Preparing method for nanometer porous silica thin-membrane

A silicon dioxide, optical thin film technology, applied in optics, optical components, instruments, etc., to achieve the effect of easy control of film thickness, small equipment investment, and uniform film composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

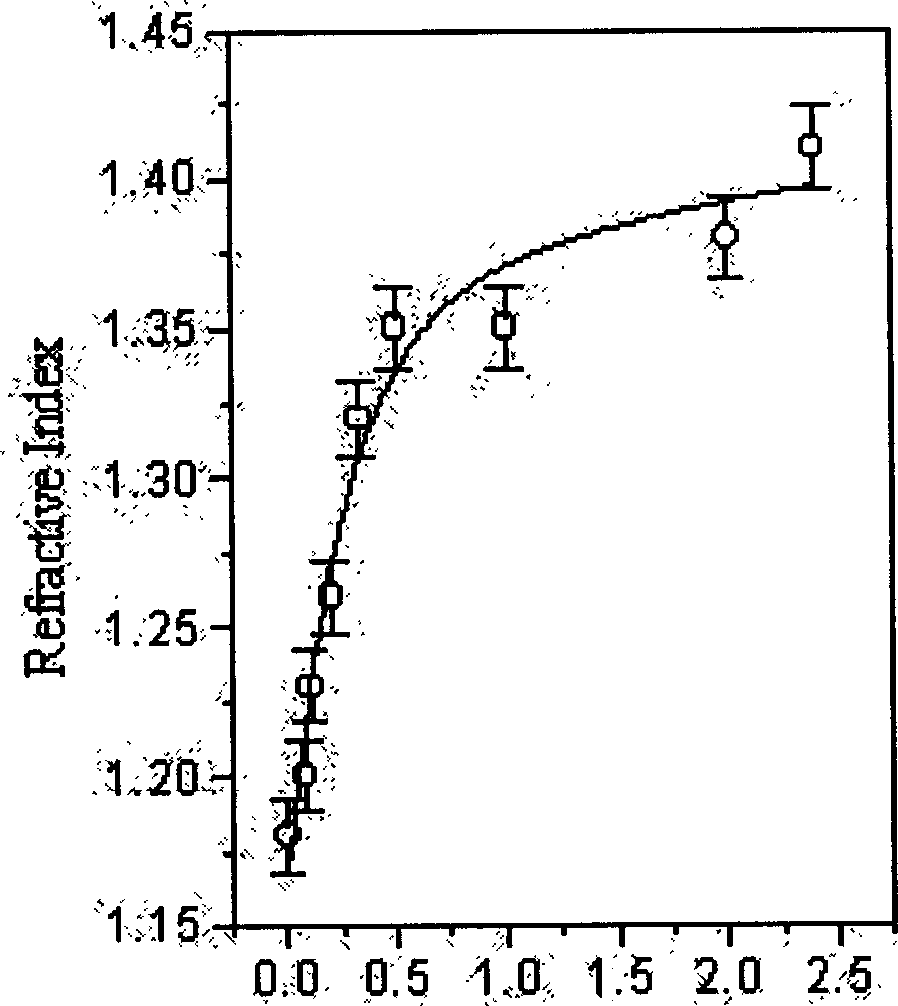

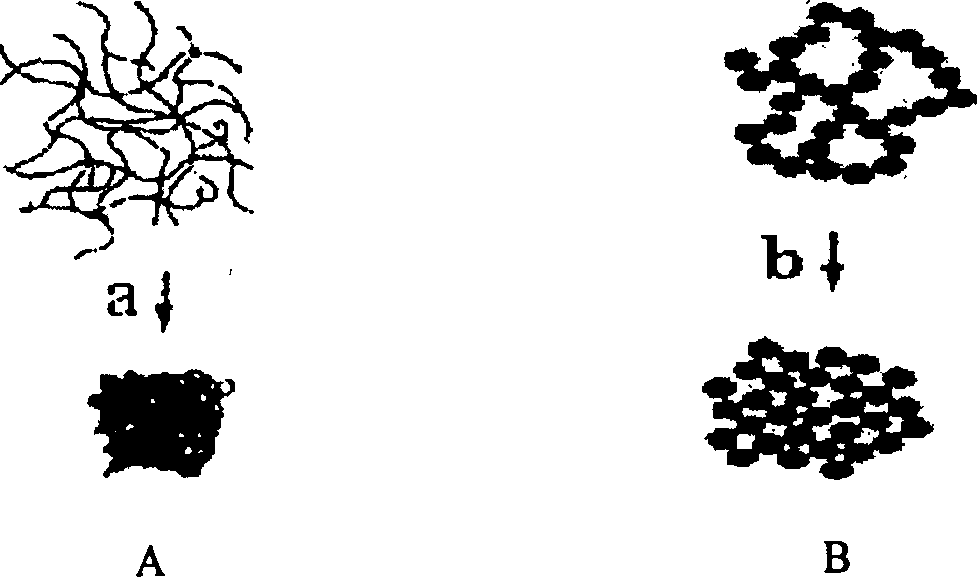

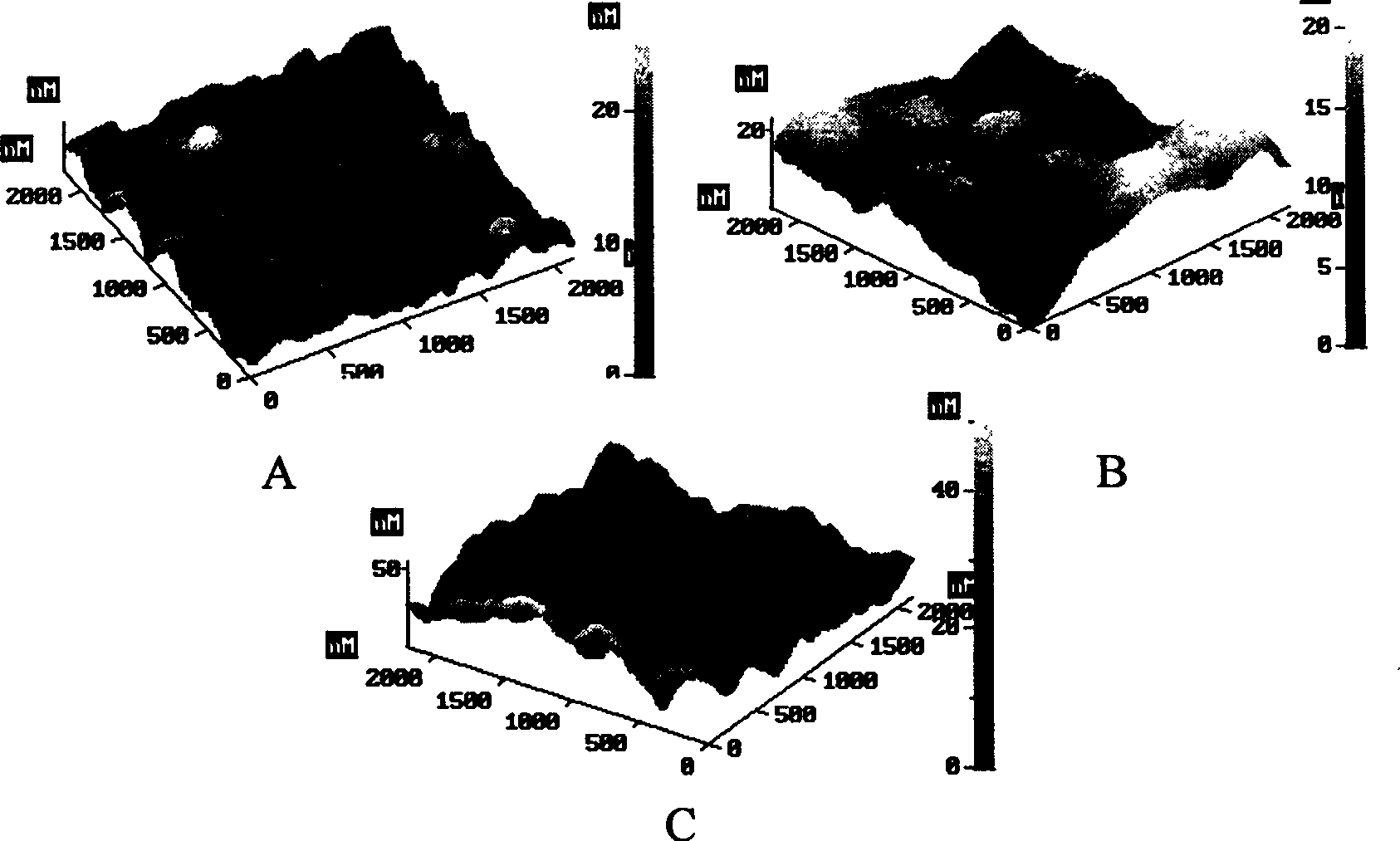

[0016] Embodiment 1: With tetraethyl orthosilicate (TEOS analytically pure), ethanol (adopting anhydrous, analytically pure), water as raw material, ammoniacal liquor as catalyst. First, mix ethyl orthosilicate, ammonia water, ethanol and deionized water at room temperature in a certain molar ratio (1:2.0:35:0.3), stir, and hydrolysis reaction occurs between ethyl orthosilicate and water under the catalysis of ammonia water At the same time, polycondensation reaction occurs between the hydroxyl groups formed in the hydrolysis reaction, and the sol with white opalescence is formed after standing and aging at room temperature for 3 days, and then the sol is refluxed at 80°C for 8 hours to remove the ammonia gas, and the obtained Alkaline SiO 2 Sol. Mix TEOS, hydrochloric acid (pH=1), ethanol and deionized water at a molar ratio of 1:2.3:38:0.245, stir, and leave to age at room temperature for 1.5 days to make acidic SiO 2 Sol. Acidic SiO 2 The sol was added to the basic SiO ...

Embodiment 2

[0017] Embodiment 2: Using ethyl orthosilicate (TEOS analytical grade), dehydrated alcohol (analytical grade), water as raw material, ammonia water as catalyst. Firstly, tetraethyl orthosilicate, ammonia water, ethanol and deionized water are mixed in a certain molar ratio (0.5:1.5:25:0.3), stirred, and left to stand at room temperature for 5 days to form a sol with white opalescence , and then the sol was refluxed at 90°C for 7 hours to remove the ammonia gas and make basic SiO 2 Sol. Mix TEOS, hydrochloric acid (pH=1), ethanol and deionized water at a molar ratio of 0.6:2.0:26:0.145, stir, and leave to age at room temperature for 1 day to form acidic SiO 2 Sol. Acidic SiO 2 The sol was added to the basic SiO at a molar ratio of 2.0:1.0 2 In the sol, mix and stir at room temperature and then reflux for 4.5 hours to obtain SiO with relatively stable performance. 2 Sol. Preparation of SiO on K9 film substrates by dip-pulling method in a clean environment with relative hum...

Embodiment 3

[0018] Embodiment 3: using ethyl orthosilicate (TEOS analytical grade), dehydrated alcohol (analytical grade), water as raw material, ammonia water as catalyst. Firstly, tetraethyl orthosilicate, ammonia water, ethanol and deionized water are mixed in a certain molar ratio (1:2.0:45:0.3), stirred, left to stand and aged at room temperature for 7 days, and a sol with white opalescence is formed. , and then the sol was refluxed at 110°C for 8 hours to remove the ammonia gas and make basic SiO 2 Sol. Mix TEOS, hydrochloric acid (pH=1), ethanol and deionized water at a molar ratio of 0.7:2.1:28:0.165, stir, and leave to age at room temperature for 2 days to form acidic SiO 2 Sol. Acidic SiO 2 The sol was added to the basic SiO at a molar ratio of 1.0:1.0 2 In the sol, mix and stir at room temperature and then reflux for 4 hours to obtain SiO with relatively stable performance. 2 Sol. Preparation of SiO on K9 film substrates by dip-pulling method in a clean environment with r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com