Ultrafine fibre preparation of taxol and method and apparatus for preparing the same

A technology of microfiber and paclitaxel, which is applied in fiber treatment, medical preparations of non-active ingredients, pharmaceutical formulas, etc., and can solve problems such as susceptibility to infection and pain of patients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

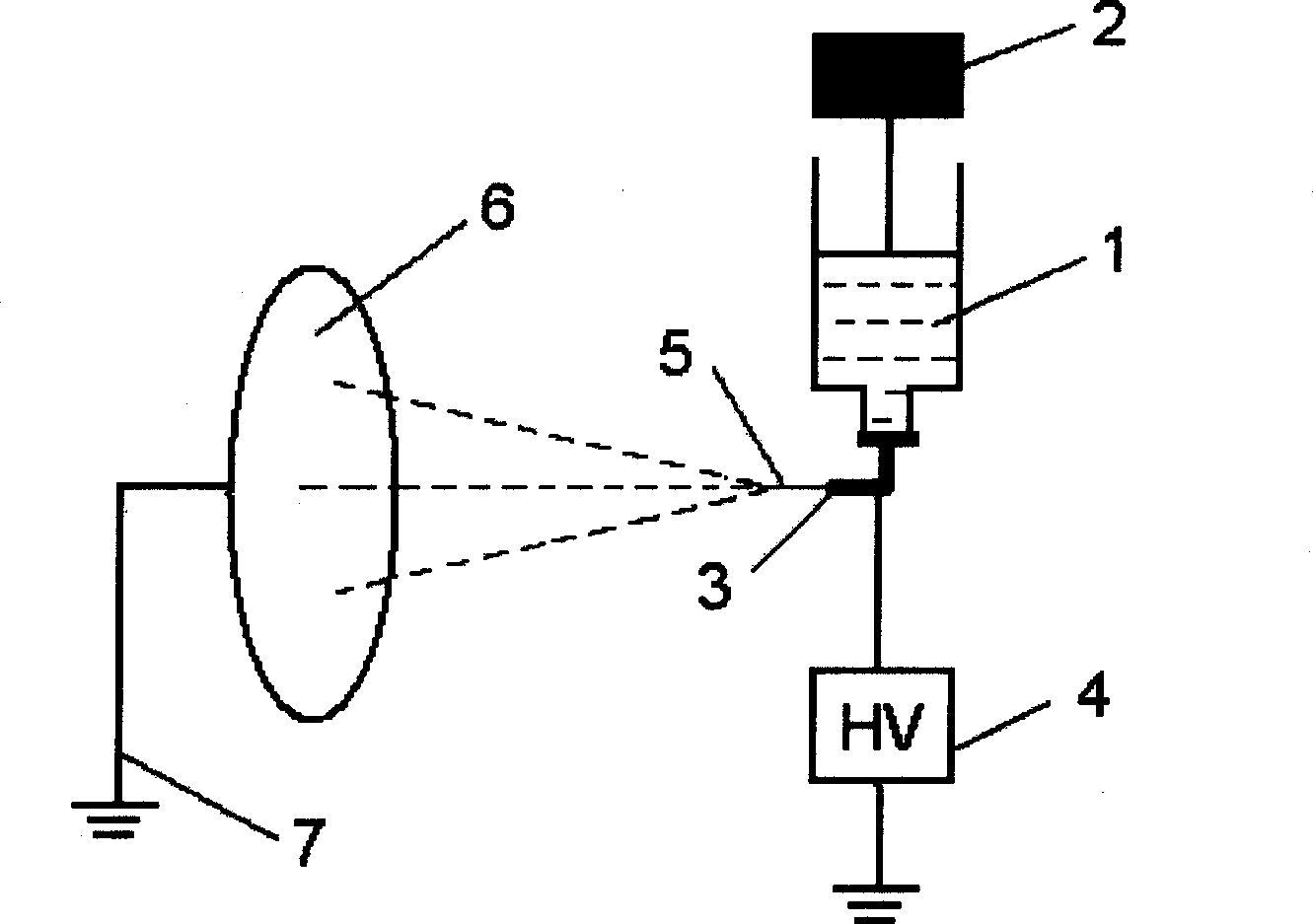

Method used

Image

Examples

Embodiment 1

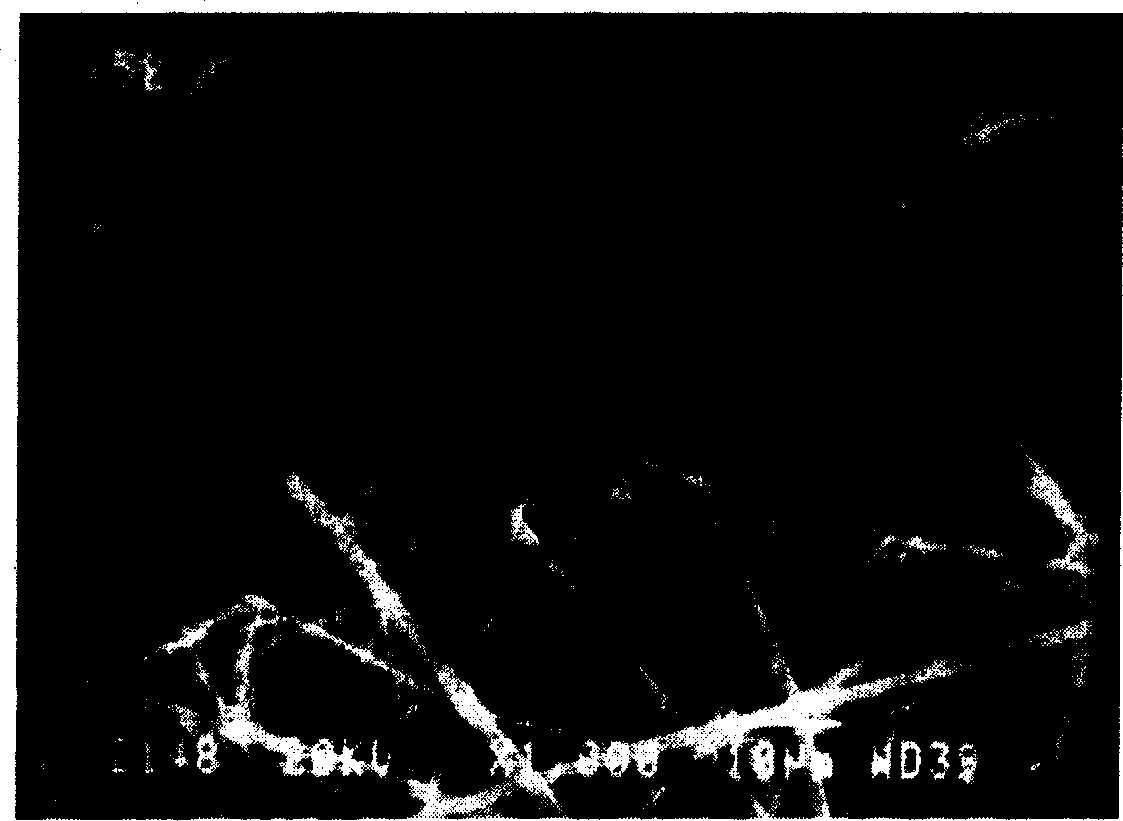

[0025] Embodiment 1. 0.28g polylactic acid PLA (containing D-configuration 2.8%, viscosity-average molecular weight is 91,000) is dissolved in the mixed solvent of 1.5ml chloroform and 1.5ml acetone, then adds 0.014g paclitaxel, ultrasonic vibration makes it Fully dissolve. The solution was then added to a 5 ml syringe, using a right angled flat spinneret made with an 8 gauge needle. The flow rate of the solution at the spinneret is 0.08ml / min, the applied voltage is 26,000 volts, and the distance between the two poles is 20cm.

[0026] The average diameter of the resulting drug-loaded fiber is 800nm, see figure 2 .

Embodiment 2

[0027] Example 2. Dissolve 0.15 g of L-polylactic acid PLLA (viscosity average molecular weight: 153,000) in a mixed solvent of 2 ml of chloroform and 1 ml of acetone, then add 0.015 g of paclitaxel, and ultrasonically oscillate to fully dissolve it. The solution was then added to a 5 ml syringe, using a right angled flat spinneret made with an 8 gauge needle. The flow rate of the solution at the spinneret is 0.07ml / min, the applied voltage is 25,000 volts, and the distance between the two poles is 20cm.

[0028] The average diameter of the resulting drug-loaded fibers is 1.0 μm, see image 3; For its release behavior in Tris-HCl buffer, see Figure 4.

Embodiment 3

[0029]Example 3. Dissolve 0.15 g of polylactic acid PLA (containing D-configuration 2.8%, viscosity-average molecular weight of 91,000) in a mixed solvent of 2 ml of chloroform and 1 ml of acetone, then add 0.075 g of paclitaxel, and ultrasonically vibrate to fully dissolve it . The solution was then added to a 5 ml syringe, using a right angled flat spinneret made with an 8 gauge needle. The flow rate of the solution at the spinneret is 0.1ml / min, the applied voltage is 28,000 volts, and the distance between the two poles is 20cm.

[0030] The average diameter of the obtained drug-loaded fibers was 1.3 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com