Membrane electrode of direct carbinol full cell fed by liquid state and its prepn. tech

A methanol fuel cell, membrane electrode technology, applied in battery electrodes, battery pack components, circuits, etc., can solve the problems of reduced catalytic activity, catalyst poisoning, high price, etc., to improve fuel utilization, improve structure, and improve performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 1. Membrane preparation and pretreatment. The polyether ether ketone powder is directly sulfonated with sulfuric acid with a concentration of 98%, to obtain a sulfonated polyether ether ketone (SPEEK) solid with a sulfonation degree of 38%, which is dissolved in DMF and placed in an oven on a clean glass plate at 60°C After drying for 8h, a SPEEK film was obtained. The prepared membrane was soaked in 1mol / L sulfuric acid solution for 24 hours, and the prepared proton exchange membrane was immersed in deionized water for use.

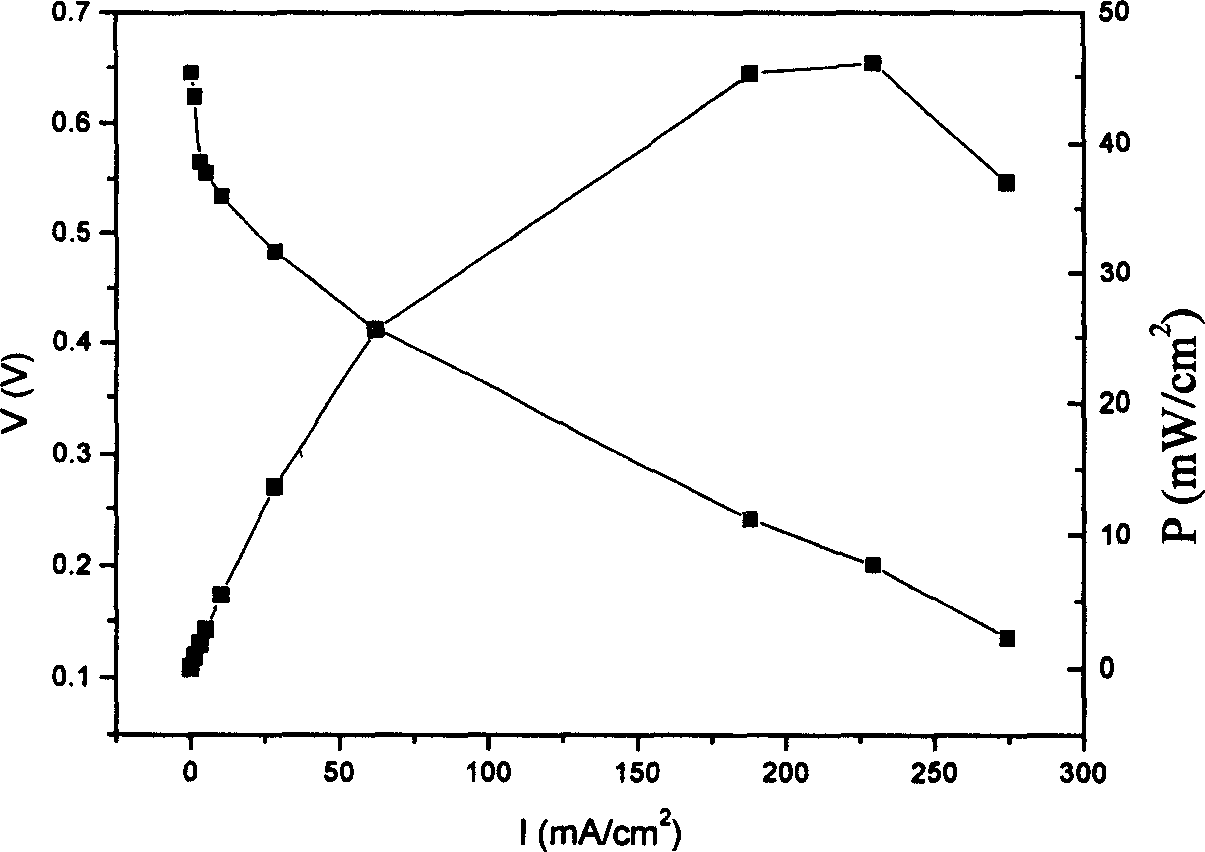

[0017] 2. Use Pt / C and Pt-Ru / C from Johnson Matthey, UK as the anode and cathode catalysts of the direct methanol fuel cell, respectively, and the Pt content is 20%. Take 50mg of anode and cathode catalyst powders respectively, add dispersant and 60mg of 5wt% Nafion emulsion as a binder, ultrasonically disperse into a paste, and then add 3.5mg of PTFE emulsion to the anode catalyst and ultrasonically disperse evenly. Part of the dispersant was v...

Embodiment 2

[0021] 1. Membrane preparation and pretreatment. The polyether ether ketone powder is directly sulfonated with sulfuric acid with a concentration of 98%, to obtain a sulfonated polyether ether ketone (SPEEK) solid with a sulfonation degree of 38%, which is dissolved in DMF and placed in an oven on a clean glass plate at 60°C After drying for 8h, a SPEEK film was obtained. The prepared membrane was soaked in 1mol / L sulfuric acid solution for 24 hours, and the prepared proton exchange membrane was immersed in deionized water for use.

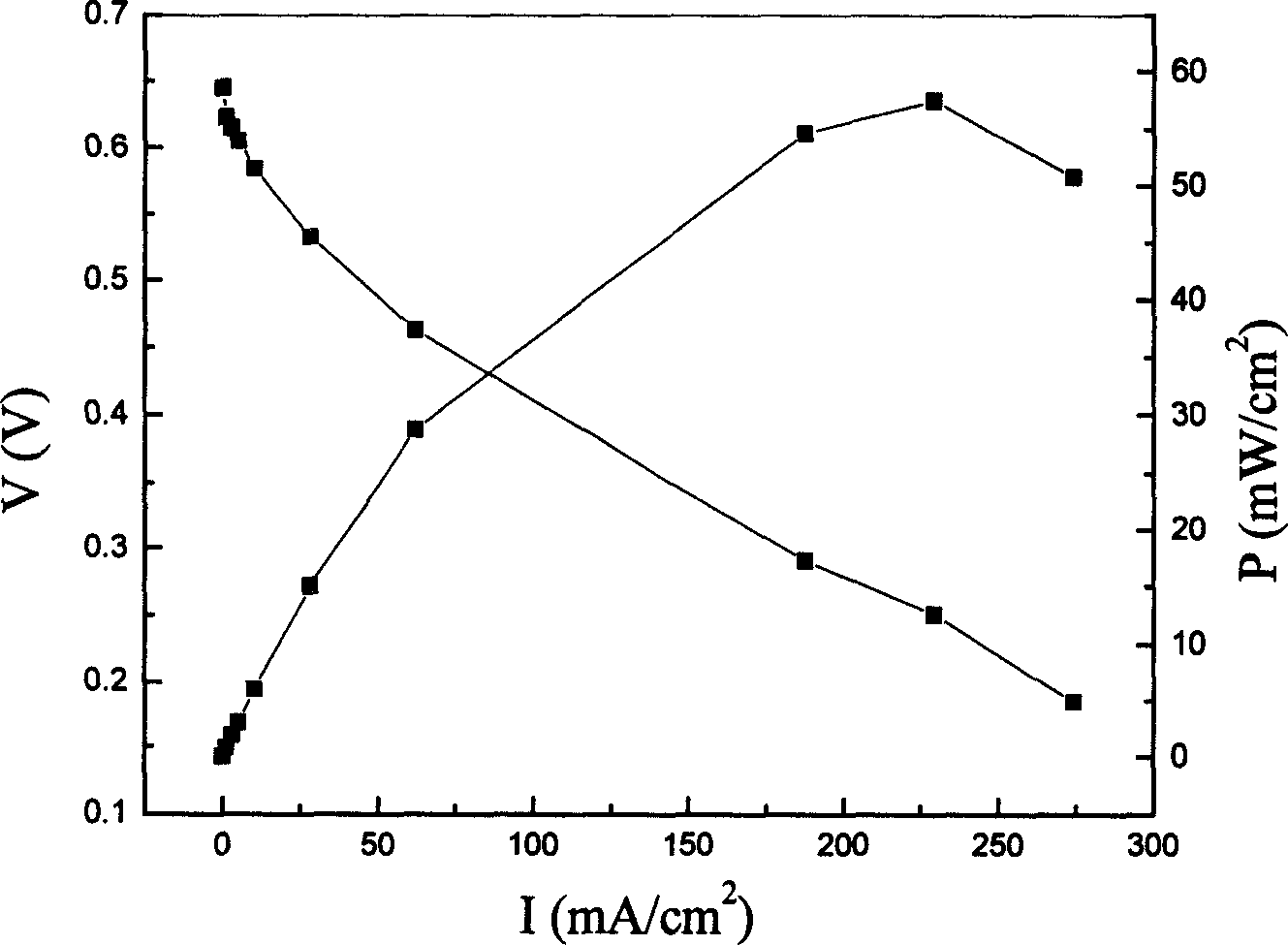

[0022] 2. Use Pt / C and Pt-Ru / C from Johnson Matthey, UK as the anode and cathode catalysts of the direct methanol fuel cell, respectively, and the Pt content is 20%. Take 50mg of anode and cathode catalyst powders, add dispersant and 5wt% Nafion emulsion 60mg as binder, ultrasonically disperse into a paste, then add 3.5mg of PTFE emulsion and 12.5mg of NaHCO to the anode catalyst 3 As a pore forming agent, only 12.5mgNaHCO is added to the cathod...

Embodiment 3

[0026] 1. Membrane preparation and pretreatment. The polyether ether ketone powder is directly sulfonated with sulfuric acid with a concentration of 98%, to obtain a sulfonated polyether ether ketone (SPEEK) solid with a sulfonation degree of 38%, which is dissolved in DMF and placed in an oven on a clean glass plate at 60°C After drying for 8h, a SPEEK film was obtained. The prepared membrane was soaked in 1mol / L sulfuric acid solution for 24 hours, and the prepared proton exchange membrane was immersed in deionized water for use.

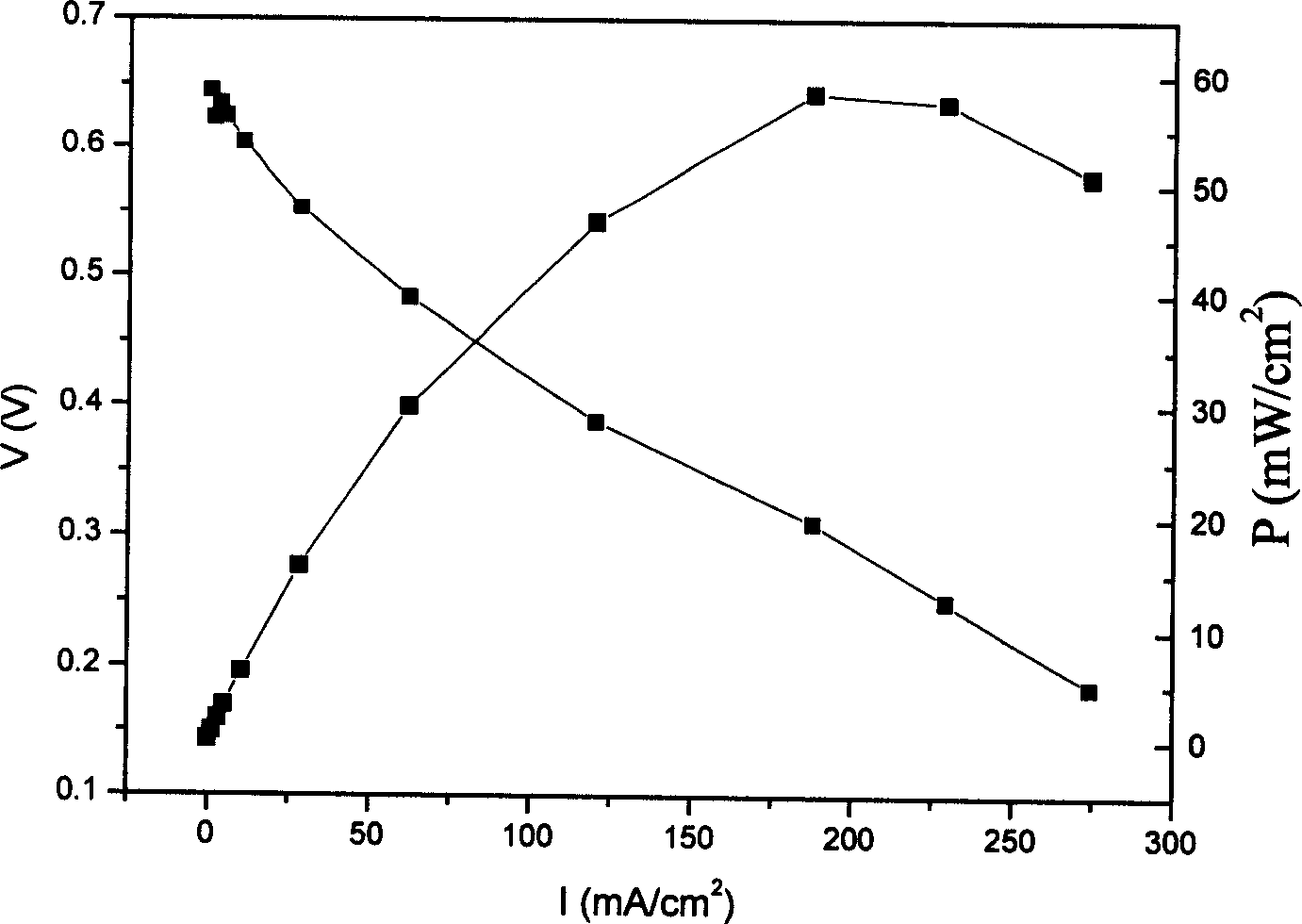

[0027] 2. Use Pt / C and Pt-Ru / C from Johnson Matthey, UK as the anode and cathode catalysts of the direct methanol fuel cell, respectively, and the Pt content is 20%. Take 80mg of anode and cathode catalyst powders, add dispersant and 5wt% Nafion emulsion 96mg as binder, ultrasonically disperse into a paste, then add 5.6mg of PTFE emulsion and 20mgNaHCO to the anode catalyst 3 As a pore forming agent, only 20mgNaHCO is added to the cathode 3 As ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com