Positive yarn feeding system of circular knitting machine and control method thereof

A technology of active yarn feeding and circular weft machine, applied in the direction of weft knitting, textile and paper making, knitting, etc., can solve the problems of weaving jacquard fabrics, low control precision and troublesome operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be pointed out that the scope of protection of the present invention is not limited to the following embodiments. Retouching should be regarded as the scope of protection of the present invention.

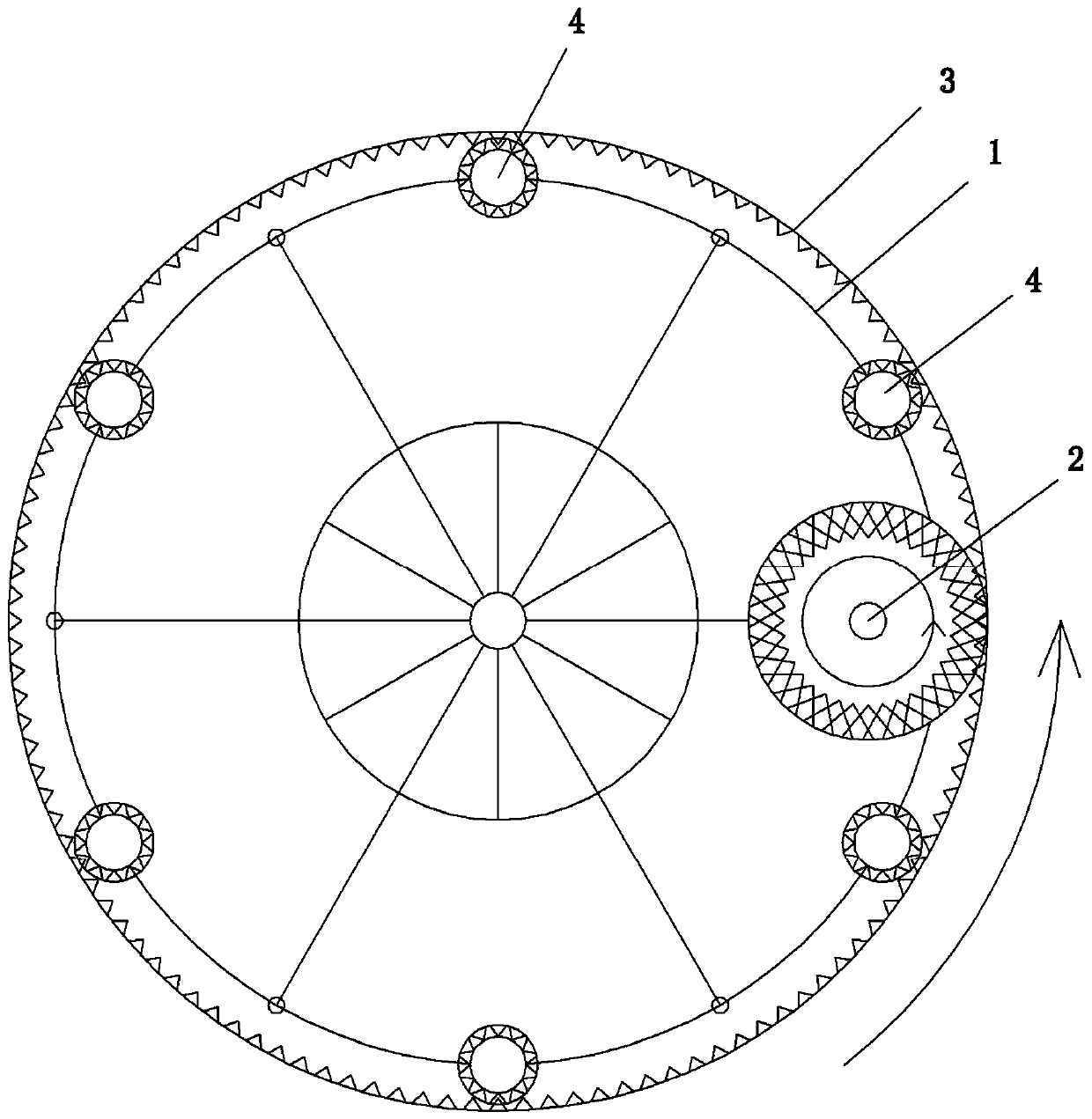

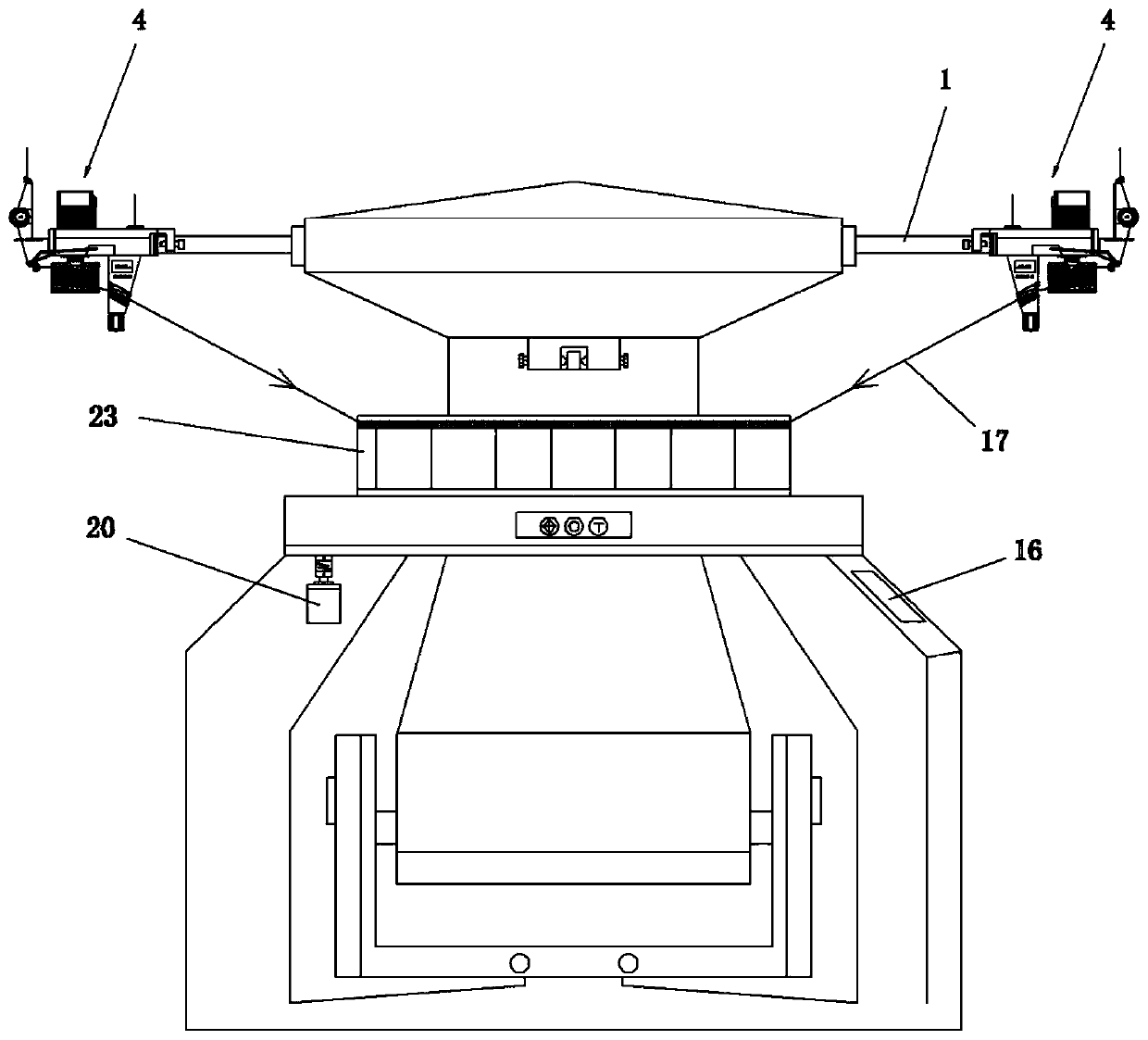

[0028] Such as image 3 , Figure 4 , Figure 6 As shown, the active yarn feeding system of the circular weft machine of the present invention includes a yarn feeding device, a host computer 16 and an encoder 20 . The encoder 20 is used to measure the rotational speed of the dial 23 of the circular weft machine and convert it into a synchronous pulse signal and send it to the host computer 16 . The yarn feeding device includes a horizontally arranged fixed ring 1 and a plurality of yarn feeders 4 uniformly installed on the fixed ring 1 , and each yarn feeder 4 is connected to a host computer 16 with signals.

[0029] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com