Production method of multi-nutrient green manure of controlling releasing

A production method and nutrient technology, which can be applied to fertilizer forms, fertilizer mixtures, and fertilization devices, etc., can solve the problems of difficulty in meeting the balance of various nutrients of plants, low nitrogen utilization rate of controlled-release nitrogen fertilizers, and high product costs, and improve the Fertilizer nutrient utilization efficiency, ensuring production safety and ecological environment safety, and reducing the effect of fertilizer input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

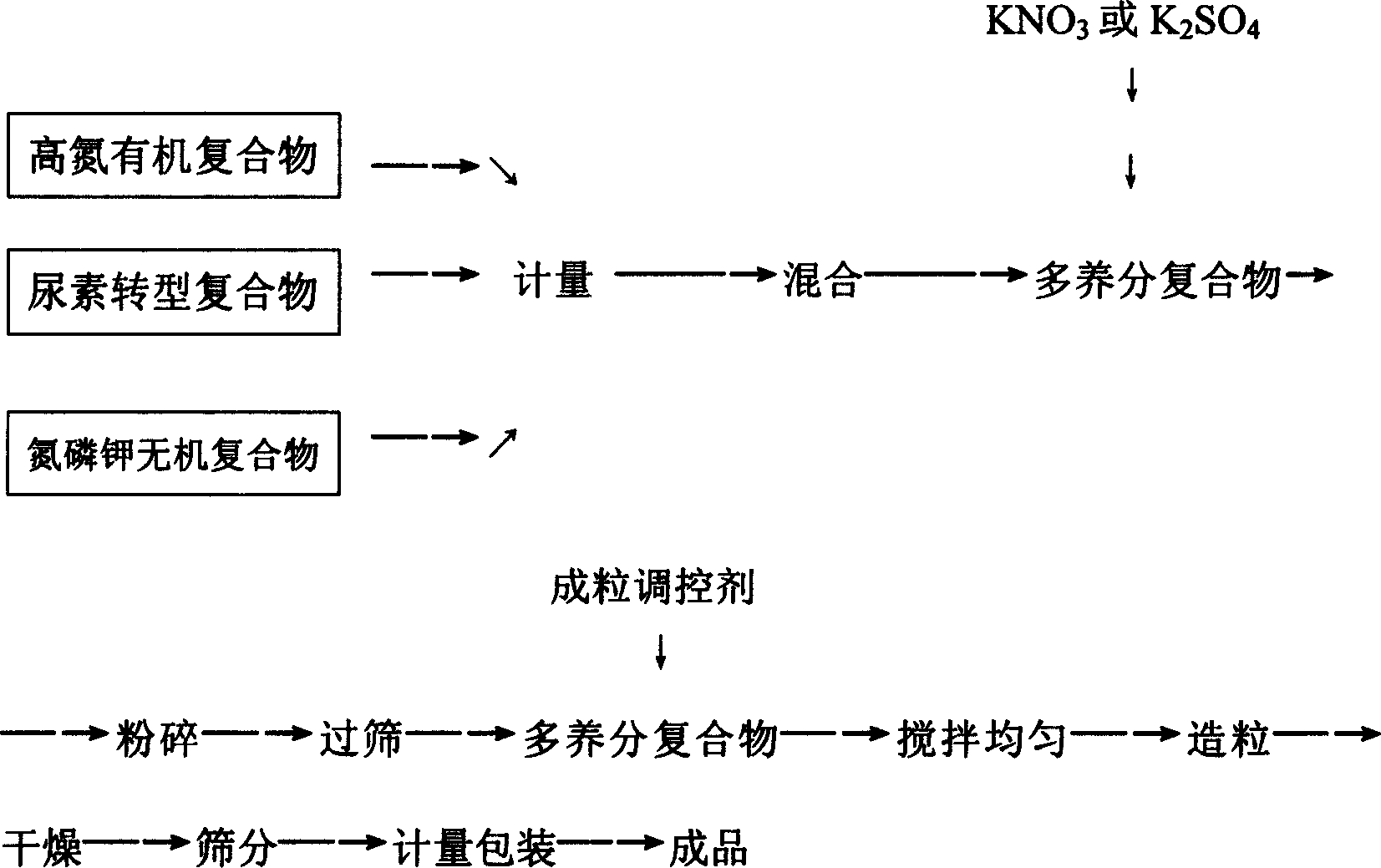

Method used

Image

Examples

Embodiment 1

[0022] a. Mix rapeseed meal, fish meal, and feather meal with particles ≤0.25mm in any mass ratio, add urea 0.8 times the mass, stir evenly, and then add an equal volume of 5mol / l H 2 SO 4 , 4mol / l H 3 PO 4 and 2mol / l HNO 3 The rapid decomposer is composed so that the mass ratio of organic matter and decomposer is 1:0.4, fully stirred evenly, and reacted at 60°C for 48 hours, adding bone powder with a mass ratio of 40%, mixed and balanced for 8 hours.

[0023] b. By mass, get 30% urea, add 20% concentrated sulfuric acid, add 40% bone charcoal and 10% bone meal after the reaction is complete, stir evenly, and cool to room temperature.

[0024] c. In terms of mass, take 57% of KH 2 PO 4 , 28% NH 4 h 2 PO 4 and 15% dicyandiamide, add 0.5 times water, dissolve it at 80°C, cool, dehydrate and dry.

[0025] d. Take 45 parts, 16 parts, 20 parts and KNO of the three components of a, b and c 3 10 parts, mixed evenly, passed through a 0.4mm sieve, added 9 parts of zeolite and ...

Embodiment 2

[0027] a. Mix rapeseed meal, fish meal, and feather meal with particles ≤ 0.25mm in any mass ratio, add 0.6 times the mass of urea, stir evenly, and then add an equal volume of 4mol / l H 2 SO 4 , 4mol / l H 3 PO 4 and 5mol / l HNO 3 The rapid decomposer is composed so that the mass ratio of organic matter and decomposer is 1:0.5, fully stirred evenly, and reacted at 50°C for 48 hours, adding bone meal with a mass ratio of 25%, mixed and balanced for 12 hours.

[0028] b. By mass, get 25% urea, add 20% concentrated sulfuric acid, add 45% bone charcoal and 10% bone meal after the reaction is complete, stir evenly, and cool to room temperature.

[0029] c. In terms of mass, take 58% of KH 2 PO 4 , 30% NH 4 h 2 PO 4 and 12% dicyandiamide, add 1 times water, dissolve it at 70°C, cool, dehydrate and dry.

[0030] d. Take 32 parts, 18 parts, 25 parts and K of the three components of a, b and c 2 SO 415 parts, mix evenly, pass through a 0.4mm sieve, add 10 parts of zeolite and s...

Embodiment 3

[0032] a. Mix rapeseed meal, fish meal, and feather meal with particles ≤ 0.25mm in any mass ratio, add urea 0.7 times the mass, stir evenly, and then add an equal volume of 3mol / l H 2 SO 4 , 4mol / l H 3 PO 4 and 4mol / l HNO 3 The rapid decomposer is composed so that the mass ratio of organic matter and decomposer is 1:0.6, fully stirred evenly, and acted at 55°C for 48 hours, adding bone meal with a mass ratio of 36%, mixed and balanced for 6 hours.

[0033] b. By mass, get 32% urea, add 18% concentrated sulfuric acid, add 35% bone charcoal and 15% bone meal after the reaction is complete, stir evenly, and cool to room temperature.

[0034] c. By mass, take 45% of KH 2 PO 4 , 40% NH 4 h 2 PO 4 and 15% dicyandiamide, add 0.8 times water, dissolve it at 75°C, cool, dehydrate and dry.

[0035] d. Take 35 parts, 16 parts, 22 parts and KNO of the three components of a, b and c 3 15 parts, mix evenly, pass through a 0.4mm sieve, add 12 parts of zeolite and starch mixture (m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com