Processing device

A processing device and processing container technology, which is applied in the application of electrostatic attraction holding devices, electrical components, semiconductor/solid-state device manufacturing, etc., can solve problems such as poor uniformity in the plane, maintain a tight state, and inhibit the deterioration of the bonding layer , the effect of suppressing deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

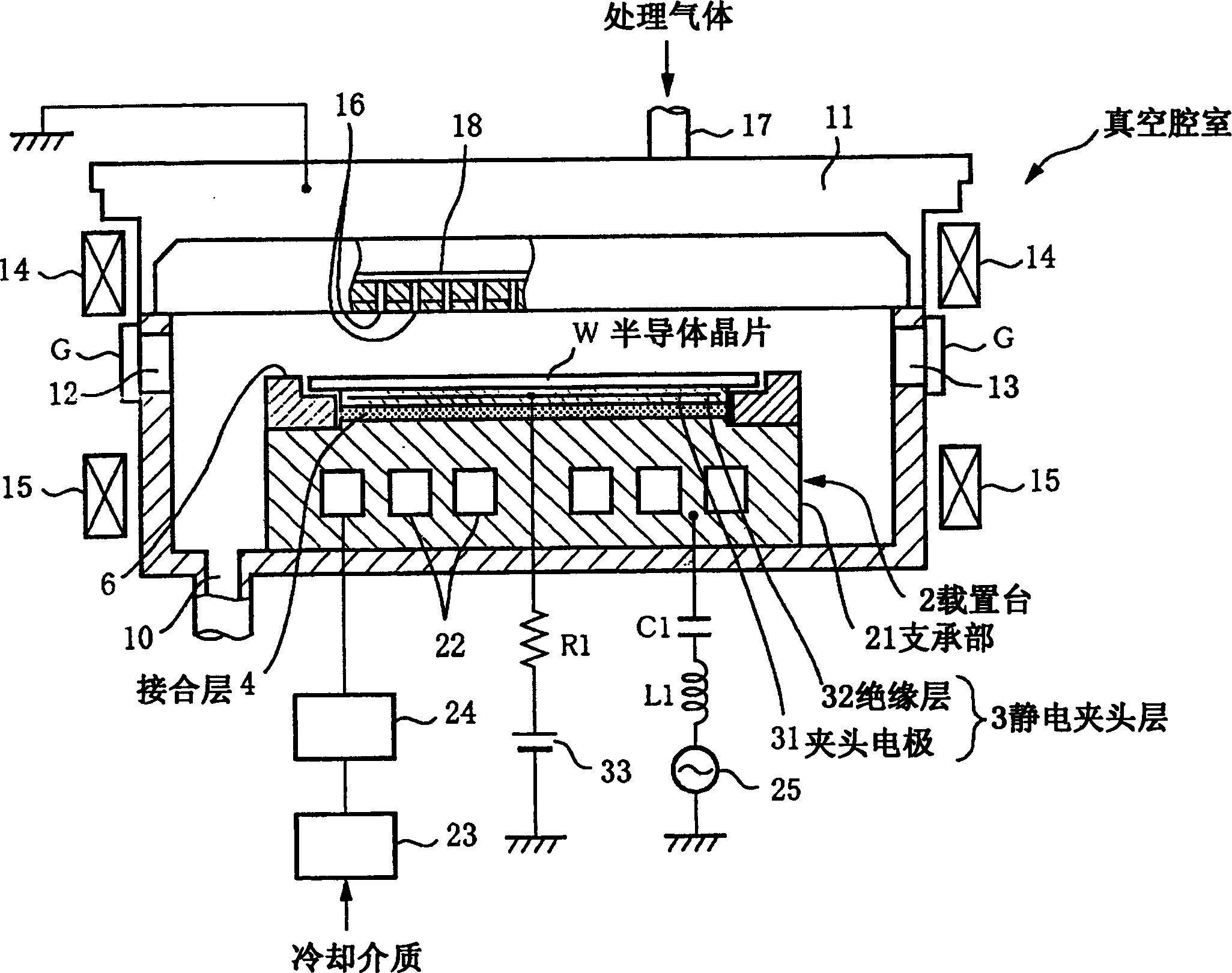

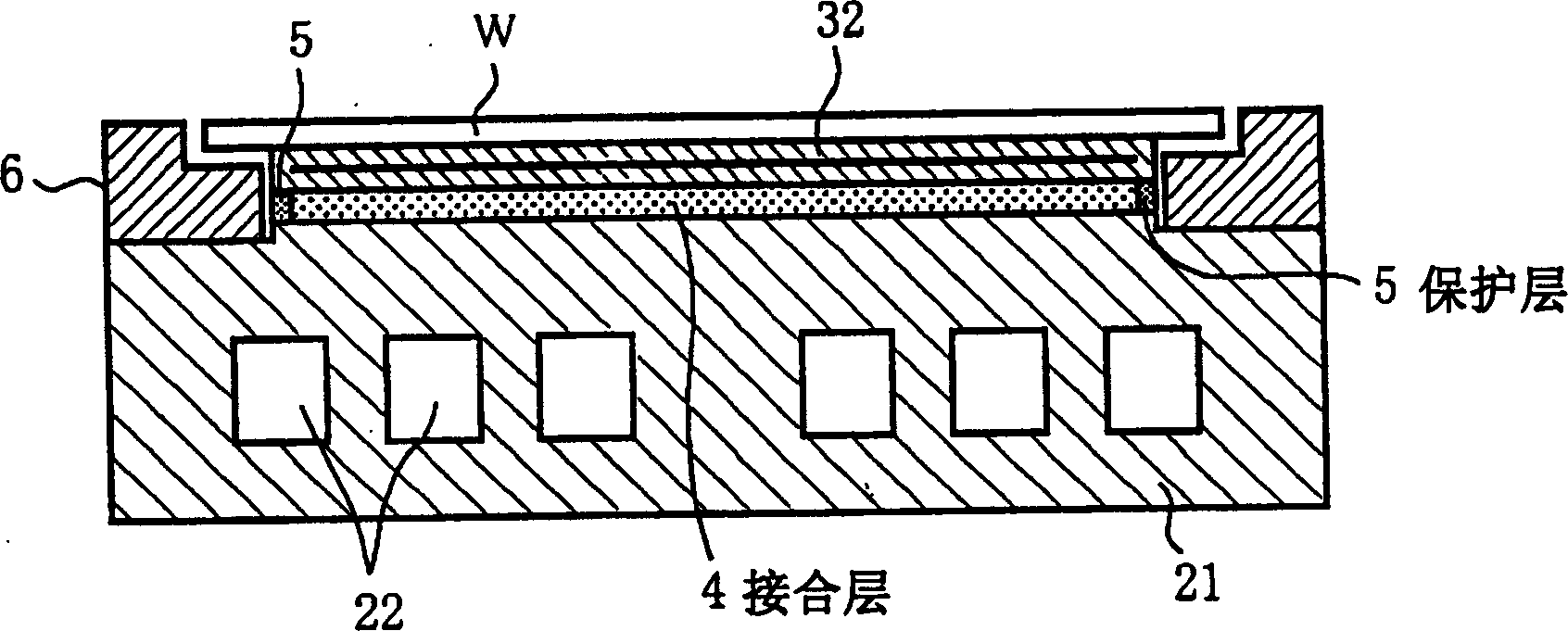

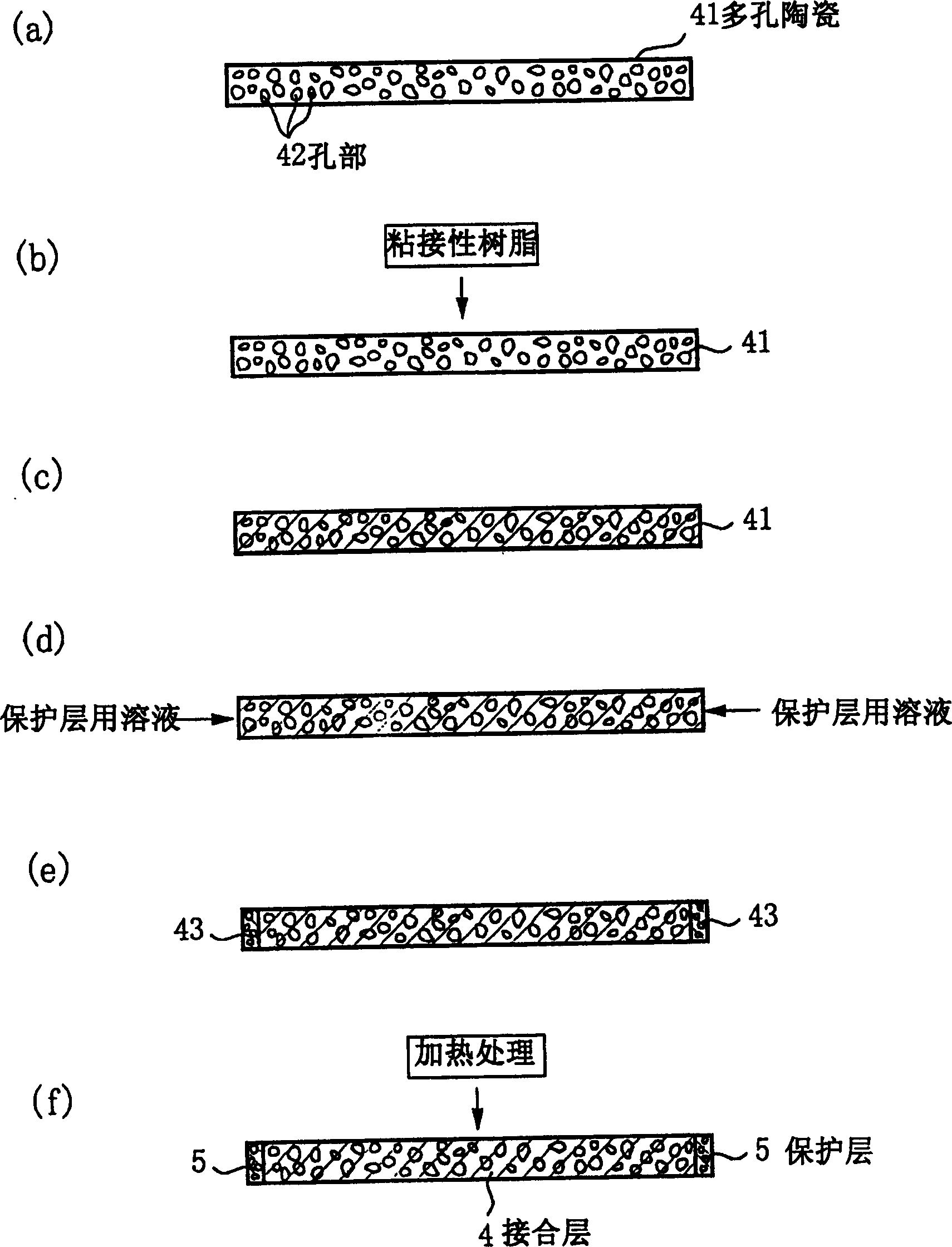

[0060] refer to figure 1 and figure 2 Embodiment 1 of the processing apparatus of the present invention will be described. figure 1 It is a vertical cross-sectional view showing the overall configuration of an example of an etching apparatus as a processing apparatus of this embodiment. 1 in the figure is a vacuum chamber forming a processing container, which may form a sealed structure made of aluminum. In this vacuum chamber 1, an upper electrode 11 serving as a gas shower head (processing gas supply part) and a mounting table 2 serving as a lower electrode are oppositely arranged, and an exhaust port communicating with a vacuum pump not shown in the figure is formed on the bottom surface. 10. Openings 12 and 13 are formed on the side walls of the vacuum chamber 1 for loading and unloading semiconductor substrates such as wafers W which are silicon substrates. The openings 12, 13 can be freely opened and closed by gate valves G, respectively. Ring-shaped permanent mag...

Embodiment approach 2

[0089] Another embodiment of the present invention will now be described. Figure 6 It is a figure which shows the mounting table 7 used in this embodiment. The other parts of the processing apparatus (etching apparatus) of this embodiment and figure 1 have the same structure. exist Figure 6 in, with figure 2 The same symbols denote the same part. The bonding layer 70 is used to bond the electrostatic chuck layer 3 and the support portion 21, and may be made of a silicone rubber-based adhesive. In addition, a flexible covering member 71 is provided on the side peripheral surface of the bonding layer 70 to protect the bonding layer 70 from active species such as fluorine radicals or fluorine ions generated by plasma. Another example will be Figure 6 Part of (a) enlarged Figure 6 As shown in (b), a sprayed coating 72 is formed on the central portion of the upper surface of the support table 21 , that is, on the peripheral edge of the convex portion that is a portion ...

Embodiment approach 3

[0104] Embodiment 3 of the processing apparatus of the present invention will now be described. Figure 9 A vertical cross-sectional view showing the entire structure of a plasma apparatus as a processing apparatus for implementing the present invention is used in an etching apparatus. In the figure, 120 is an airtight processing container made of a conductive material such as aluminum, and the processing container 120 is grounded. In this processing chamber 120, an upper electrode 130 serving as a gas shower head serving as a gas supply unit for introducing a predetermined processing gas, and a mounting table 140 serving as a lower electrode on which a wafer W serving as a substrate to be processed is placed are provided facing each other. An exhaust pipe 121 is connected to the bottom of the processing container 120 , and a vacuum exhaust device such as a vacuum pump 122 such as a turbomolecular pump or a dry pump is connected to the exhaust pipe 121 . In addition, a gate v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com