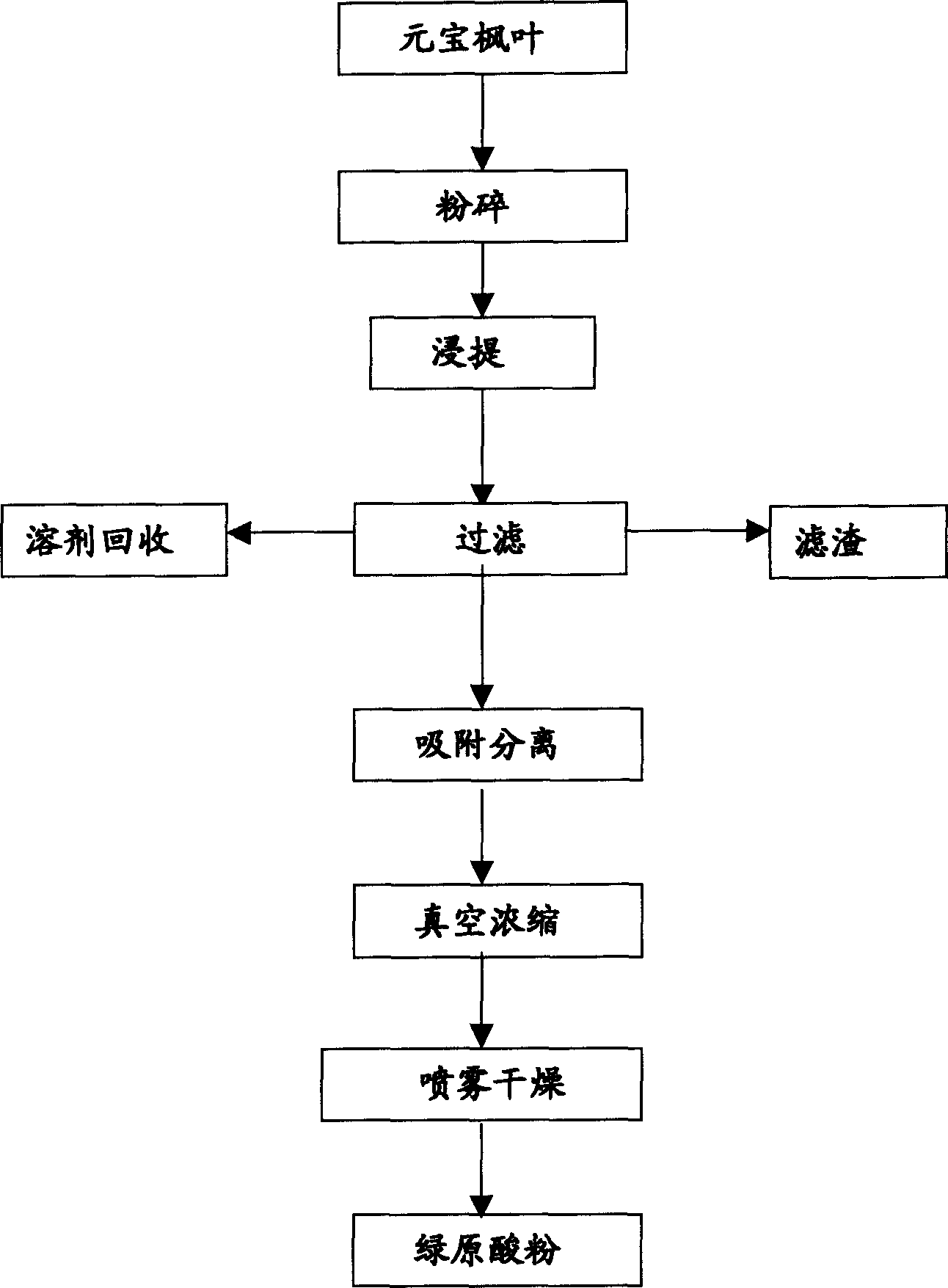

Technology for extracting chlorogenic acid from shoe-shaped maple leaves

A process method and technology of chlorogenic acid, applied in chemical instruments and methods, separation/purification of carboxylate, preparation of carboxylate, etc., can solve the problems of low product content and high extraction cost, and achieve good effect and heat The effect of short time and high solid solution leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Raw materials: The research results of the dynamic change of chlorogenic acid content in maple leaves of Yuanbao with seasons show that the content of chlorogenic acid in maple leaves of Yuanbao in Shaanxi Guanzhong area is the highest from June to August, and the chlorogenic acid in leaves decreases with the growth of tree age The tendency is that young trees are significantly higher than old trees, especially the chlorogenic acid content in the leaves of 1-year-old seedlings is 6.99%; therefore, harvesting the leaves of 1-year-old Yuanbao Maple seedlings between June and August can obtain the best preparation method for chlorogenic acid. raw material.

[0025] 2. Crush: Crush 1000kg of maple ingots into 8-10 meshes.

[0026] 3. Extraction:

[0027] Chlorogenic acid is a phenylpropanoid derivative, which is lively in nature and easy to oxidize and decompose. When helping to extract, the temperature, time and pH value during extraction should be controlled as much a...

Embodiment 2

[0035] Yuanbao Maple Leaf 1000g, crushed to 8-10 mesh, placed in a 100-liter circulating ultrasonic extraction device to extract chlorogenic acid, the organic solution in the circulating ultrasonic extraction device is 60% acetone, because chlorogenic acid is a phenylpropanoid derivative , the nature is active, easy to oxidize and decompose, so the extraction temperature should be controlled at 40°C, the extraction time should be controlled at 30 minutes, and the pH value should be controlled at 5-6. Controlled at 4-5, the flow rate of adsorption liquid is 8-10ml / s. The flow rate of the eluent is 5-6ml / s; the chlorogenic acid in the resin is dissolved by ethanol to obtain the chlorogenic acid eluate, and then it is concentrated in an external circulation under reduced pressure, the temperature is controlled at 50°C, and the heating time is controlled for 40 minutes , to get 40% of the finished dry powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com