Rear-view mirror for vehicle

A technology for rear-view mirrors and vehicles, applied in the field of rear-view mirrors for vehicles, can solve the problems of large gap between the shell and the lens, easy deformation of the lens, etc., and achieve the effect of enhancing impact resistance and avoiding deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

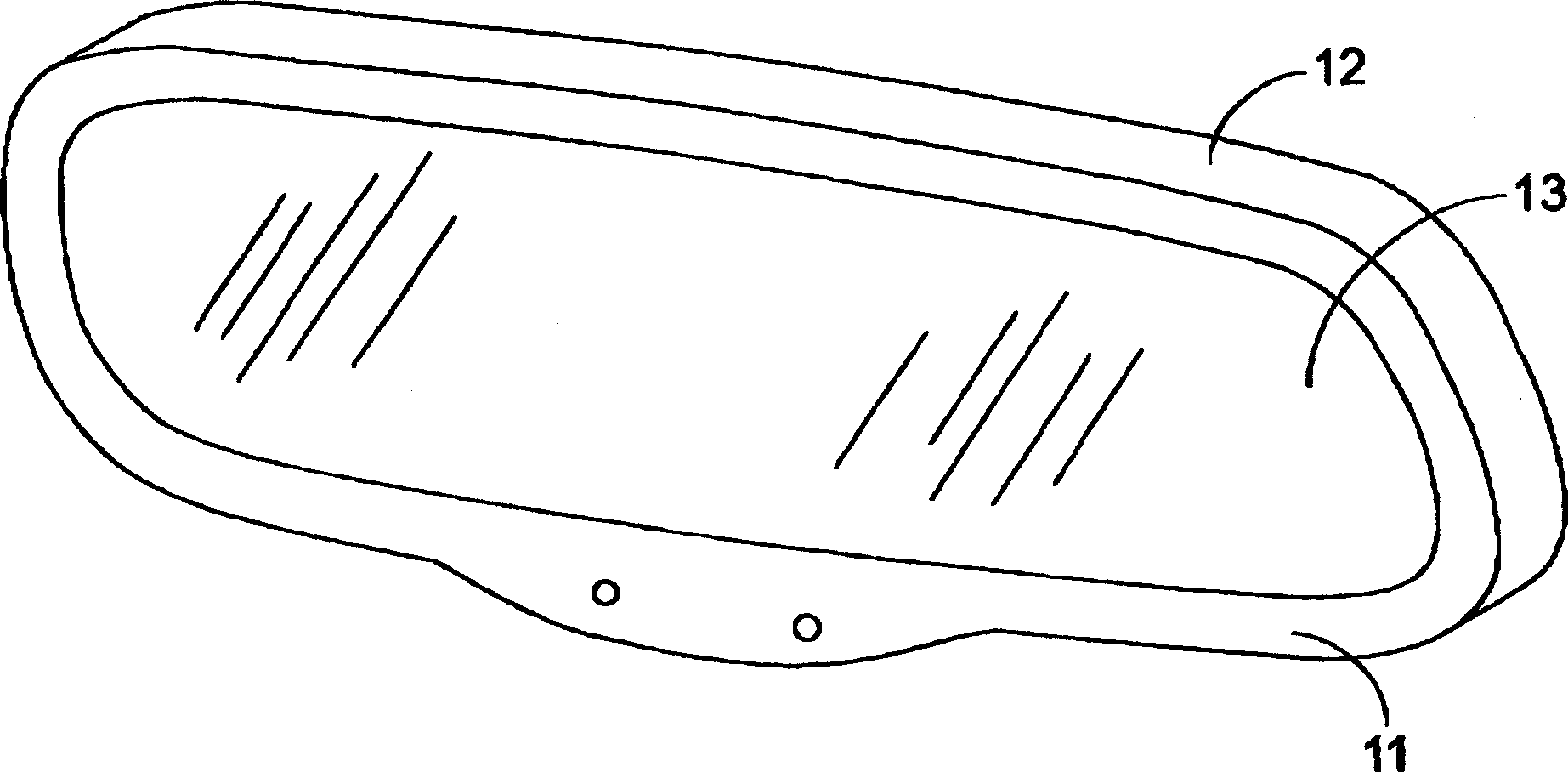

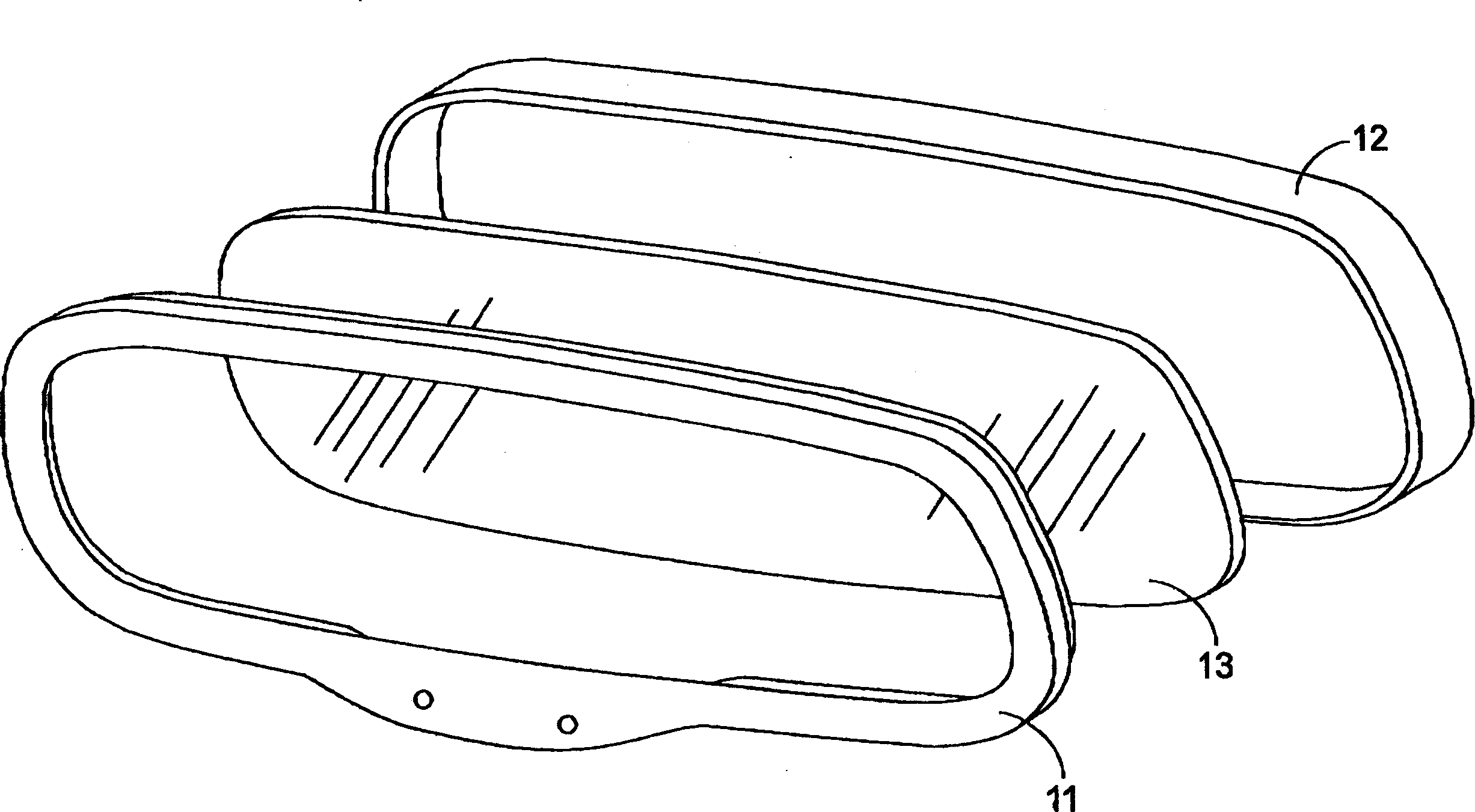

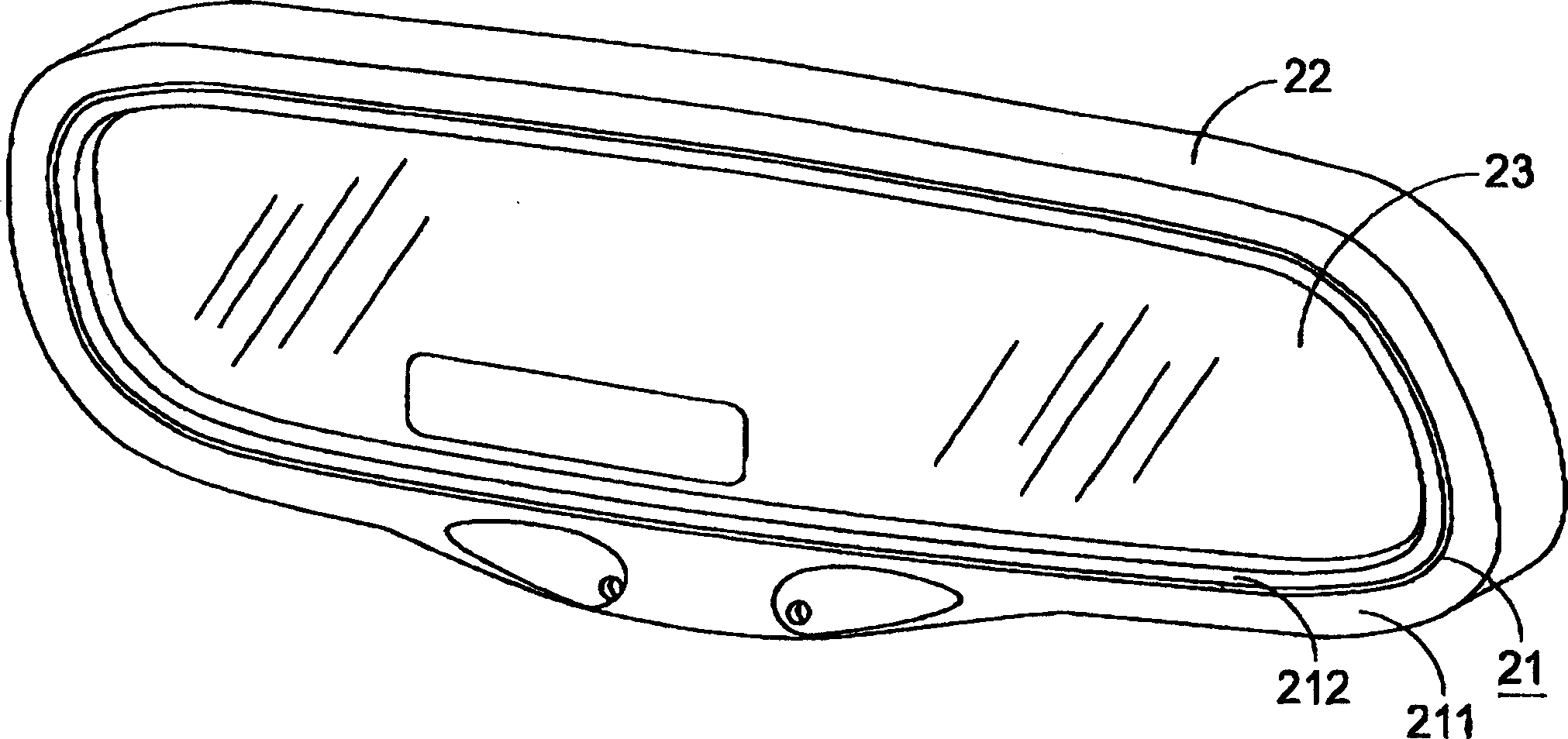

[0039] Please see Figure 2(a) and Figure 2(b). A vehicle rearview mirror of the present invention includes a front housing 21 , a rear housing 22 , and a lens 23 . When assembling, the lens 23 is put into the rear case 22 through the opening 220 , and then the front case 21 is placed on the lens 23 and combined with the rear case 22 . The combination of the front case 21 and the rear case 22 can be done by gluing, fitting, welding or any other suitable way, depending on the materials to be combined. The material of the rear shell is different according to the requirements of practicability and aesthetics, for example, it can be plastic, rubber, resin, metal material, carbon fiber or wood. Preferably, the rear shell material is made of an engineering material, such as nylon (nylon), PBT, PC, ABS, HI-PS, PP, LCP, PE or PS, and is also suitable for materials such as magnesium alloy and carbon fiber. Made. When nylon is used as the material of the rear shell, glass fibers can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com