Ginding disc type high-speed extruder

A high-speed extrusion, grinding disc technology, applied in the mechanical field of polymer melt processing, can solve the problems of slow melting rate and low productivity, and achieve the effects of fast extrusion rate, rapid melting and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

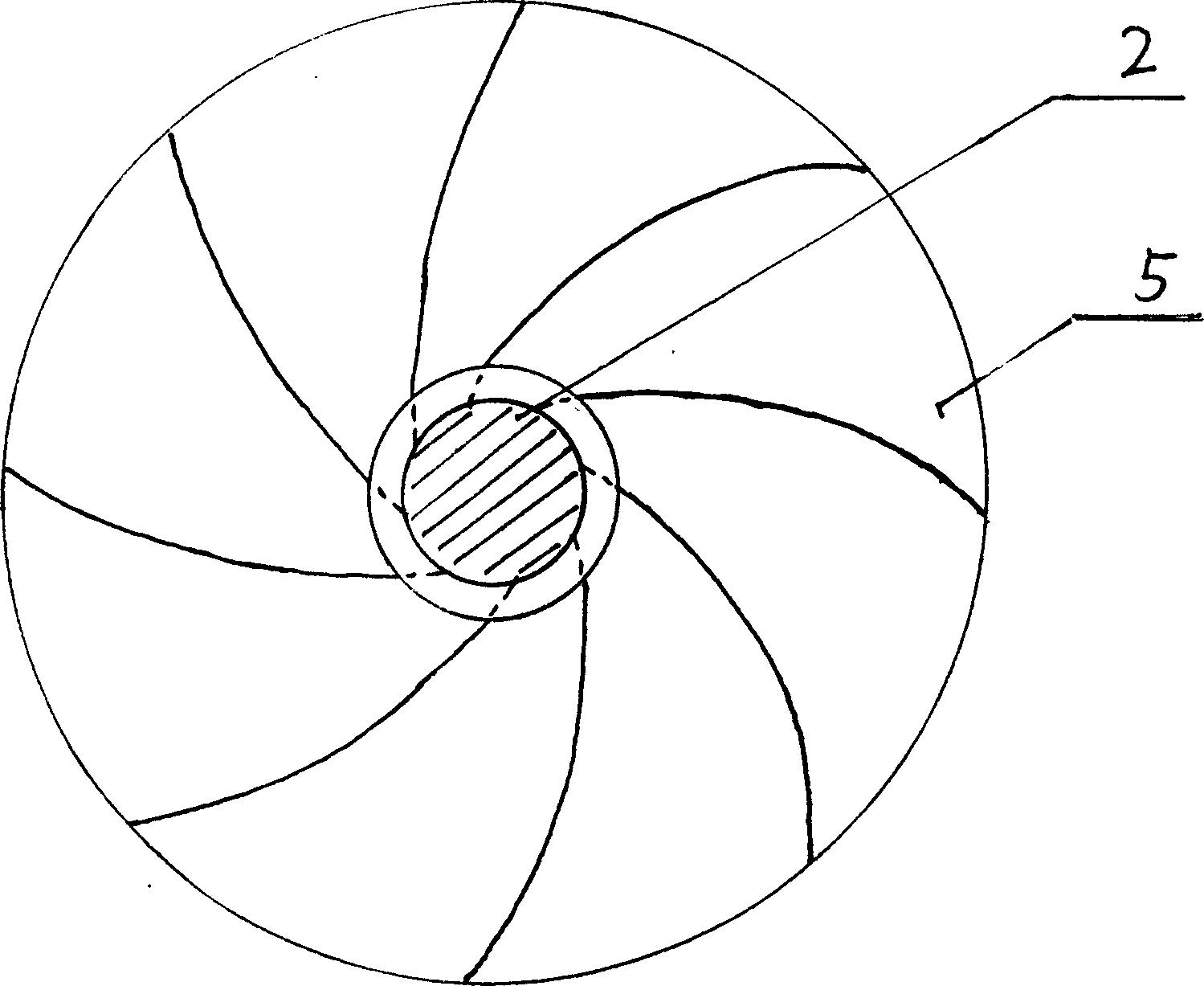

[0033] As shown in Figure 1, the screw rod (2), rotating disk (5), and rotating shaft (11) are an integral part, supported and fixed on the frame (8) by thrust bearings (9) and ordinary bearings (10) . Fixed disk (4), screw barrel (3) are an integral part, installed on the rotating disk (5), screw rod (2) passes through the center of screw barrel (3) and fixed disk (4), fixed disk ( 4) It is fixedly connected with the frame (8), and the hopper (1) is installed on the screw barrel (3). Volute (6) is installed around rotating disc (5), and its lower end is closed with frame (8), (the present example volute (6) and frame (8) are integral parts), and its upper end and fixed disc ( 4) closed, the die head (7) is installed on the outlet of the volute (6).

[0034] The gap between the fixed disk (4) and the rotating disk (5) can be controlled by placing a standard plate between the two disks when the fixed disk (4) is assembled on the rotating disk (5). The centering of the screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com