Variable capacity rotary compressor

A rotary compressor and capacity technology, applied in rotary piston machinery, rotary piston pumps, rotary piston/oscillating piston pump combinations, etc., can solve sudden changes in operating conditions, shortened life of drive motors and compression devices, Problems such as the inability to effectively realize the oil supply of the compression device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Non-limiting embodiments of the invention will be described below with reference to the accompanying drawings.

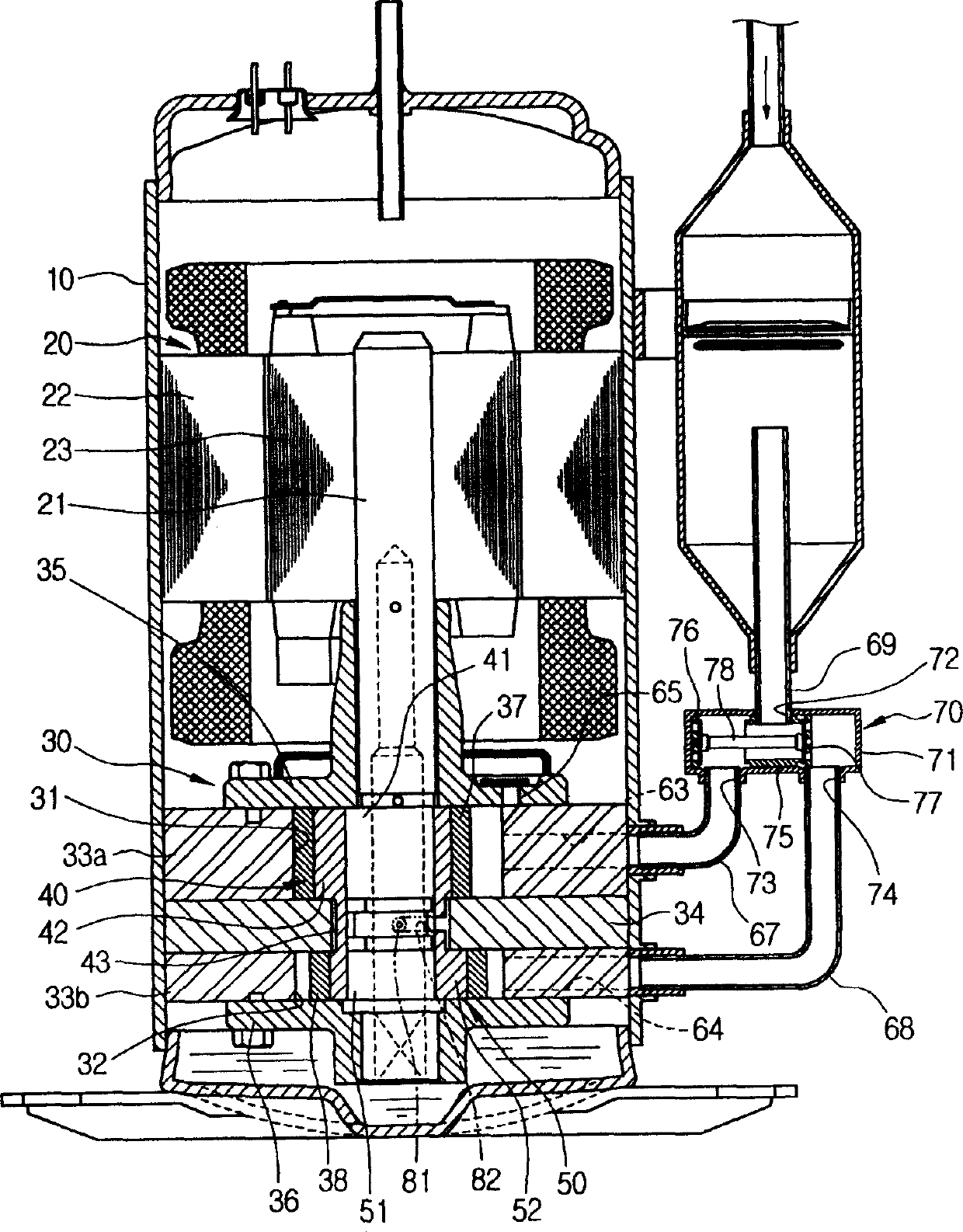

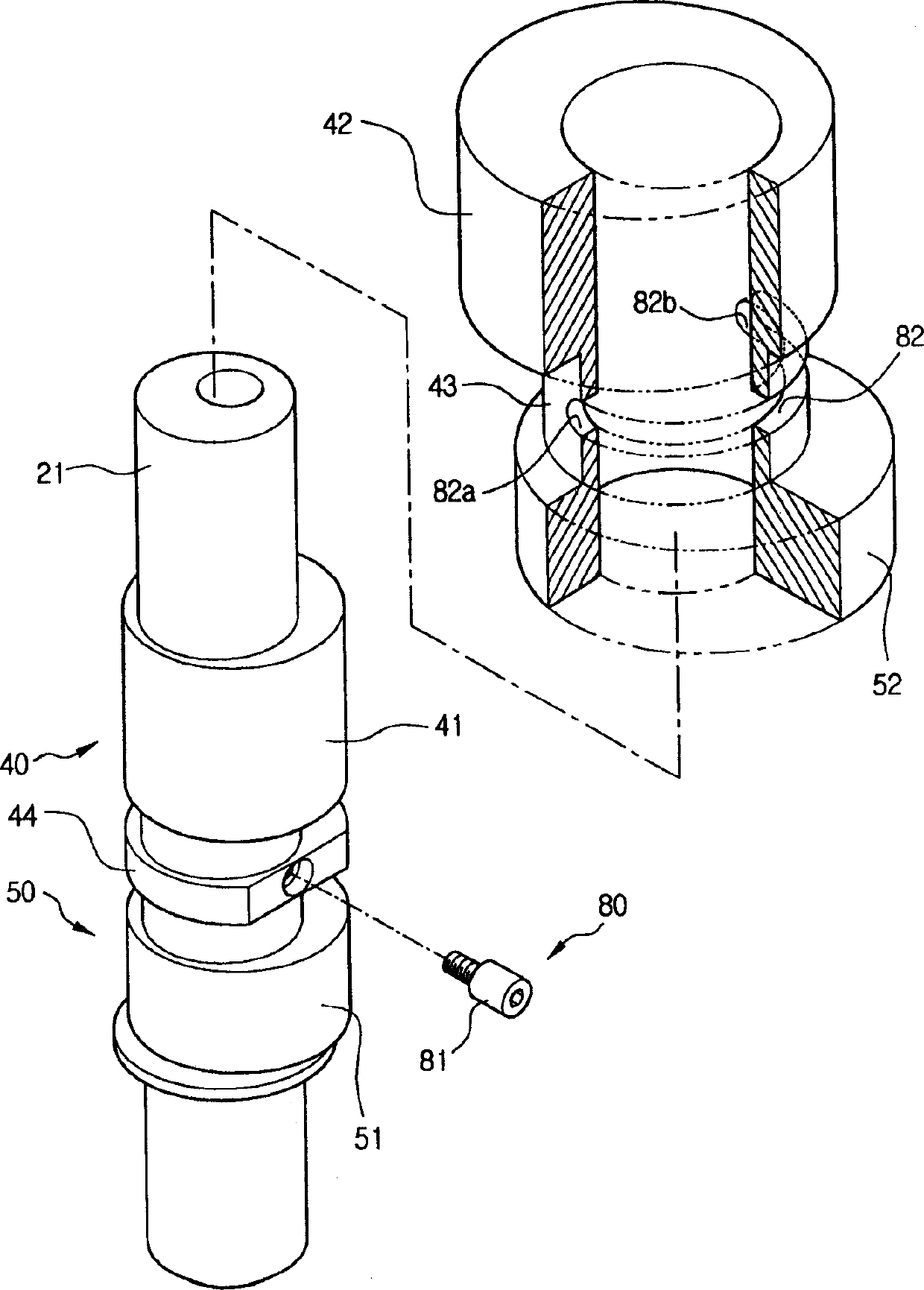

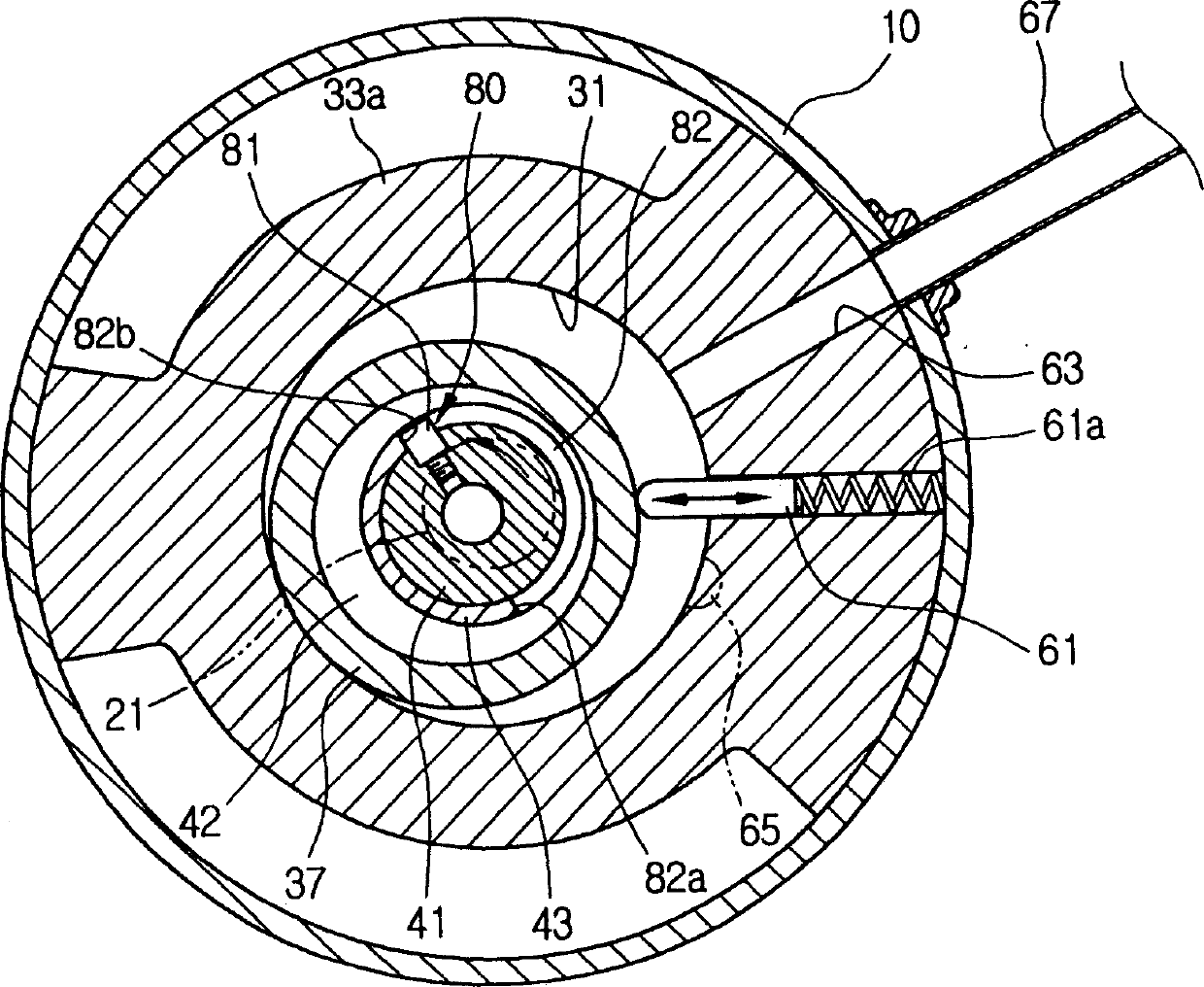

[0025] Referring to Fig. 1, a variable capacity rotary compressor according to an exemplary embodiment of the present invention includes: a sealed casing 10; a drive motor 20 installed on the top of the casing 10 in the casing 10 and adapted to generate rotational force; And a compression device 30 installed in the lower part of the casing 10 in the casing 10 and connected to the driving motor 20 through the rotating shaft 21 .

[0026] The driving motor 20 includes: a cylindrical stator 22 fixedly installed on the inner surface of the casing 10; and a rotor 23 rotatably installed in the stator 22 and connected to the rotating shaft 21 at the center thereof. Drive motor 20 may comprise a variable speed motor designed to rotate forward and direction and to control the speed of rotation thereof. For such a variable speed motor, an inverter motor or a BLDC moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com