. , fiber quartz sand mixed layer 4, the resin mixture is made by mixing resin and ground glass fiber, the ratio of the resin to ground glass fiber is 100: (10-15), the fiber quartz sand mixed layer is made of Quartz sand is mixed with glass fibers with a length of (1-5) mm.

[0012] The particle size of the quartz sand in the quartz sand resin mixed layer is 5-20 mesh, and the ratio of the quartz sand to the resin mixture is 90:(10-15).

[0013] The ground glass fiber is E(C)MG-200C type.

Embodiment 2

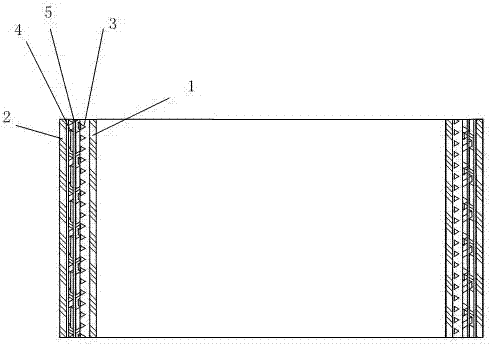

[0015] This embodiment provides a kind of high-strength FRP sand-filled pipeline, such as figure 2 As shown, the difference between embodiment 2 and embodiment 1 is that the sand-filled pipeline is provided with multiple layers of fiber-quartz sand mixed layers separated by layers of abrasive cloth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com