Method of leaching copper in copper containing pyrite using bacteria

A technology for iron ore and pyrite, applied in the field of bacterial leaching of copper in copper-bearing pyrite, can solve the problems of pH drop, copper leaching rate slowdown, sulfur reduction, etc. Quality improvement, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

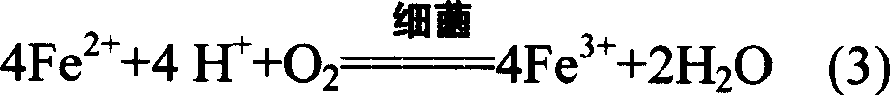

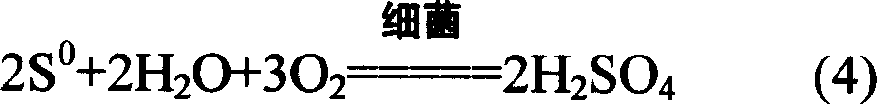

[0032] Example 1 Bacterial Leaching of Copper in Copper-bearing Pyrite

[0033] (1) As a heap, arrange the fine muddy copper-bearing pyrite and the massive copper-bearing pyrite in a ratio of 1:2, and make a pile in layers. The thickness of the fine muddy pyrite layer is 1.5m, and the massive pyrite The thickness of the ore layer is 2.7m; heaped into 600 tons of bacterial leaching heap with an average copper grade of about 0.4%; the heap absorbs water of 38m 3(2) seed culture and leaching solution nutrient preparation mainly cultivate Thiobacillus ferrooxidans, the medium used is the ore pulp of 10% (w / v), add ammonium sulfate 4g / L, dipotassium hydrogen phosphate 0.5g / L, The pH value is 2.0. The preparation of the leaching solution: the addition amount of ammonium sulfate and dipotassium hydrogen phosphate is 5g / L and 0.4g / L respectively, and a small amount of sulfuric acid is added to adjust the pH value to 2.0; during the whole leaching process, the concentration of iron io...

Embodiment 2

[0035] Example 2 Bacterial leaching of copper and zinc in copper-zinc sulfide-containing pyrite

[0036] (1) Make a heap: Pyrite containing copper-zinc sulfide and fine muddy pyrite with an oxidation rate of about 30% and a copper grade of about 0.8% are layered and piled up in a ratio of 1:1; fine muddy pyrite In the upper layer, the copper-zinc sulfide-containing pyrite is in the lower layer, so that sulfuric acid can leach the copper oxide in the upper layer, and the leached copper ions can catalyze the bacterial leaching of zinc in the lower layer, thereby accelerating the bacterial leaching of copper in the copper-zinc sulfide; each layer 2m thick, piled up to 500 tons; (2) Seed bacteria culture and leaching solution nutrient preparation The seed bacteria use Thiobacillus ferrooxidans, Ferrobacterium oxidans, Ferrobacterium thiooxidans, the medium used is 8% (w / v) Add ammonium sulfate 5g / L, dipotassium hydrogen phosphate 0.2g / L, and the pH value is 1.5. For the preparati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com