Automatic detection meethod and system for smooth surface flaw

An automatic detection and smooth surface technology, applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problems of too small detection caliber, defects cannot be accurately calibrated, and low efficiency, so as to improve work efficiency, The effect of efficient objective detection and digital evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

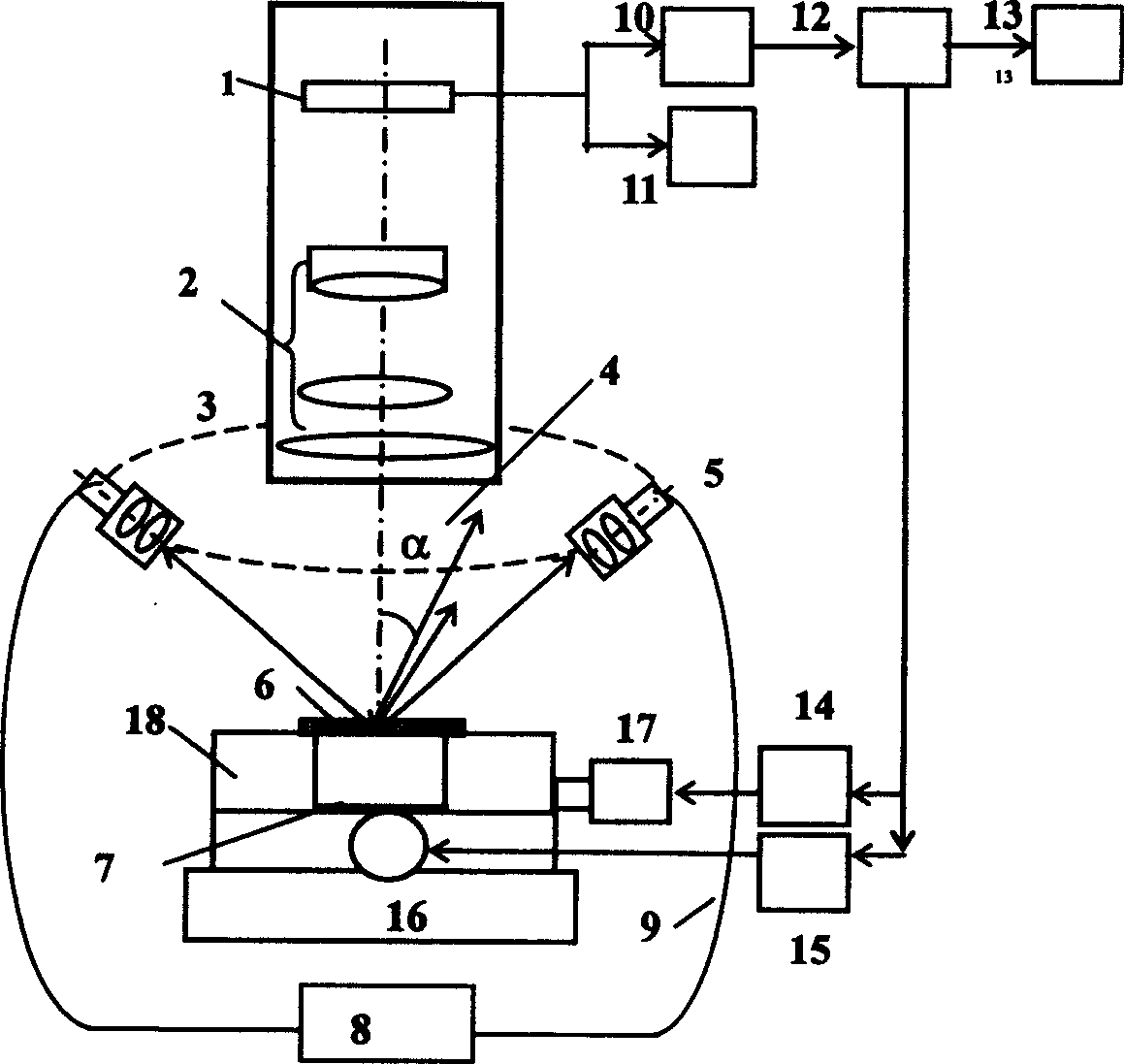

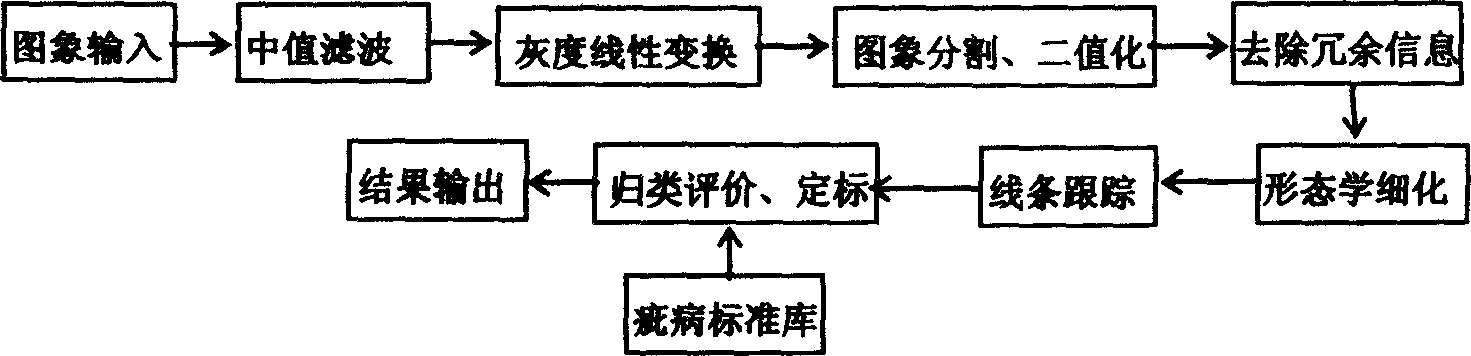

[0060] The automatic detection method and system of the smooth surface defect of the present invention are as attached figure 1 As shown, when the diameter of the tested surface is small, the tested component 6 is placed on the workbench 18, and the dark background 7 is under the tested component. The adjustable frame 3 enables the fiber optic light source (the light source is an incandescent lamp and can be adjusted in light intensity) 9 to irradiate the tested component at a specific angle, and the incident light is reflected by the surface on the object surface of the optical system and emerges from the other end, while the surface Part of the scattered light induced by the edge of the defect is reflected at an angle of α and then collected by the zoom optical micro-magnification system 2 and imaged on the CCD1. One path of the image passes through the monitor 11 for monitoring during detection, and the other path passes through the image acquisition system 10 to send the c...

Embodiment 2

[0062] When the diameter of the surface to be tested is large, the automatic detection system for smooth surface defects is shown in Figure 1, and the placement and adjustment of the tested components are as in Example 1. When the surface to be measured is a large diameter, it can be carried out as attached Figure 4 In the scanning mode shown, the computer 12 controls the driving circuits 14, 15 of the X and Y worktables of the sub-aperture scanning, so that the X and Y motors 16 and 17 drive the worktable 18 to perform multiple sub-aperture scans in the X and Y directions. Obtain full aperture defect image data. And the sub-aperture mosaic is completed according to the coordinates of each scanning aperture. Large-aperture detection must be composed of multiple sub-apertures, so the amount of data is very large. In order to compress the amount of data, the sub-apertures with no defect information can be removed, and at the same time, the requirements between the accuracy of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com