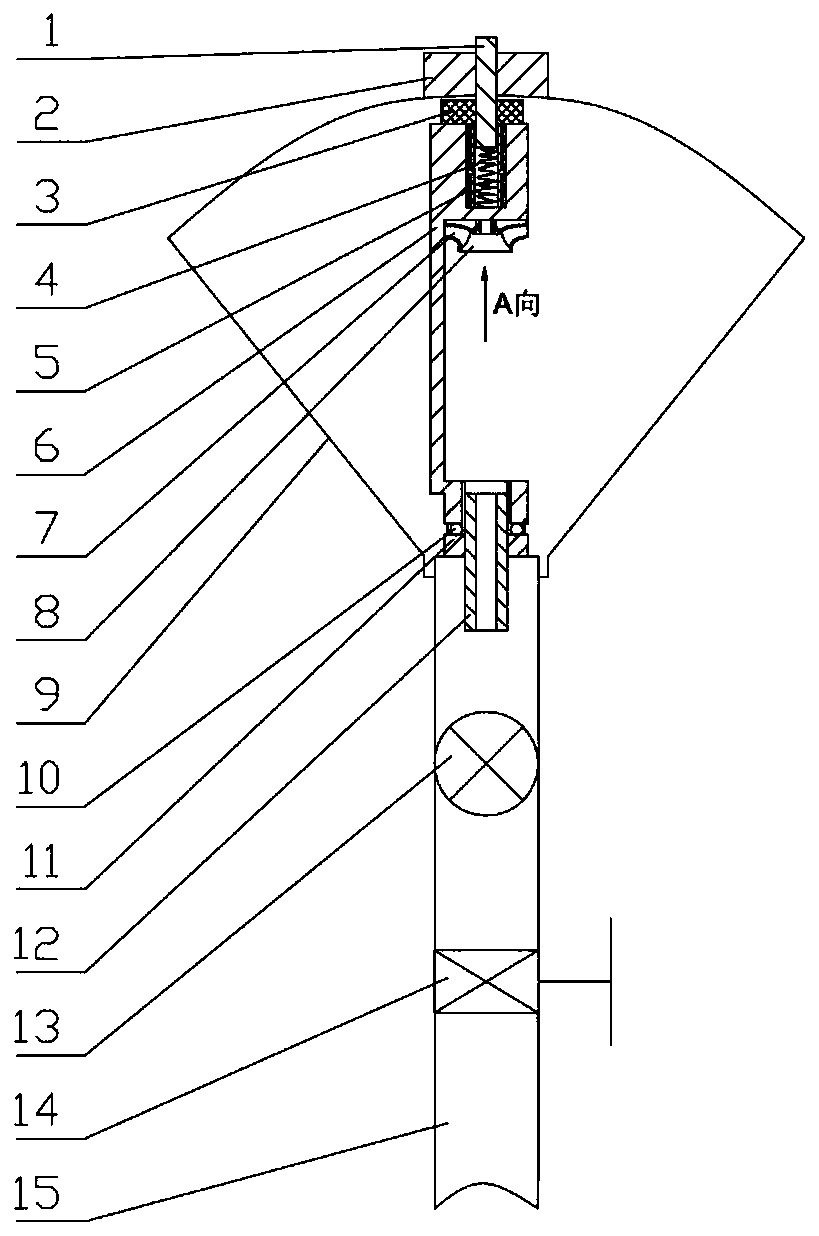

Impeller-driven rotary nozzle and rotation speed adjusting method thereof

A technology of rotating nozzles and rotating speeds, which is applied to botanical equipment and methods, spraying devices with movable outlets, spraying devices, etc., and can solve the problems of complex structure of rotating spraying elements, difficult adjustment of hydraulic performance parameters, and insufficient stability of work. , to achieve the effect of improving spraying uniformity, convenient and reliable adjustment, and realizing optimal settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

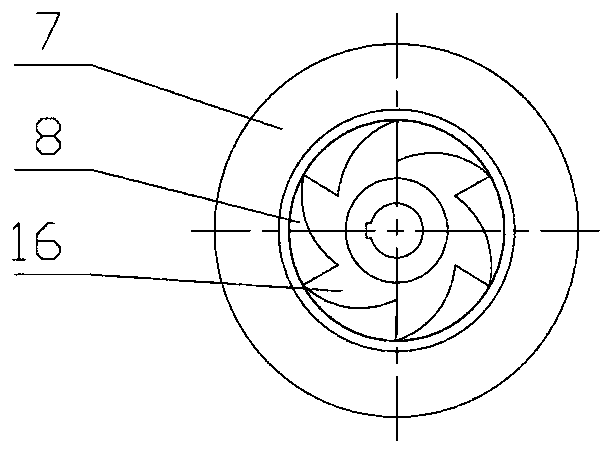

[0033] Embodiment 1: The structural form of impeller 8 is the semi-open impeller shape that comprises blade and rear cover plate, and damping device 4 adopts spring damping, and when the rotating speed of test record is 10 seconds per circle, spraying uniformity coefficient is 88%, spraying The shooting range is 7.4 meters, and the median particle size of sprayed water droplets is 0.7 mm. After adjusting the damping coefficient of the damping device 4, the rotating speed can be changed to 60 seconds per revolution, the spraying uniformity coefficient is 85%, the spraying range is 7.9 meters, and the median diameter of sprayed water droplets is 0.9 mm.

Embodiment 2

[0034] Embodiment 2: damping device 4 adopts spring damping, and the structural form of impeller 8 is the closed impeller shape that comprises blade, front and rear cover plate, and rotation speed is 20 seconds per circle, and spraying uniformity coefficient is 75%, and spraying range is 9.8 meters, the median particle size of the sprayed water droplets is 1.2 mm. Increased spray range of impeller-driven performance-adjustable rotary elements.

Embodiment 3

[0035]Embodiment 3: The damping device 4 adopts spring damping, and the structural form of the impeller 8 is a semi-open impeller shape including blades and a rear cover plate, the rotation speed is 20 seconds per circle, the spraying uniformity coefficient is 87%, and the spraying range is 7.6 m, the median diameter of the sprayed water droplets is 0.8 mm. Improved spray uniformity from the impeller drive performance adjustable rotary element.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com