Stacked super condensor and its manufacturing method

A technology of supercapacitor and manufacturing method, applied in capacitor manufacturing, capacitors, electrolytic capacitors, etc., can solve the problems of low power density and energy density of supercapacitors, unsuitable for manufacturing large surface area electrodes, uncontrollable thickness of formed electrode films, etc. It is convenient for large-scale industrial production, good electrochemical performance, and convenient control of electrode forming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

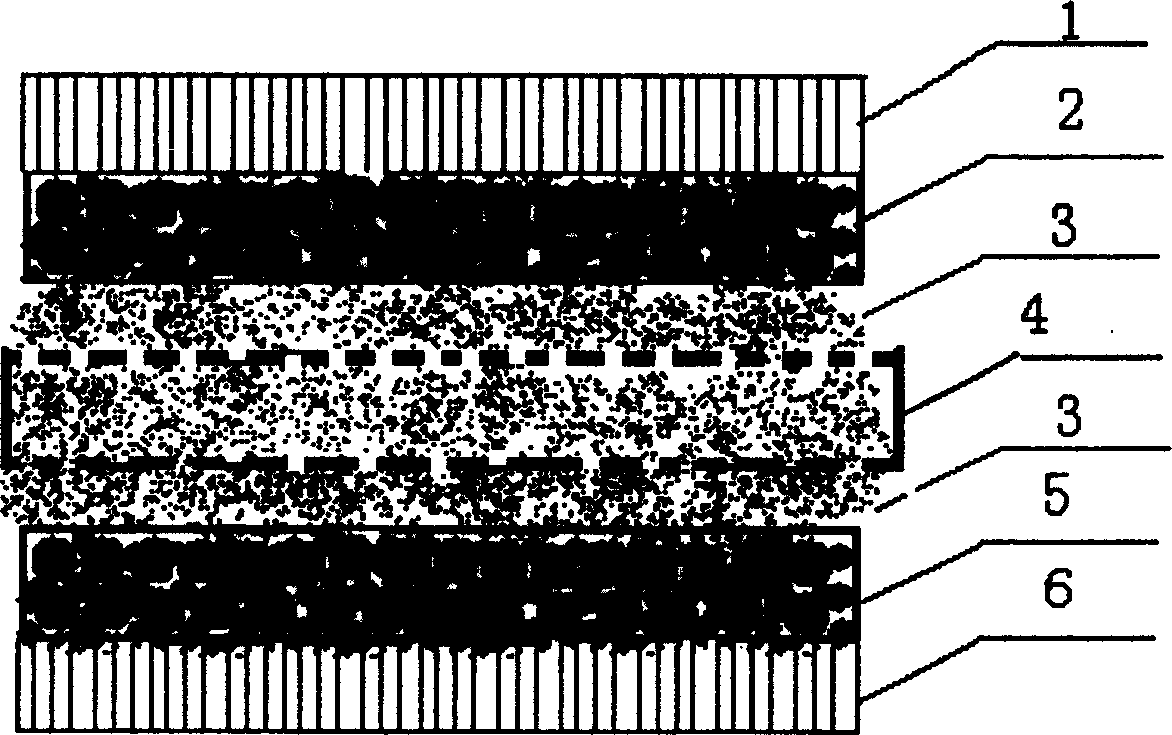

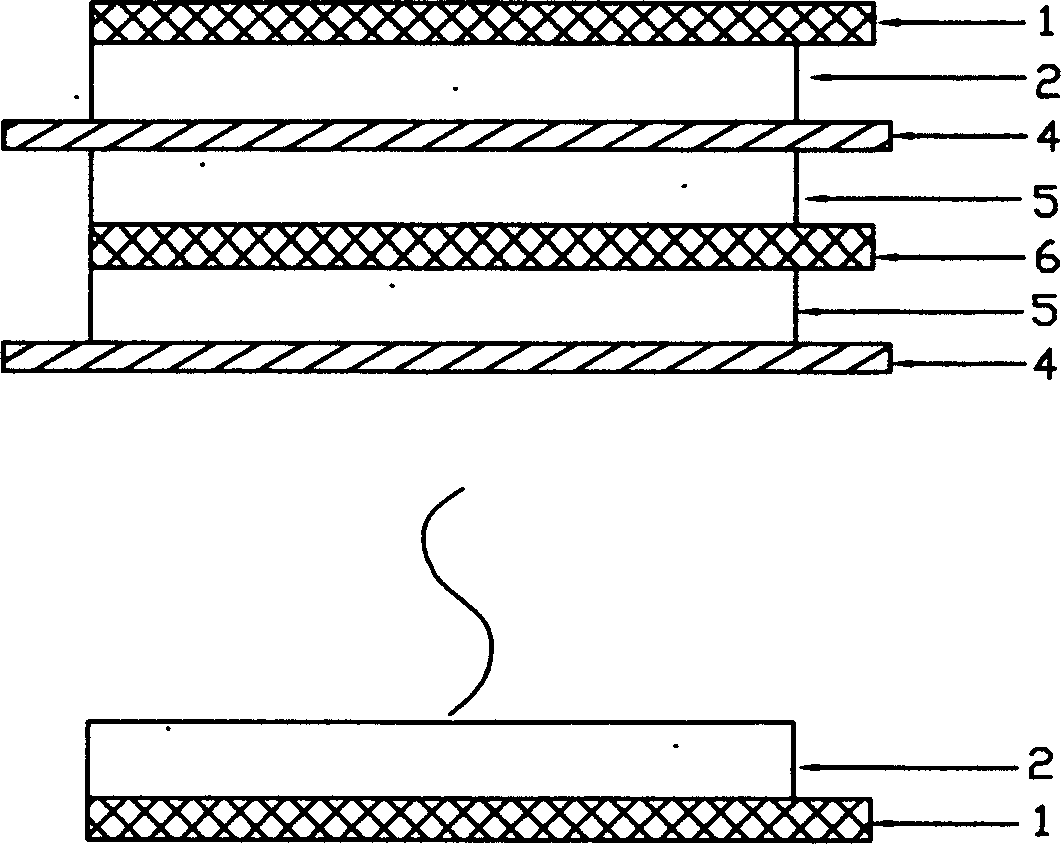

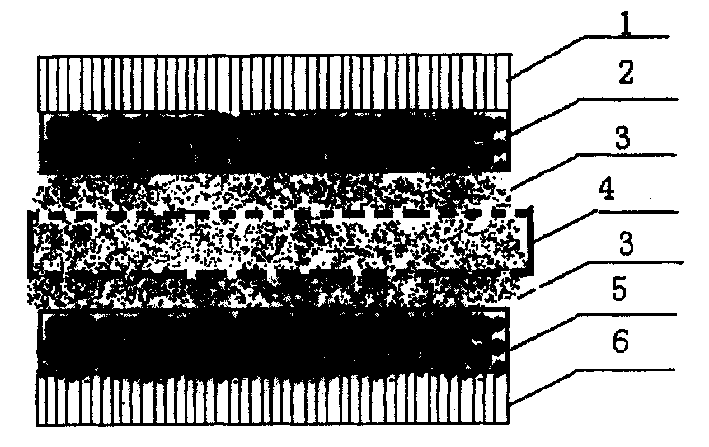

[0045] Example 1: Mix activated carbon with an average particle size of 10 microns, conductive carbon black, and polyvinylidene fluoride in a weight ratio of 80:15:5, then add an appropriate amount of nitrogen-methylpyrrolidone as a solvent, and stir for a certain period of time to obtain Uniform slurry with a certain viscosity, use a casting machine to evenly coat the mixed slurry on the nickel foam current collector, then stay in the drying oven at 85°C for 60 minutes, take it out and put it on the automatic temperature-controlled rolling mill Roll from low temperature to high temperature first, the lowest temperature is generally not less than 50°C, the setting of the highest temperature is 5°C higher than the melting point of the binder polymer, and the rolling gap is adjustable from 50 to 2000 microns . In order to prevent the electrode active material from adhering to the rollers of the rolling mill and enhance the adhesion of the carbonaceous active material to the curr...

Embodiment 2

[0048] Embodiment 2: Manufacture carbonaceous active material electrode and supercapacitor monomer with the method identical with embodiment 1. The difference is that the positive and negative current collectors 1 and 6 used in the manufactured supercapacitor monomer are both nickel foils, the cut electrode area is 100 square centimeters, the thickness is 240 microns, and the concentration of sodium sulfate is 2 mol / liter. The aqueous solution is used as the electrolyte, its rated working voltage is 1.1 volts, its Faraday capacity is 92 Faradays, its specific power density is 340 W / kg, its specific energy density is 2.3 Wh / kg, its discharge capacity remains above 97% after 10,000 charge and discharge cycles, and its electrode expansion rate is 7.2%.

Embodiment 3

[0049] Embodiment 3: Manufacture carbonaceous active material electrode and supercapacitor monomer with the method same as embodiment 1. The difference is that the positive electrode current collector 1 of the manufactured supercapacitor monomer is aluminum mesh, the negative electrode current collector 6 is copper mesh, the electrode area is 180 square centimeters, the thickness is 220 microns, and the concentration is 1 mol / liter. The propylene carbonate solution of tetraethyl tetrafluoroborate ammonium salt is used as the electrolyte, its rated operating voltage is 2.7 volts, its Faraday capacity is 89 methods, its specific power density is 320W / kg, its specific energy density is 3.6Wh / kg, and its charge and discharge cycle is 5 The thousand-time discharge capacity remains above 98%, and the electrode expansion rate is 7.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com