Waterproof shoe structure with folded interior upper

A technology for waterproof shoes and inner uppers, which can be used in shoe uppers, footwear, boot legs, etc., and can solve problems such as functional layer cracks and no longer waterproof.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

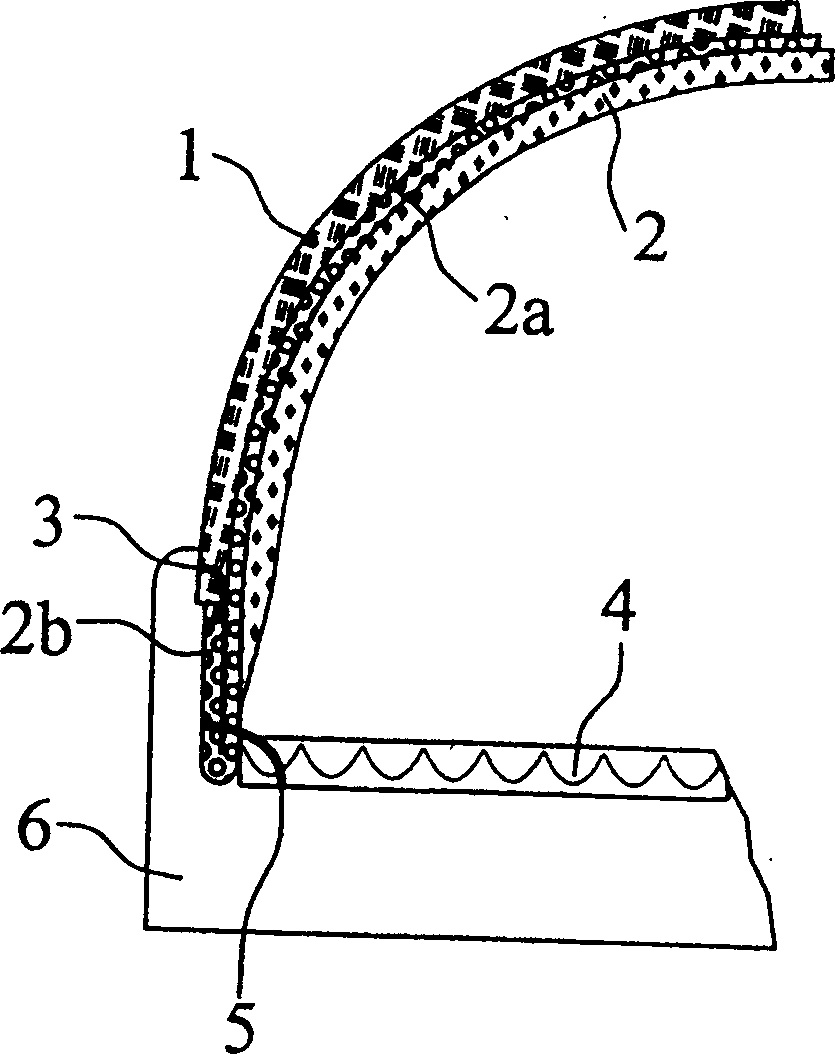

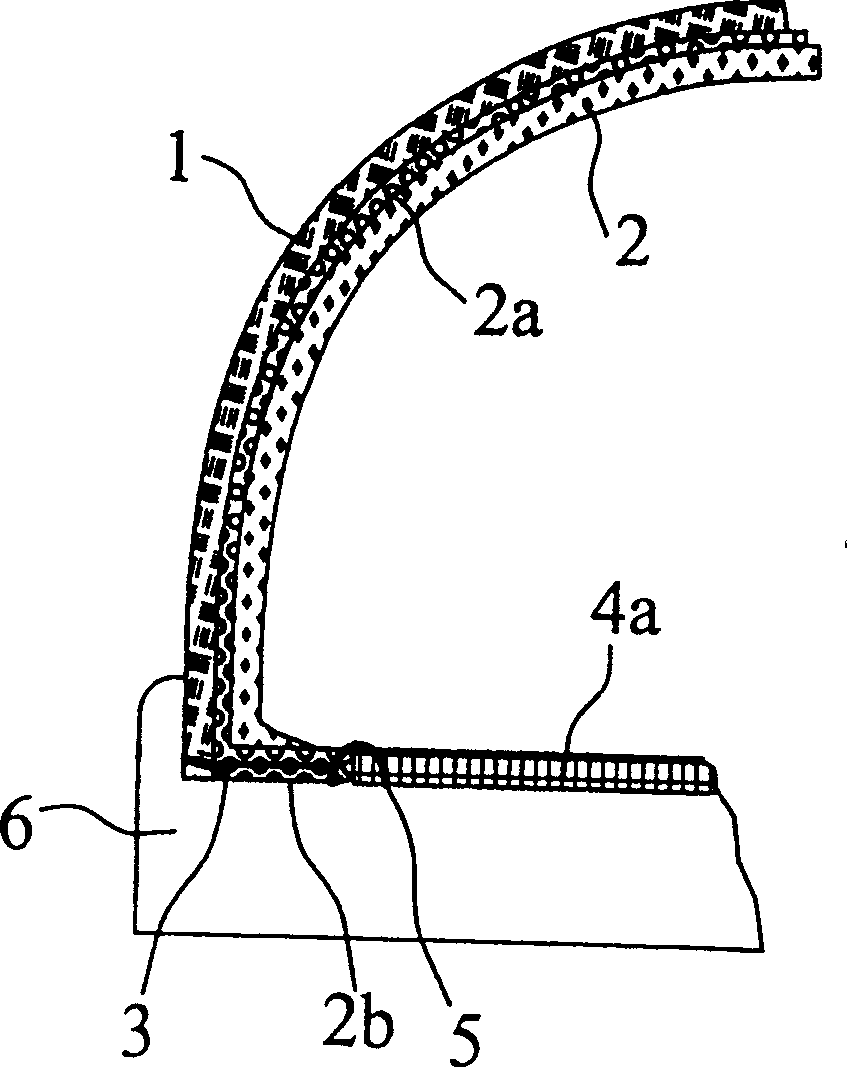

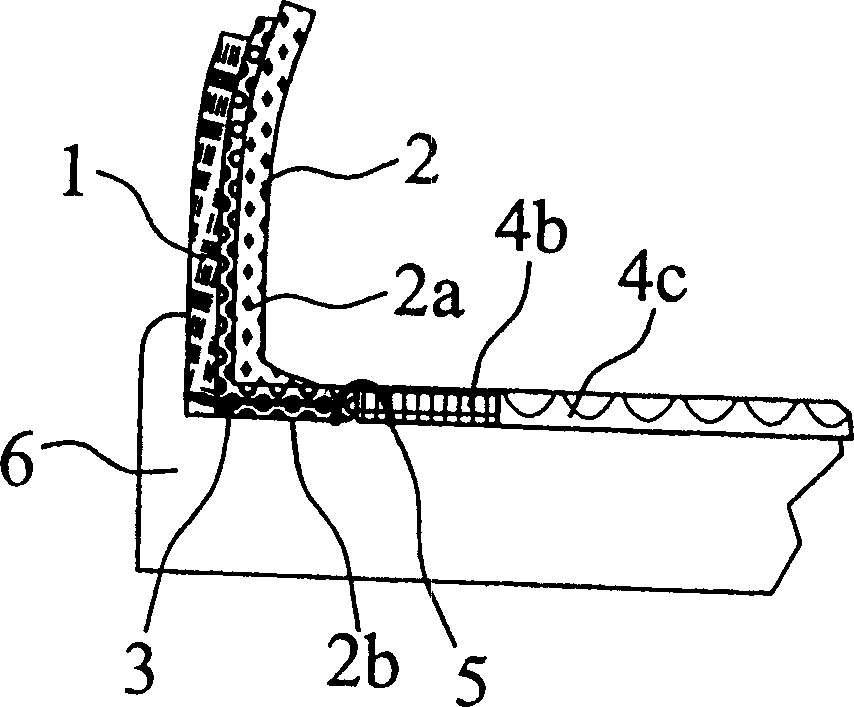

[0021] As can be seen from the embodiments in the accompanying drawings, the shoe structure of the present invention has an outer upper 1; an inner upper comprising at least waterproof and water vapor permeable functional layers 2a, 2b and a lining 2; an insole 4; and an outer shoe Bottom 6. The end regions of the inner side extending beyond the outer part 1 are folded outwards, so that the functional layer located in the entire end region is folded in half and has a lower edge produced by the folding. In the end region of the inner upper, the inner upper is not lined as far as the shoe interior, so that in this region the functional layer 2 a adjoins the outsole and is thus connected to the outer sole to a wider extent. By removing the lining, a wide range of, in particular waterproof, bonds can be produced between the functional layer and the material of the outsole.

[0022] The inner side can also comprise another fabric layer (not shown in the figure for clarity) which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com