PVDC laminated composite high-temp-resistant steamed and boiled food packaging film and its preparation method

A technology for food packaging film and high temperature resistance, which is applied in the preparation of the PVDC laminated composite high temperature resistant cooking food packaging film, PVDC laminated composite high temperature resistant cooking food packaging film field, which can solve the problem of high product cost, insufficient softness, invisible To achieve the effect of good food hygiene performance, stable chemical performance, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

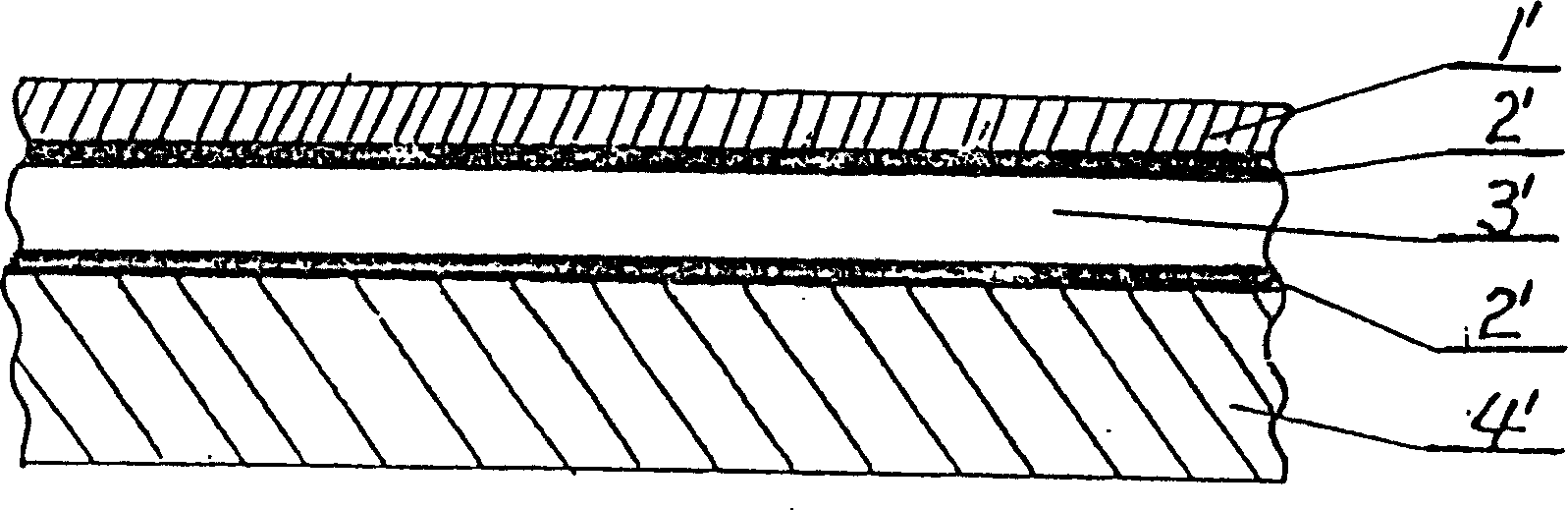

[0046] Such as figure 1 As shown, the middle layer PVDC (copolymer film of vinylidene chloride and vinyl chloride) 3' is connected to the outer layer 1' and the inner layer 4' through two-component polyurethane solvent-free adhesive 2' respectively, wherein the outer layer 1' is PET (polyester film), and the inner layer 4' is CPP (cast polypropylene film). Outer layer 1 ' also can be BOPP (biaxially oriented polypropylene film) or BOPA (biaxially oriented nylon film) simultaneously.

[0047] The cross-sectional structure of the composite membrane in this embodiment is: PET / adh / PVDC / adh / CPP, where: adh represents a two-component polyurethane solvent-free adhesive. The total thickness of the composite film is: 86μm

[0048] The thickness of each layer is: PET is biaxially stretched polyester film, the thickness is: 12μm;

[0049] adh is a two-component polyurethane solvent-free adhesive layer with a thickness of 2 μm;

[0050] PVDC is a biaxially stre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| barrier rate | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com