Method for fabricating plates made from fine concrete modified by epoxy emulsion

A technology of fine concrete and epoxy emulsion, which is applied in the field of epoxy emulsion modified cement fine concrete to make plates, which can solve the problem of high viscosity of the system, poor curing effect, flexural strength, waterproof and anti-penetration, which cannot meet the ideal design requirements And other problems, to achieve the effect of improving the flexural strength, saving the amount of addition, and excellent water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

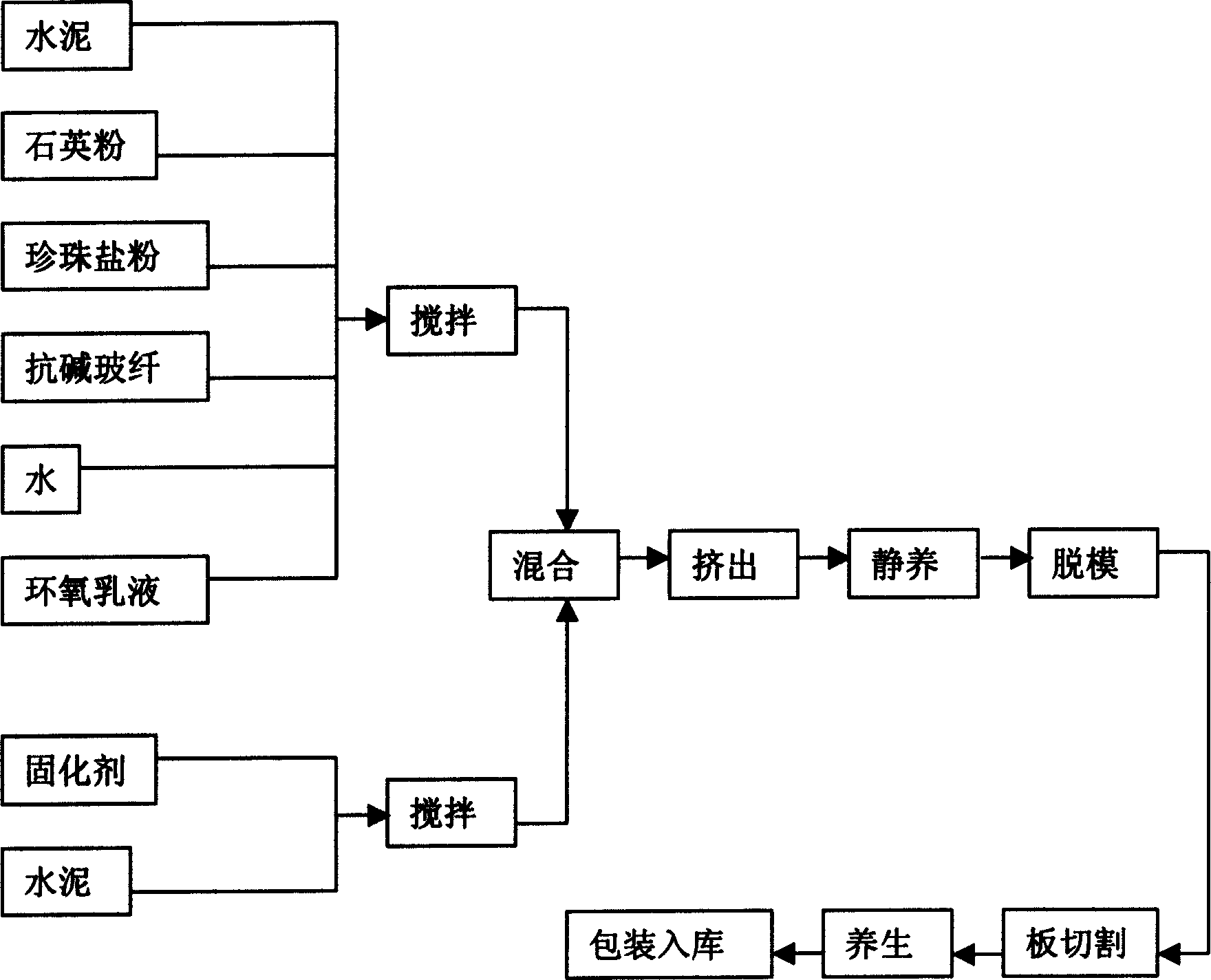

Image

Examples

Embodiment 1

[0042] Take 100 kg of cement, poly-ash ratio 20:100, and water-cement ratio 33:100. From this, it is determined: cement I is 82.35 kg, cement II is 17.65 kg, quartz powder is 65.88 kg, pearl salt powder is 4.69 kg, alkali resistance The glass fiber is 1.56 kg, the epoxy emulsion is 28.24 kg, the curing agent is 5.88 kg, and the supplementary water is 18.88 kg. Mix epoxy emulsion and supplementary water into cement I, quartz powder, pearl salt powder and alkali-resistant glass fiber and stir, after 30 minutes of mixing, epoxy cement slurry is formed; After 30 minutes of full mixing under the addition; the added curing agent was added to the epoxy cement slurry, and after 15 minutes of full mixing, the cement concrete formed a paste-like epoxy network intercalation structure. Cement stone; and then made into boards by a board forming machine. The boards are removed at room temperature (25°C) for 48 hours. After curing for 5 to 7 days, they are trimmed according to specifications...

Embodiment 2

[0045] Take 100 kg of cement, the poly-ash ratio is 45:100, and the water-cement ratio is 33:100. From this, it is determined that: cement I is 60.29 kg, cement II is 39.71 kg, quartz powder is 48.23 kg, pearl salt powder is 3.44 kg, alkali resistance The glass fiber is 1.15 kg, the epoxy emulsion is 63.52 kg, the curing agent is 13.24 kg, and the supplementary water is 1.24 kg. Mix epoxy emulsion and supplementary water into cement I, quartz powder, pearl salt powder and alkali-resistant glass fiber and stir, after 30 minutes of mixing, epoxy cement slurry is formed; After 30 minutes of full mixing under the addition; the added curing agent was added to the epoxy cement slurry, and after 10 minutes of full mixing, the cement concrete formed a paste-like epoxy network intercalation structure. Cement stone; and then made into boards by a board forming machine. The boards are removed at room temperature (25°C) for 48 hours. After curing for 5 to 7 days, they are trimmed accordin...

Embodiment 3

[0048] Take 100 kg of cement, poly-ash ratio 33:100, and water-cement ratio 33:100. From this, it is determined: cement I is 70.88 kg, cement II is 29.12 kg, quartz powder is 56.7 kg, pearl salt powder is 4 kg, alkali resistance The glass fiber is 1.35 kg, the epoxy emulsion is 46.6 kg, the curing agent is 9.7 kg, and the supplementary water is 9.7 kg. Mix epoxy emulsion and supplementary water into cement I, quartz powder, pearl salt powder and alkali-resistant glass fiber and stir, after 30 minutes of mixing, epoxy cement slurry is formed; After 30 minutes of full mixing under the addition; the added curing agent was added to the epoxy cement slurry, and after 15 minutes of full mixing, the cement concrete formed a paste-like epoxy network intercalation structure. Cement stone; and then made into boards by a board forming machine. The boards are removed at room temperature (25°C) for 48 hours. After curing for 5 to 7 days, they are trimmed according to specifications and can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Modulus of rupture | aaaaa | aaaaa |

| Tensile properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com