Spectral analysis method for online detecting size distribution of inclusions in steel

A particle size distribution and spectral analysis technology, applied in the field of metal material detection, can solve problems such as low precision and unreasonable analysis methods, and achieve the effects of improving product qualification rate, realizing online quality control, and fast analysis speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiments of the present invention will be described below with reference to the accompanying drawings. Here, only the Al 2 O 3 Take the inclusion as an example.

[0035] Use as Figure 4 In the device shown, the spectroscopic analysis method for on-line detection of the particle size distribution of inclusions in steel consists of the following steps:

[0036] 1) In the inert gas environment in the light-emitting station (2), a pre-discharge of 200-700 pulses is performed between the steel sample and the counter electrode, and then a formal spark discharge of 1500-2000 pulses is performed;

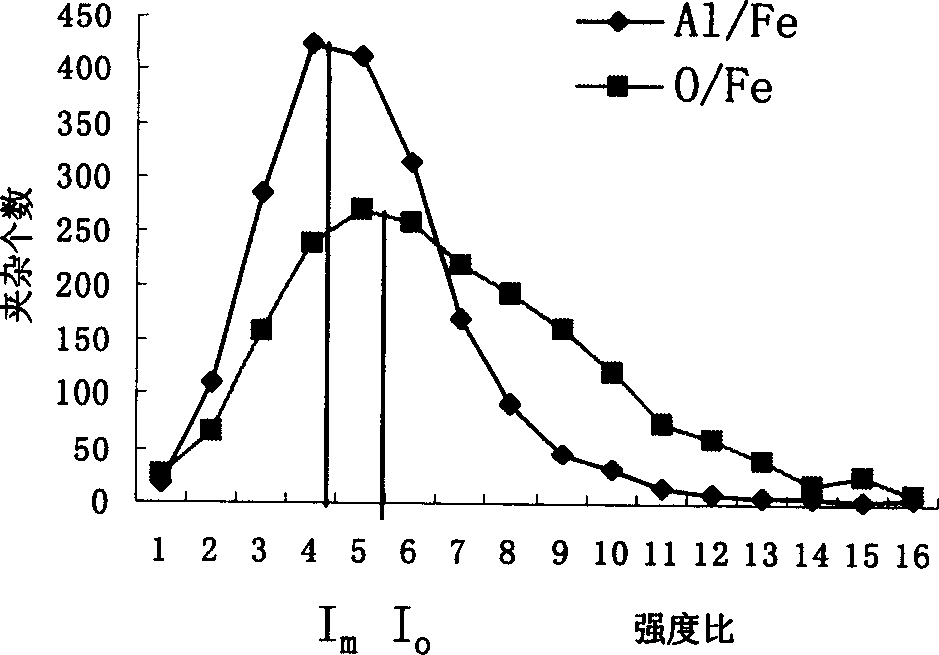

[0037] 2) The luminescence of each spark discharge is split in the spectroscopic device (1) to obtain the spectral lines of each element, and the critical value of the metal element aluminum inclusion intensity and the critical value of the oxygen intensity of the inclusion monitoring element are obtained in the calculation device (5). Such as figure 1 , Figure 2 and im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com