Engine power storage conversion energy-saving device

An energy-saving device and engine technology, applied in the field of variable speed machinery, can solve problems such as waste of fuel, effective engine power and fuel waste, environmental pollution, etc., and achieve the effect of increasing the speed of the car, reducing fuel consumption, and improving power performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

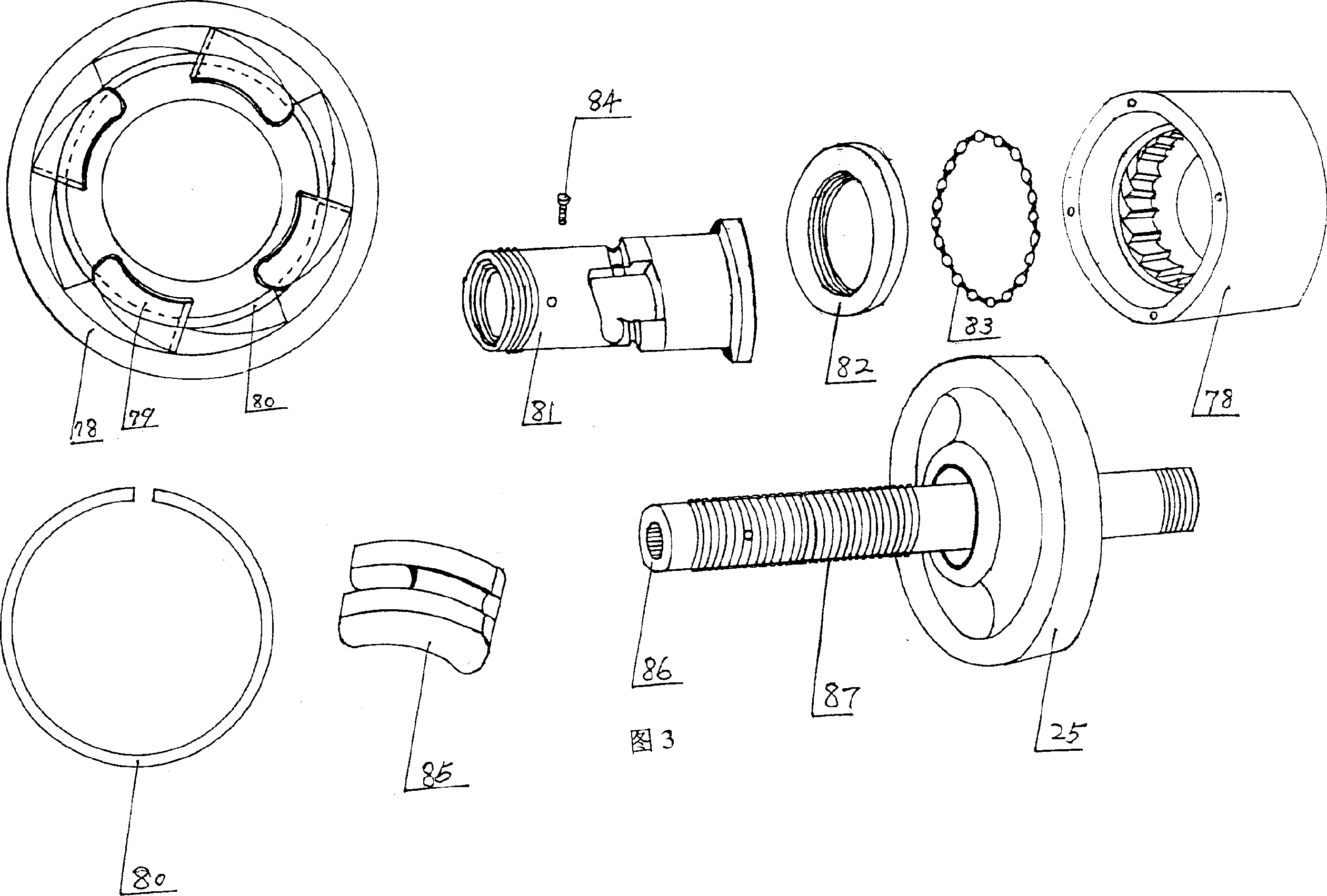

[0020] All parts in the present invention can be processed by existing processing methods. After processing, it can be assembled with reference to the attached drawings.

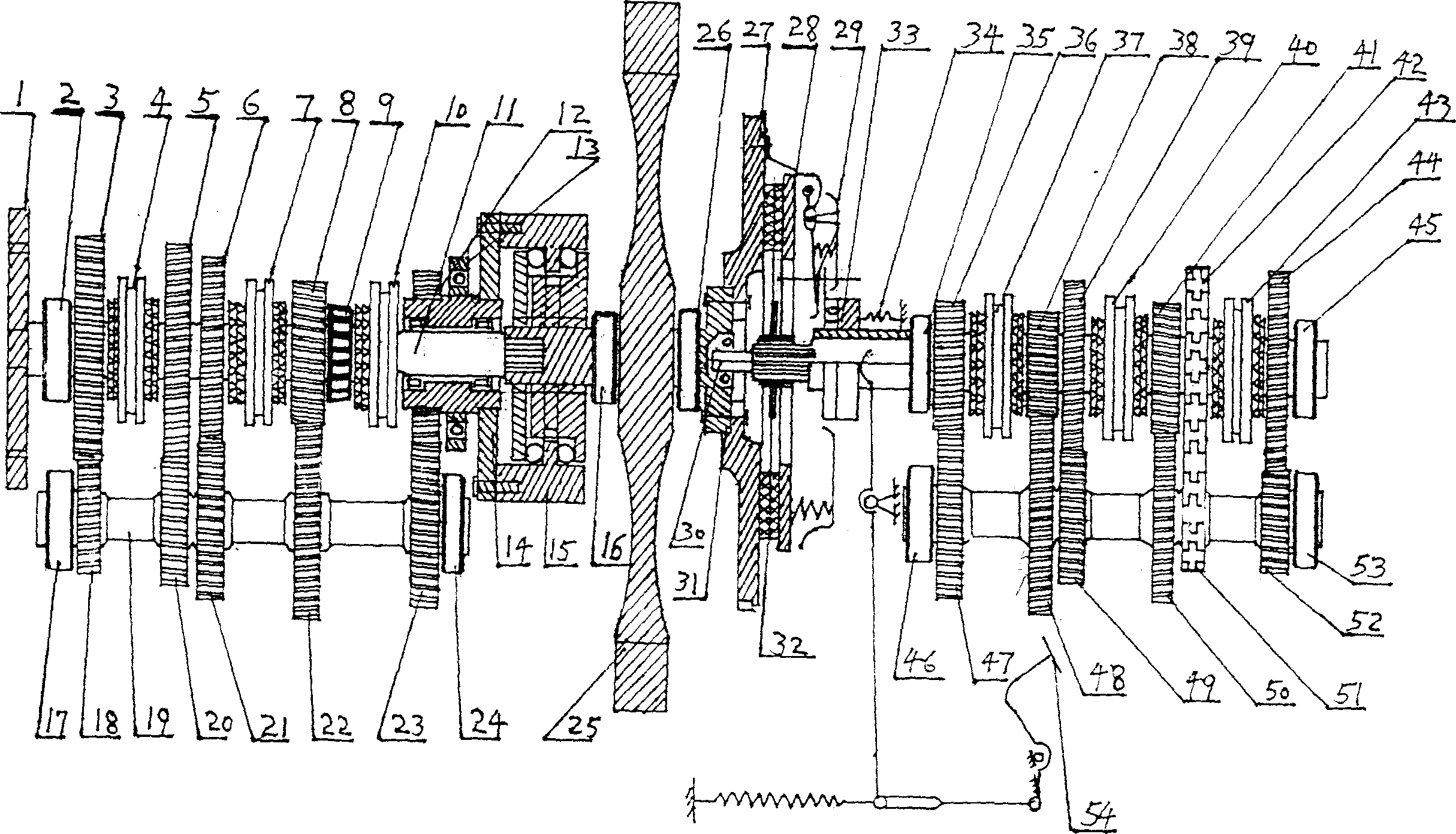

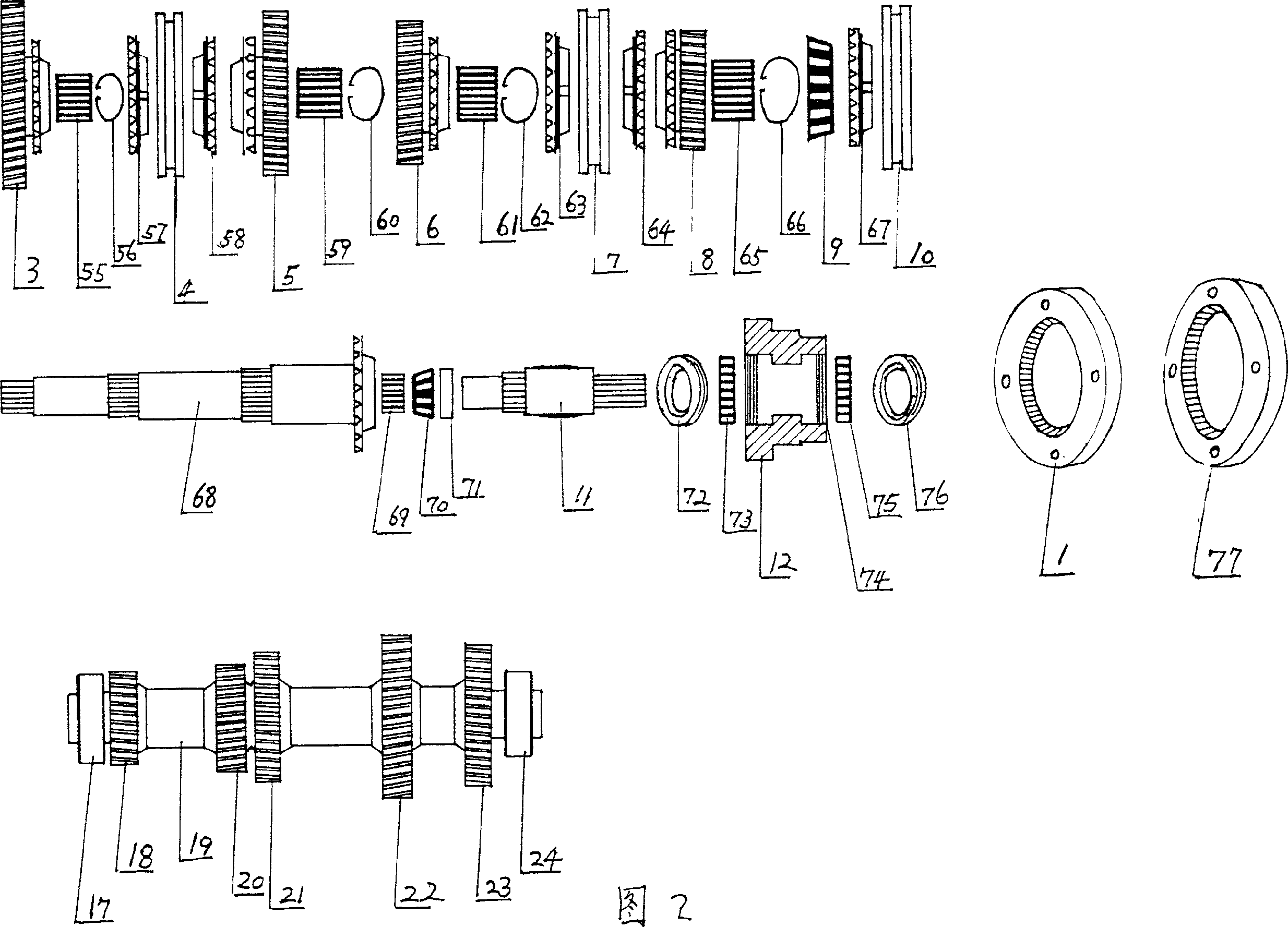

[0021] figure 1 Among them, 1 is the connecting disc fixed with the flywheel on the crankshaft of the engine; 2 is the fixed bearing of the power input shaft; 3 is the fifth gear driving gear; 4 is the synchronizer between the fifth gear and the third gear; 5 is the third gear driving gear; 6 7 is the synchronizer of the first gear and the second gear; 8 is the first gear driving gear; 9 is the thrust bearing of the input shaft; 10 is the synchronizer of the fourth gear (direct transmission gear); 11 is the second shaft Power output shaft; the fixed gear 12 on the outer shaft sleeve is a constant meshing transmission gear 23 with the power output, and the radius of the two gears is the same; 19 is an intermediate shaft; 17 and 24 are fixed bearings for the intermediate shaft; 18 is a driven gear for first g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com