Elastic surface wave element suitable for gigahertz frequency band

A surface acoustic wave and surface wave technology, applied in electrical components, impedance networks, etc., can solve problems such as no records, and achieve the effect of suppressing the increase in resistance, reducing insertion loss, and improving the performance of stress migration resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

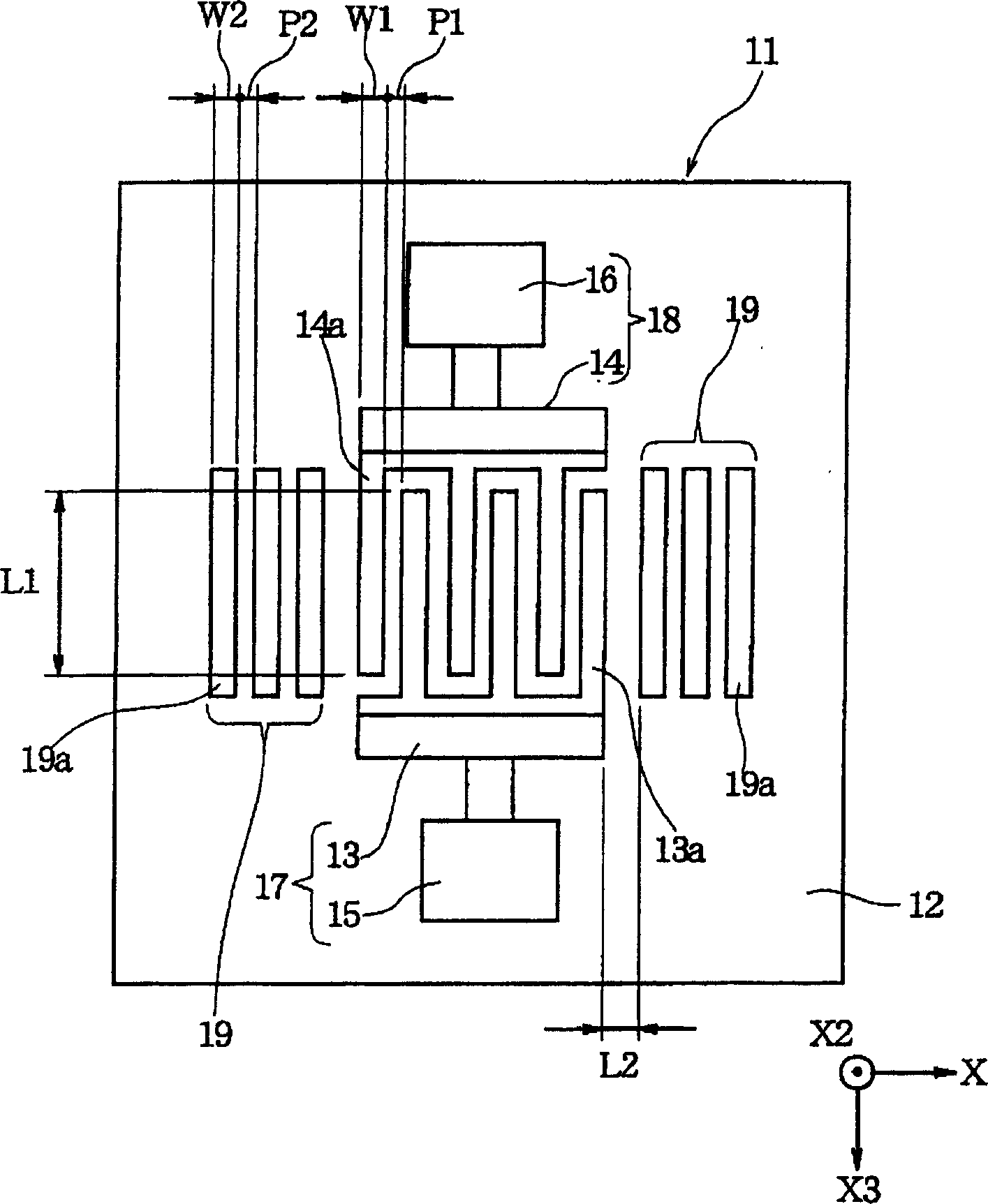

[0037] figure 1 It is a plan view showing a surface acoustic wave device according to an embodiment of the present invention.

[0038] Reference numeral 11 denotes a surface acoustic wave element which functions as a resonator.

[0039] Reference numeral 12 denotes a piezoelectric substrate. In this embodiment, the piezoelectric substrate 12 is formed of LiTaO3.

[0040]Comb-tooth-shaped electrode portions 13 and comb-tooth-shaped electrode portions 14 are formed on the piezoelectric substrate 12 . A comb-toothed portion 13 a extending in a direction opposite to the illustrated X3 direction and a comb-toothed portion 14 a extending in the illustrated X3 direction are formed in the comb-toothed electrode portion 13 and the comb-toothed electrode portion 14 . The comb-toothed portion 13 a of the comb-toothed electrode portion 13 and the comb-toothed portion 14 a of the comb-toothed electrode portion 14 are arranged at predetermined intervals so as to be different from each ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com