Powder metallurgy internal hilical gear, and its manufacturing method and die using same method

A technology of internal helical gear and powder metallurgy, which is applied in the field of powder metallurgy internal helical gear and its manufacturing and implementation of the mold, can solve the problems of increasing raw material loss, difficulty in withdrawing the mandrel, and high manufacturing cost, so as to save raw materials and manufacture The effect of low cost and compact mold structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

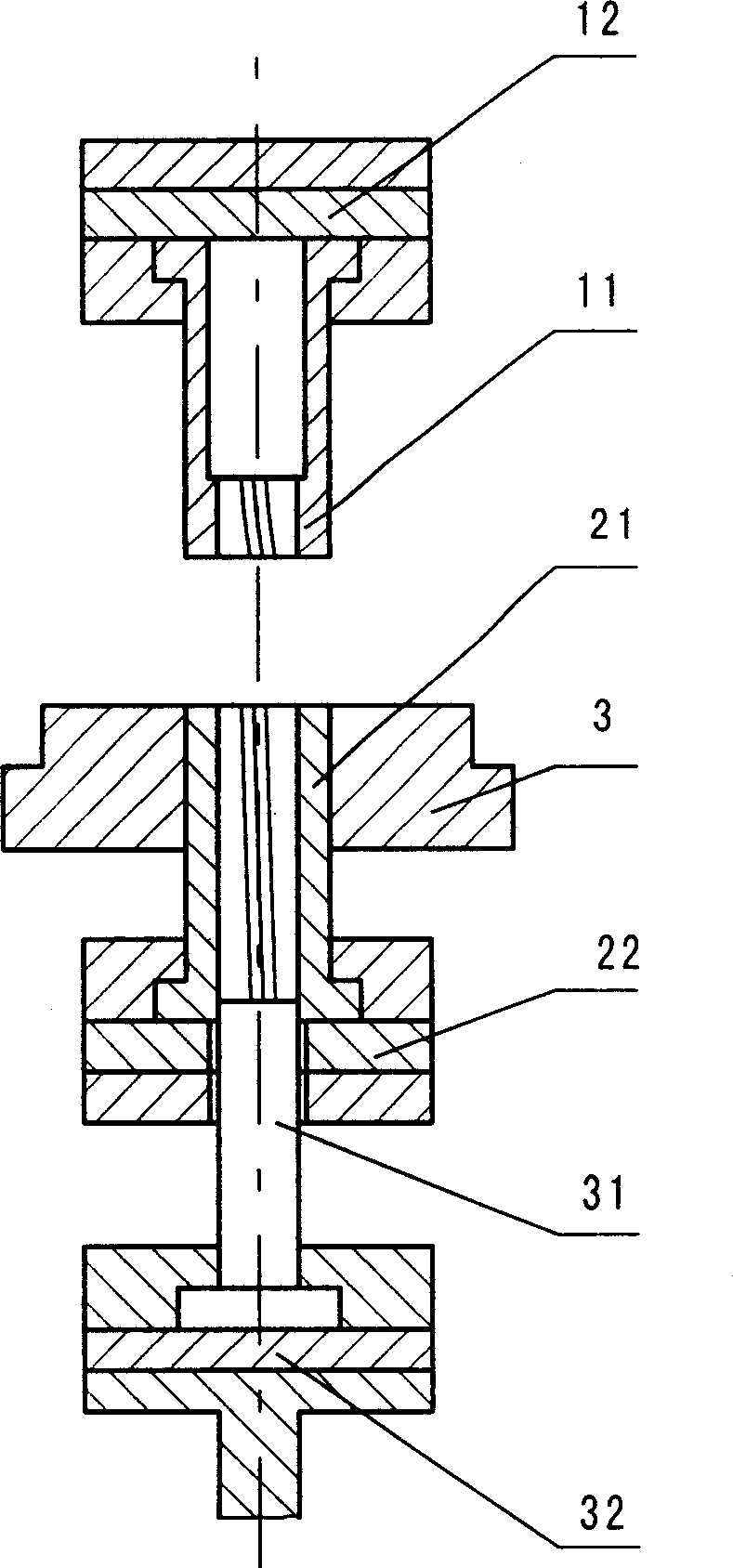

[0017] Attached below Figure 1-2 Embodiments of the present invention will be further described in detail.

[0018] The sintering treatment is not to completely melt the material powder into an alloy. The sintering treatment is to heat-treat the formed body of the metal or alloy powder under pressure at a temperature below the melting point of the main element, and use the solid solution phenomenon produced by the combination of powders to sinter. into.

[0019] The technical scheme of the powder metallurgy internal helical gear of the present invention is that, by weight percentage, the composition of the above-mentioned internal helical gear contains alloy elements Cu 1-3%, Ni 1-3%, Mo 0.1-1%, and the rest is Fe and unavoidable ingredients.

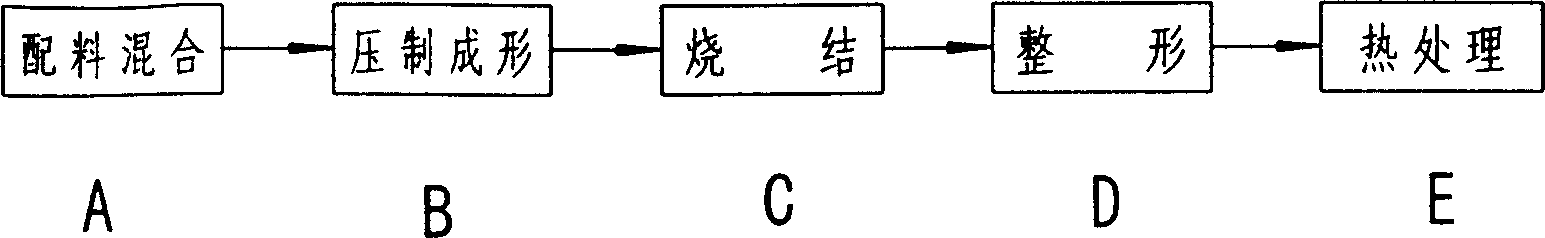

[0020] figure 1 As shown, in the batching and mixing process A, the raw material powder composed according to the proportion of pre-alloyed steel powder containing Cu 1-3%, Ni 1-3%, Mo 0.1-1%, and the rest is Fe The mixture is a bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com