Heat accumulation type energy-saving infrared burner

An infrared burner and heat-gathering technology, which is applied in the field of kitchen utensils, can solve the problems of large heat loss, low thermal efficiency utilization rate, and short service life, and achieve the effect of high thermal efficiency utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

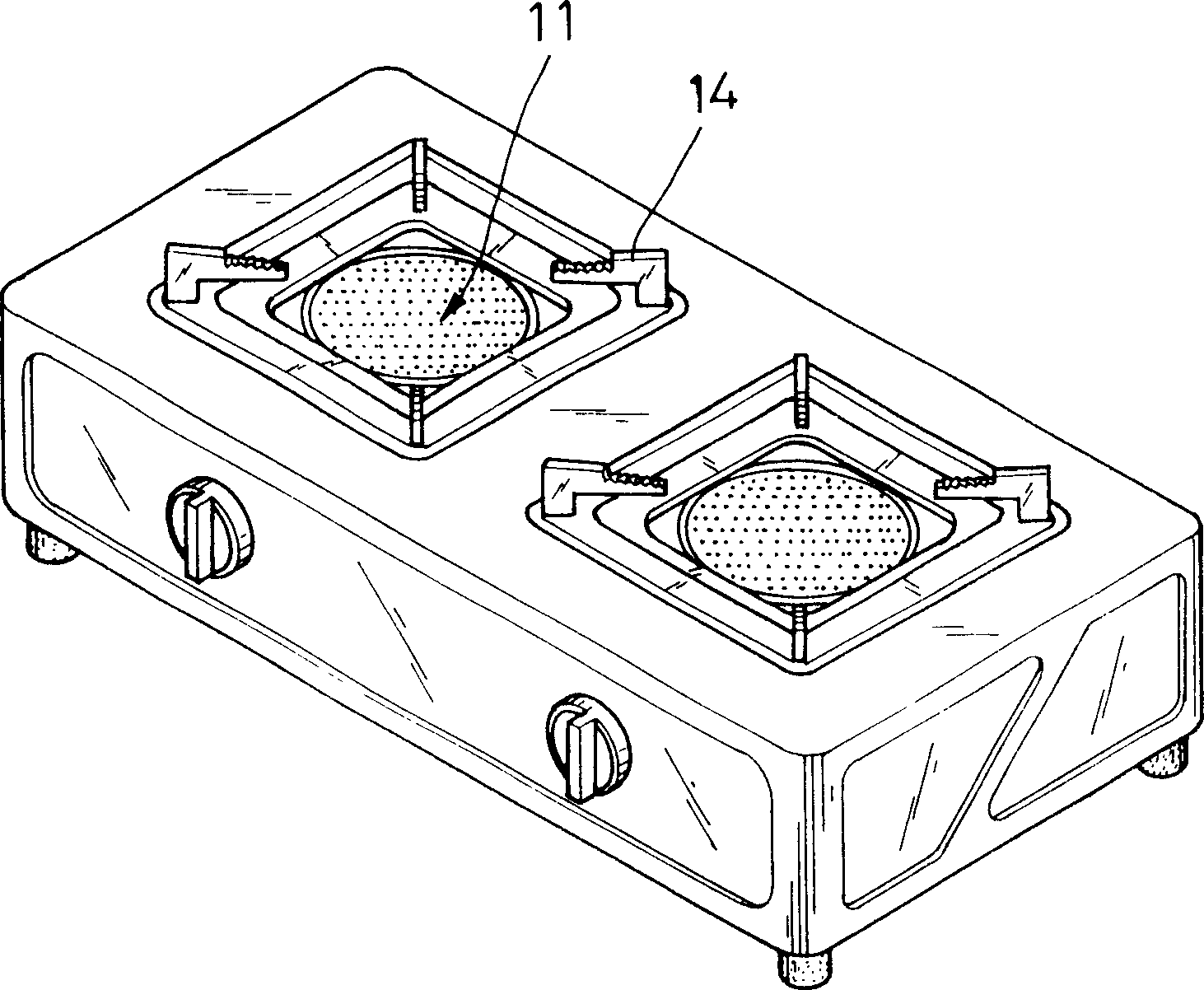

[0044] First, refer to Figure 4 and match Figure 5 , 6 , 7, is a feasible embodiment of the present invention, which includes:

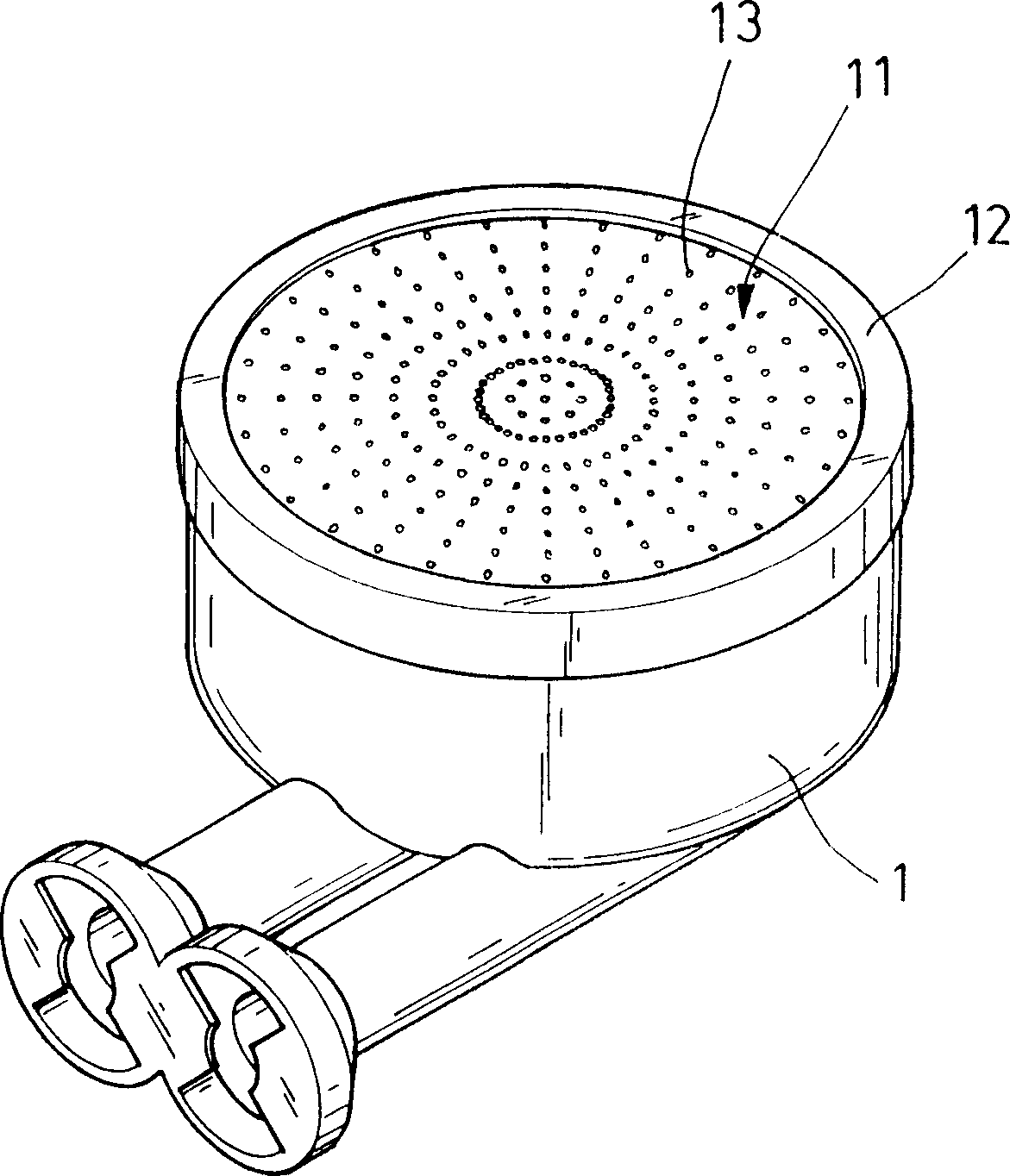

[0045] A burner body 1, above which accommodates an infrared ceramic plate 11 with a plurality of small flame holes 13;

[0046] A ring frame 2 is composed of an upper frame 21 and a lower frame 22 and is arranged on the upper edge of the burner body 1. A hollow annular exhaust passage 23 is formed inside, and the top surface 211 of the upper frame 21 is higher than the infrared ceramic plate 11, which extends inwardly from the top surface 211 to form an inner ring surface 212, and the inner ring surface 212 is provided with a plurality of exhaust holes 213;

[0047] The outer surface of the ring frame 2 is provided with an air outlet 24 .

[0048] Furthermore, the inner ring surface 212 of the upper frame 21 is provided with a V-shaped groove 214 protruding inward under the exhaust hole 213 , and a plurality of overflow holes 215 are provided ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com