Nano hud-type bimetal powder of copper and stannum, preparing method and application

A nano-core-shell, bimetallic technology, applied in botanical equipment and methods, applications, biocides, etc., can solve the problems of elemental nano-copper powder being easily oxidized but not easily oxidized, etc., achieving significant social benefits, friction reduction and energy saving , Excellent anti-wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] First, 2 grams of nano-spherical copper powder was prepared by using the technology reported by Liu Zhijie, Zhao Bin, etc. on pages 55-58 of the 10th issue of the document "Chemical Bulletin" in 1996, and the copper powder was stirred and dispersed evenly with 50 ml of water;

[0023] Polymer protection agent PVP content is 20g / L, tin protochloride dihydrate content is 7g / L, copper complexing agent thiourea content is 50ml of the mixed solution of 60g / L, under the condition of stirring at room temperature, it is mixed with copper Mix the powder suspension. The reaction time is 10 minutes, and the reaction product is filtered, washed and dried. The so-called core-shell copper-tin bimetal nanopowder can be obtained.

[0024] The copper content is 90% and the tin content is 10% as measured by gravimetric analysis.

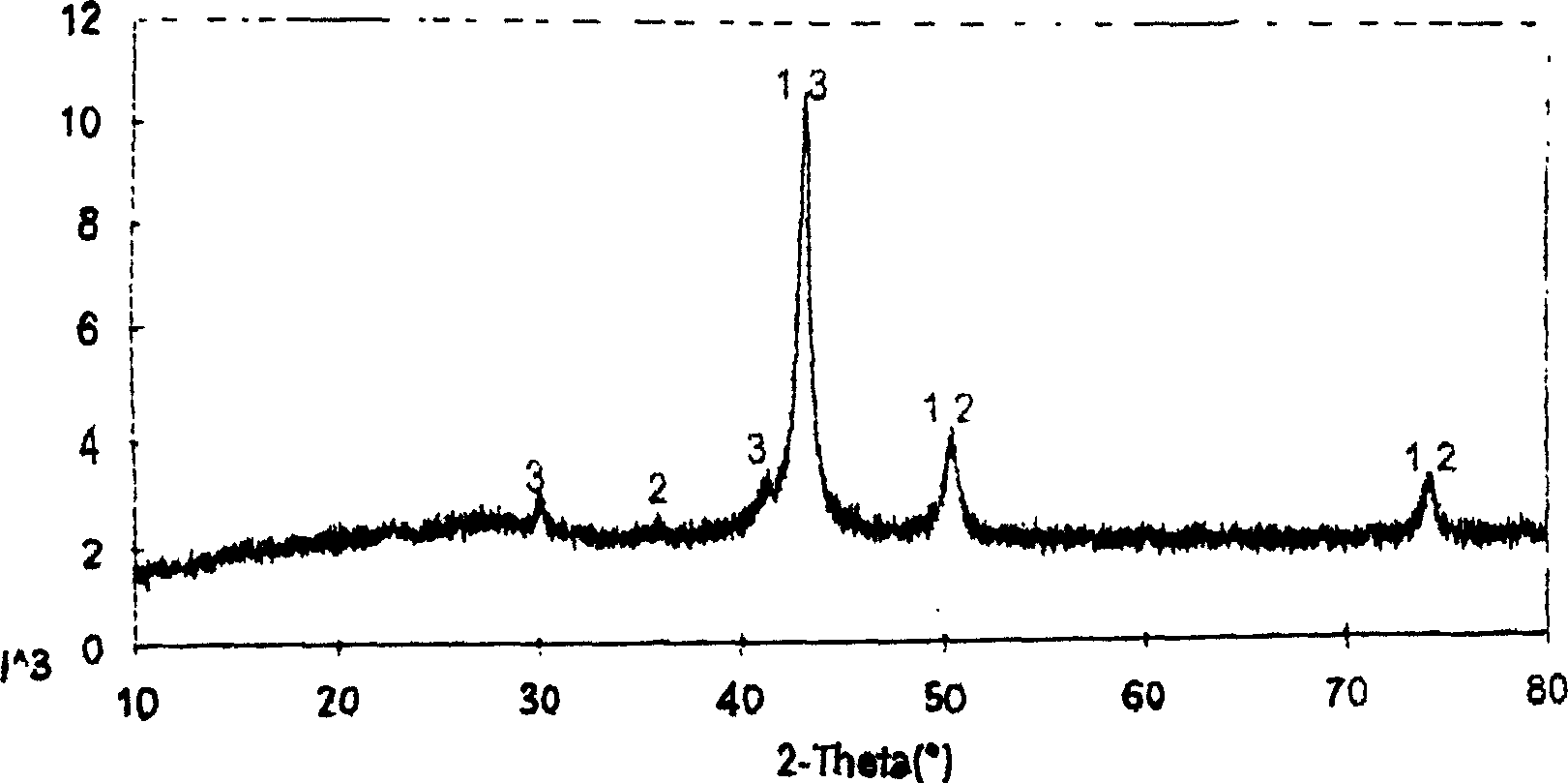

[0025] Depend on figure 1 , 2 The comparison shows that spherical or nearly nano-spherical copper-tin bimetallic powder can be prepared by using nano-spher...

Embodiment 2

[0028] Adopt existing technology to prepare 2 grams of irregular polygonal copper powders with hydrazine hydrate as a reducing agent, and add 50 ml of water to the copper powders and stir to disperse evenly;

[0029] Polymer protection agent PVP content is 20g / L, tin protochloride dihydrate content is 7g / L, copper complexing agent thiourea content is 50ml of the mixed solution of 60g / L, under the condition of stirring at room temperature, it is mixed with copper Mix the powder suspension. The reaction time is 15 minutes, and the reaction product is filtered, washed and dried. The so-called core-shell copper-tin bimetal nanopowder can be obtained.

[0030] The copper content is 90% and the tin content is 10% as measured by gravimetric analysis.

[0031] The morphology of the prepared powder was observed by transmission electron microscope as irregular polygon. This shows that the shape of the raw copper powder determines the shape of the copper-tin powder.

Embodiment 3

[0033] Referring to Example 1, 2 g of nano-spherical copper powder was prepared and made into 50 ml of a suspension.

[0034] Polymer protective agent PVP content is 20g / L, tin protochloride dihydrate content is 17g / L, copper complexing agent thiourea content is 50ml of the mixed solution of 80g / L, under the condition of 60 ℃, stirring it and Copper powder suspension mixed. The reaction time is 10 minutes, and the reaction product is filtered, washed and dried. The so-called core-shell copper-tin bimetal nanopowder can be obtained.

[0035] The copper content is 81% and the tin content is 19% as determined by gravimetric analysis.

[0036] Observed by transmission electron microscope, the prepared powder has a spherical or nearly spherical shape, a single particle size of 50-100nm, and a completely coated structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com