Oil for acrylic acrylic filature

A technology for spinning oil and acrylic fiber, applied in the field of acrylic fiber oil, can solve the problems of poor bundling, difficult acrylic fiber production process, etc., and achieve the effects of good bundling and excellent smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

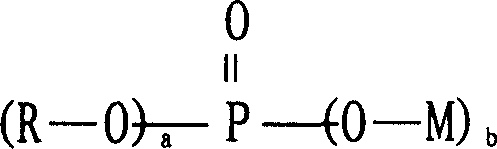

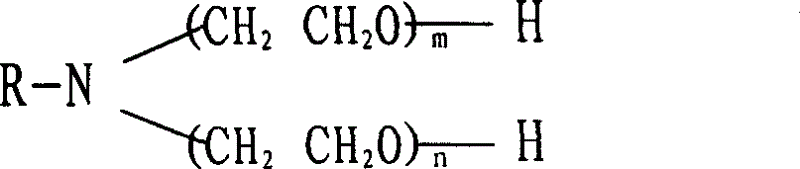

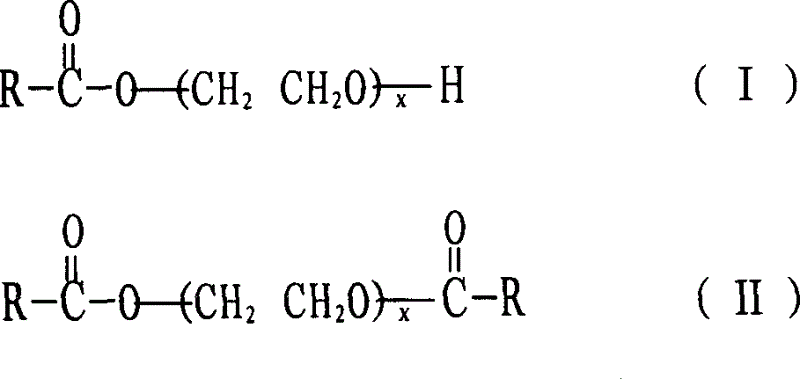

Method used

Image

Examples

Embodiment 1~10

[0023] Prepare components A, B, C and D according to the required ratio with warm water at 60°C to prepare the emulsion with the required concentration, and the concentration of the emulsion in the upper oil tank is controlled at 2±0.5%. Embodiment 1 ~ is used for the spinning oiling of 3.33dtex * 105mm acrylic fiber, embodiment 5 ~ 6 is used for the spinning oiling of 6.66dtex * 113mm acrylic fiber, embodiment 7 ~ 10 is used for the filament bundle of 3.33dtex After spinning and oiling, the tow passes through a multi-zone breaking machine to make wool tops. The fiber oiling rate of Examples 5-6 is controlled at 0.35±1%, and the others are controlled at 0.3±1%. The fiber shows good spinnability and processing performance in the spinning process and the post-processing process, and the prepared fiber is soft and smooth, and has a good hand feeling.

[0024] The specific components A, B and C of each embodiment are shown in Table 1, and the weight ratio of components A, B and C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com