Treating method suitable for presumption of recycling pure water into circulating water system

A technology of circulating water system and treatment method, which is applied in the field of scaling and microbial reproduction, and inhibits the corrosion field after assuming that the purified water is reused in the circulating water system, and can solve the difficult control and aggravation of microbial reproduction and biological slime breeding, heat exchangers Corrosion scaling and other problems, to achieve the effect of easy industrial implementation, corrosion inhibition, low treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] This example is a corrosion test on a rotating coupon, which is carried out with reference to HG / T2159-91.

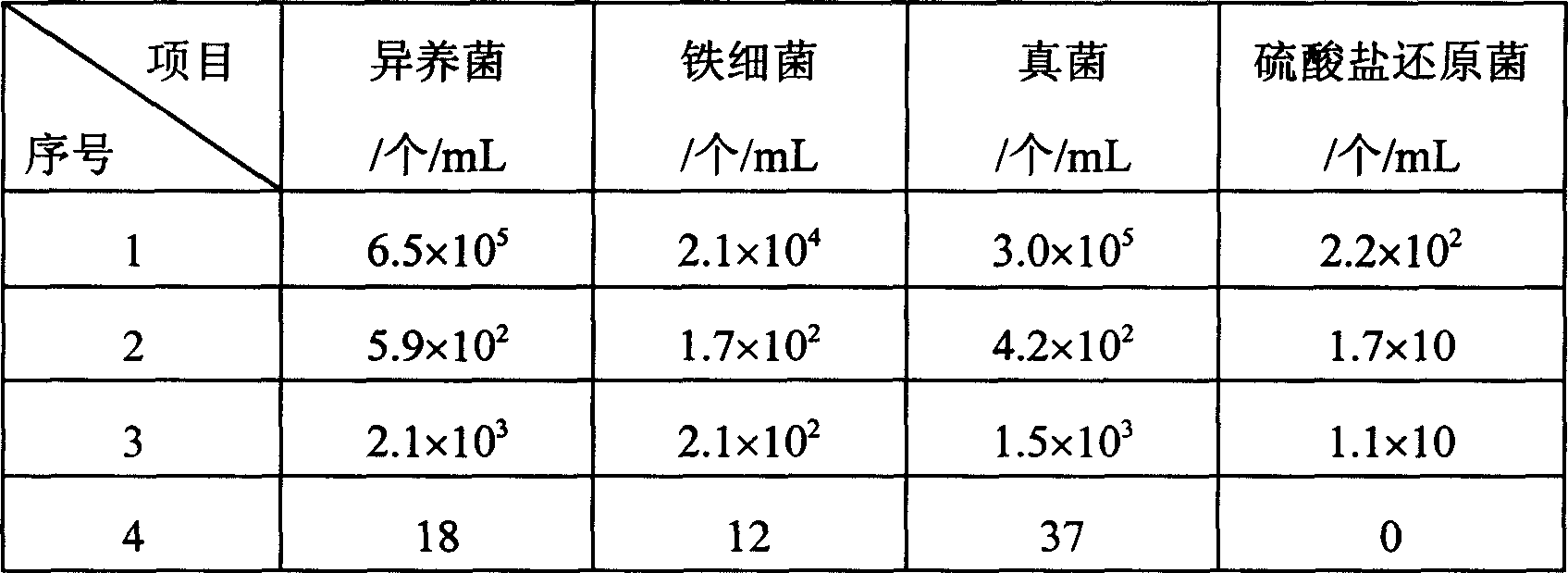

[0016] Test water quality: The test water is the on-site assumed clean water of a certain oil refinery after oil separation and settlement. The main water quality data are shown in Table 1.

[0017] project

[0018] Add different concentrations of NaHCO to the test water 3 , adjust the pH value to 8.0, then add 5mg / L hydroxyethylidene diphosphonic acid, 5mg / L hydroxyphosphine carboxylic acid, 5mg / L binary copolymer of acrylic acid and AMPS, 5mg / L zinc chloride, and rotate the plate The corrosion rate of the corrosion rate is 0.026mm / a, and the corrosion rate of the rotating coupon without the above-mentioned reagent is 1.32mm / a.

Embodiment 2

[0020] This example is a corrosion test on a rotating coupon, which is carried out with reference to HG / T2159-91.

[0021] Test water quality with embodiment 1.

[0022] Add different concentrations of NaHCO to the test water 3 , adjust the pH value to 7.5, then add 5 mg / L hydroxyethylidene diphosphonic acid, 8 mg / L sodium molybdate, 5 mg / L acrylic acid and 2-acrylamide-2-methylpropyl sulfonic acid binary copolymer , 5mg / L zinc chloride, the corrosion rate of the rotating coupon is 0.031mm / a, and the corrosion rate of the rotating coupon without the above-mentioned agents is 1.32mm / a.

Embodiment 3

[0024] This example is a corrosion test on a rotating coupon, which is carried out with reference to HG / T2159-91.

[0025] Test water quality with embodiment 1.

[0026] Add different concentrations of NaHCO to the test water 3 , adjust the pH value to 10.5, then add 5mg / L 2-phosphino-1,2,4-tricarboxylic acid-butane, 10mg / L sodium hexametaphosphate, 8mg / L acrylic acid and 2-acrylamide-2 - The binary copolymer of methyl propyl sulfonic acid, 5mg / L zinc chloride, the corrosion rate of the rotary coupon is 0.021mm / a, and the corrosion rate of the rotary coupon without the above-mentioned agent is 1.32mm / a.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com