Polymer type phosphatic fire retardant, preparation method and usage

A flame retardant and polymer technology, applied in the field of polymer-type phosphorus-containing flame retardants and their preparation, can solve problems such as difficulty in adding, and achieve the effects of excellent flame retardant effect, excellent durability, and difficult migration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

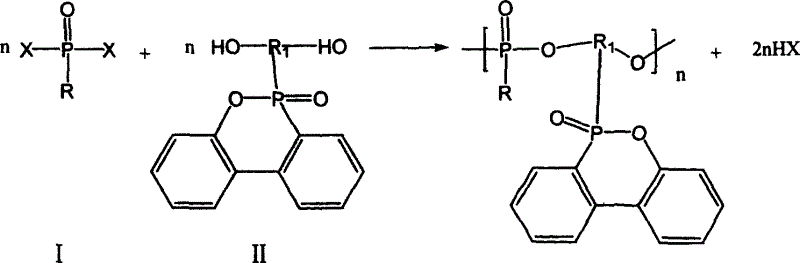

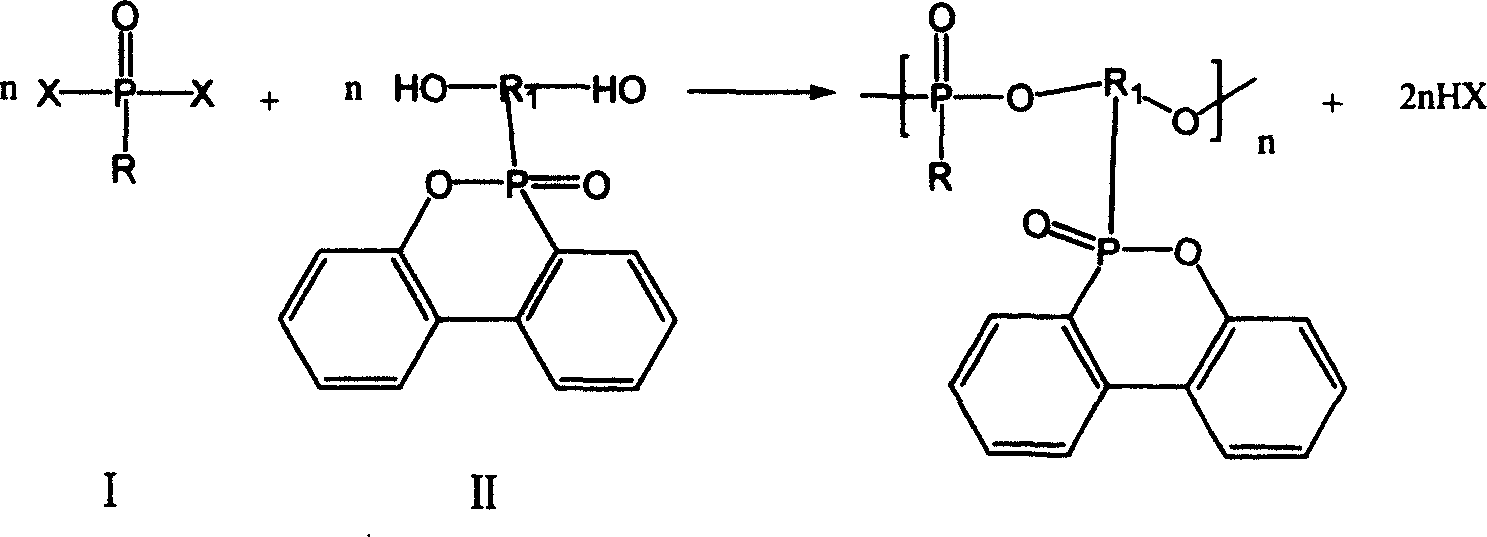

Method used

Image

Examples

Embodiment 1

[0021] Add 1 mole of phenylphosphonic dichloride, 1 mole of 9,10-dihydro-9-oxa-10-phosphophenanthrene-hydroquinone (hereinafter referred to as ODOP-HQ), and 0.01 mole of calcium chloride In a reaction kettle with a stirrer and a thermometer, feed nitrogen gas and stir to raise the temperature to 160°C for 1 hour; then raise the temperature to 250°C for 3 hours; Precipitate in diethyl ether, filter and vacuum-dry to obtain a white crystalline product. The yield was 99%, and the melting temperature was 200°C.

Embodiment 2

[0023] Add 1 mole of naphthylphosphonodibromide, 1 mole of ODOP-HQ, and 0.05 moles of calcium chloride into a reaction kettle equipped with a stirrer and a thermometer, feed in nitrogen and stir to raise the temperature to 180°C for 2 hours; then raise the temperature to 250°C Reaction at ℃ for 4 hours; after cooling, add 250ml of benzyl alcohol to dissolve it completely, then pour into 8 times the volume of anhydrous methanol to precipitate, filter and vacuum dry to obtain a white powder product. The yield was 98%, and the melting temperature was 220°C.

Embodiment 3

[0025] Put 1 mole of phenylphosphonodibromide, 1.1 moles of ODOP-HQ, and 0.02 moles of zinc chloride into a reaction kettle equipped with a stirrer and a thermometer, feed in nitrogen and stir to raise the temperature to 160°C for 1 hour; then raise the temperature to 250°C React at ℃ for 5 hours; after cooling, add 150ml of tetrachloroethane to dissolve it completely, then pour it into 7 times the volume of anhydrous ether to precipitate, filter and vacuum dry to obtain a white crystalline product. The yield was 95%, and the melting temperature was 200°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com