Method for extracting high active immunoglobulin in blood

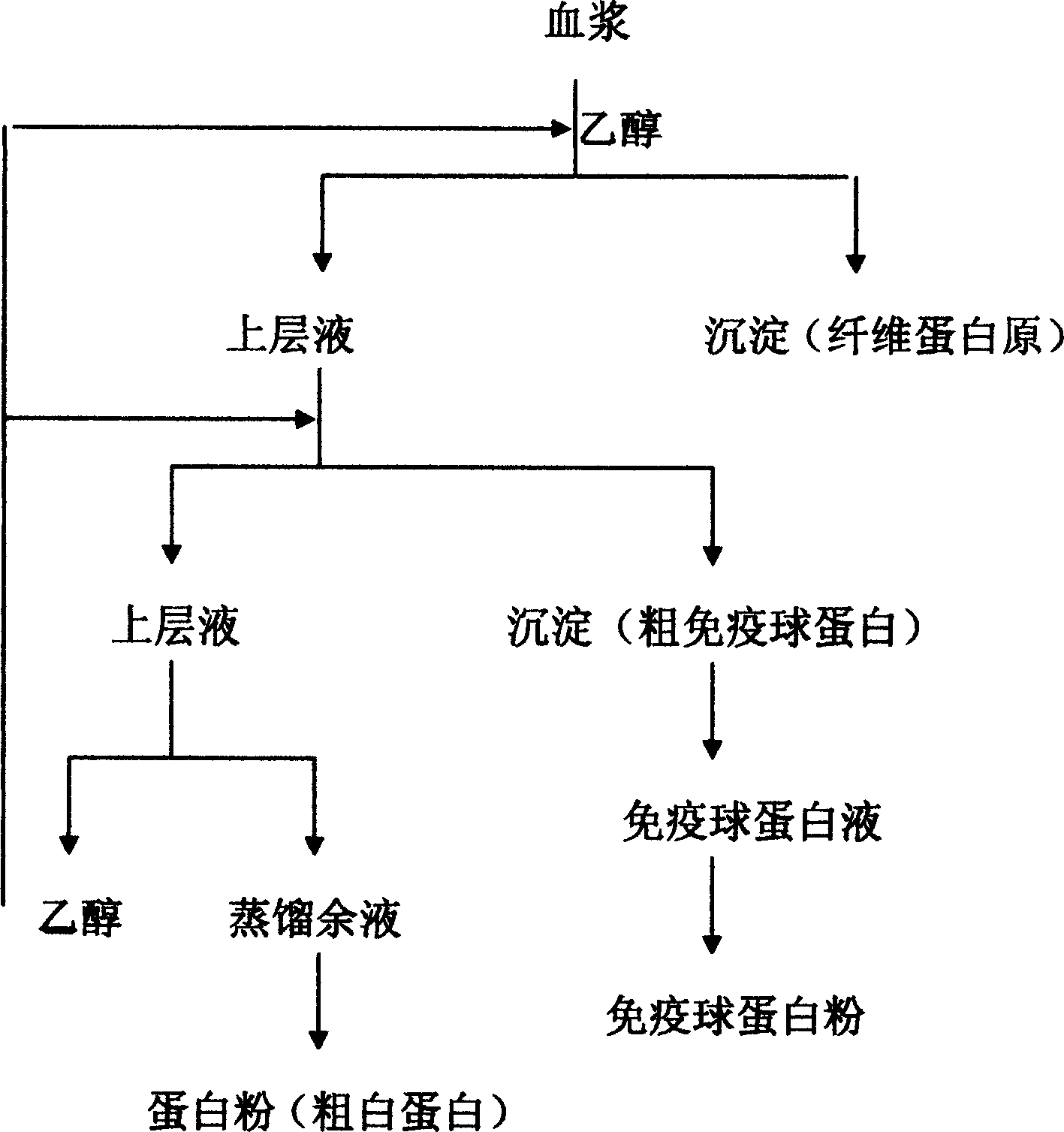

A technology of immunoglobulin and extraction method, which is applied in the field of extraction of highly active immunoglobulin in blood, can solve the problems of cumbersome extraction steps, low immunoglobulin content, and long time, so as to simplify production steps, simplify extraction steps, reduce pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0013] Get 500g blood, at ethanol concentration 8% (mass ratio), precipitation removes fibrin under pH7.2; Then adjust ethanol concentration to 25% (mass ratio); Add distilled water to 500g, stir and dissolve, and ultrafilter three times by dilution ultrafiltration to obtain 150g of ultrafiltrate; obtain 9.2g of high-activity immunoglobulin powder by freeze-drying. The supernatant after extracting the immunoglobulin was vacuum distilled at 45° C. and 0.1 Mpa to obtain 300 g of a recovered solution containing 72.5% ethanol. The remaining solution of distillation obtains protein powder 28.6g (mainly albumin) through spray-drying, can make the content of protein and be the feed powder of the high protein of 69.2%.

example 2

[0015] Get 500g of blood, at a concentration of 12% acetone (mass ratio), precipitate and remove fibrin at pH7; then adjust the acetone concentration to 28% (mass ratio); precipitate immunoglobulin at pH5.6, in crude immunoglobulin Add distilled water to 500g, stir to dissolve, and ultrafilter three times by dilution ultrafiltration to obtain 150g of ultrafiltrate; obtain 10.1g of immunoglobulin powder by freeze-drying. The supernatant after the immunoglobulin extraction was vacuum distilled at 48° C. under 0.1 Mpa to obtain 300 g of a recovered solution containing 72.5% acetone. Re-distilling the remaining solution to obtain protein powder 27.6g (mainly albumin) through spray-drying, can be made into a high-protein feed powder with a protein content of 68.3%.

example 3

[0017] Take 500g of blood, and remove fibrin by precipitation at pH 7.5 at a polyethylene glycol concentration of 15% (mass ratio); then adjust the polyethylene glycol concentration to 35% (mass ratio); precipitate immunoglobulin at pH 6.3 , add distilled water to the crude immunoglobulin to 500g, stir and dissolve, and ultrafilter three times by dilution ultrafiltration to obtain 150g of ultrafiltrate; obtain 8.9g of immunoglobulin powder by freeze-drying. The supernatant after the immunoglobulin extraction was vacuum distilled at 50° C. and 0.1 MPa to obtain 300 g of a recovered solution containing 72.5% polyethylene glycol. Re-distilling the remaining solution to obtain protein powder 28.9g (mainly albumin) through spray drying, which can be made into a high-protein feed powder with a protein content of 69.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com