Program supply method of substrate mounting production line

A technology of production line and application program, which is applied in the direction of program control device, electrical program control, program loading/starting, etc. It can solve the problems that customers are difficult to change the device structure, difficult server control and billing, etc., to achieve production efficiency and reduce defective products The effect of the incidence of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] Hereinafter, preferred embodiments of the method and system for providing a program for a board mounting line according to the present invention will be described in detail with reference to the drawings.

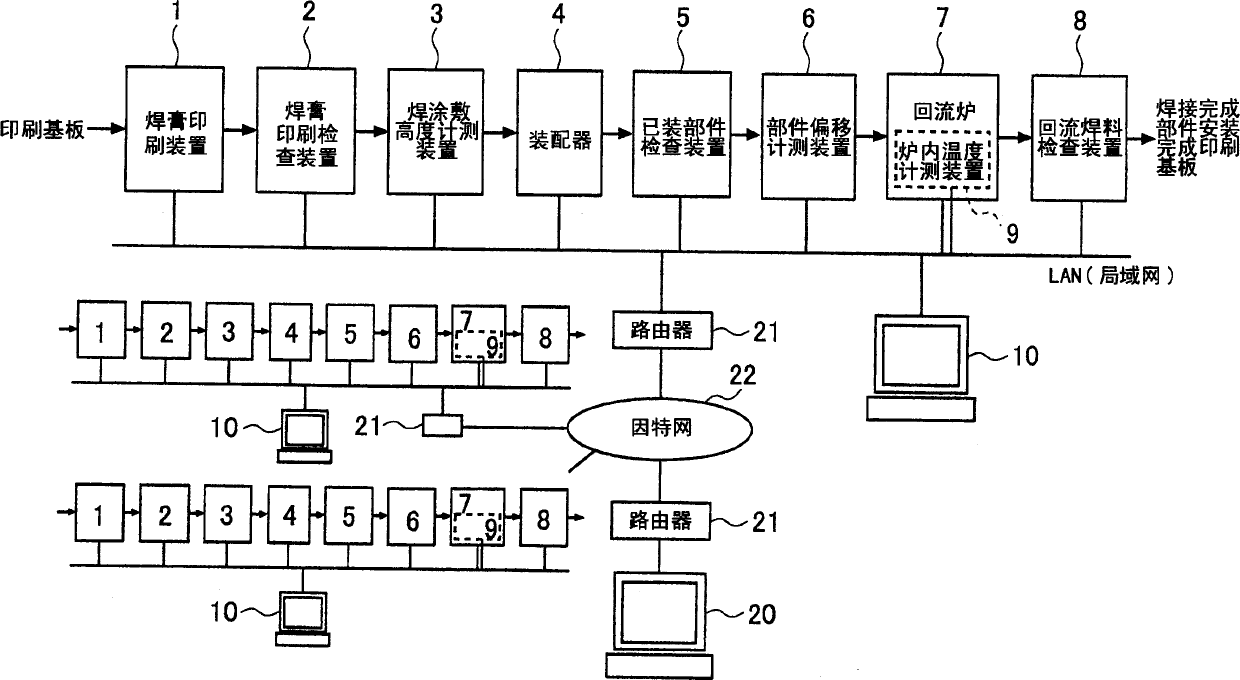

[0081] First, the overall configuration of the system that is the premise of the method of the present invention, that is, a system composed of a substrate mounting line, a substrate mounting line summary computer, and an application server will be described. FIG. 1 shows a system diagram of a network connecting a substrate mounting line summary computer and an application server.

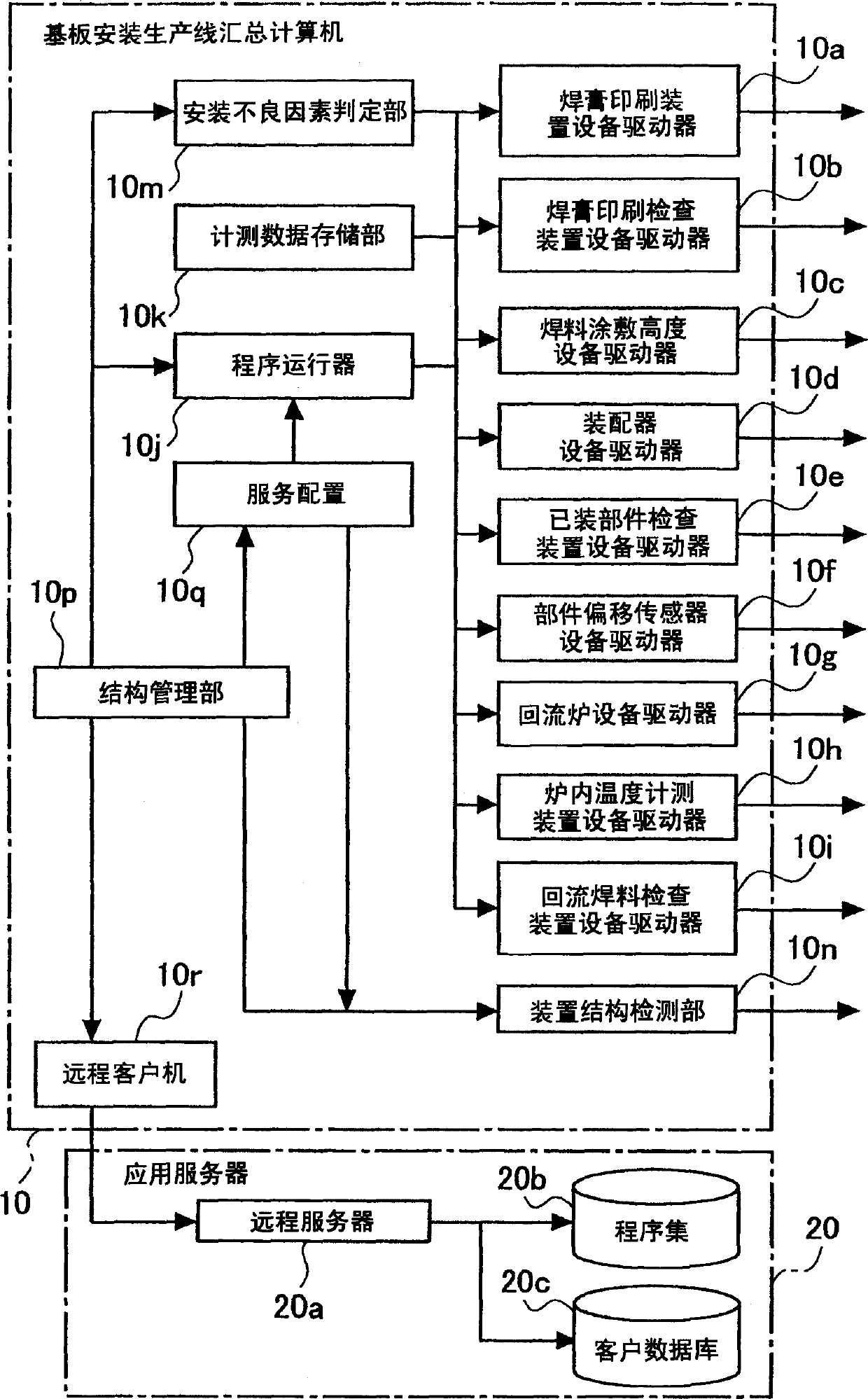

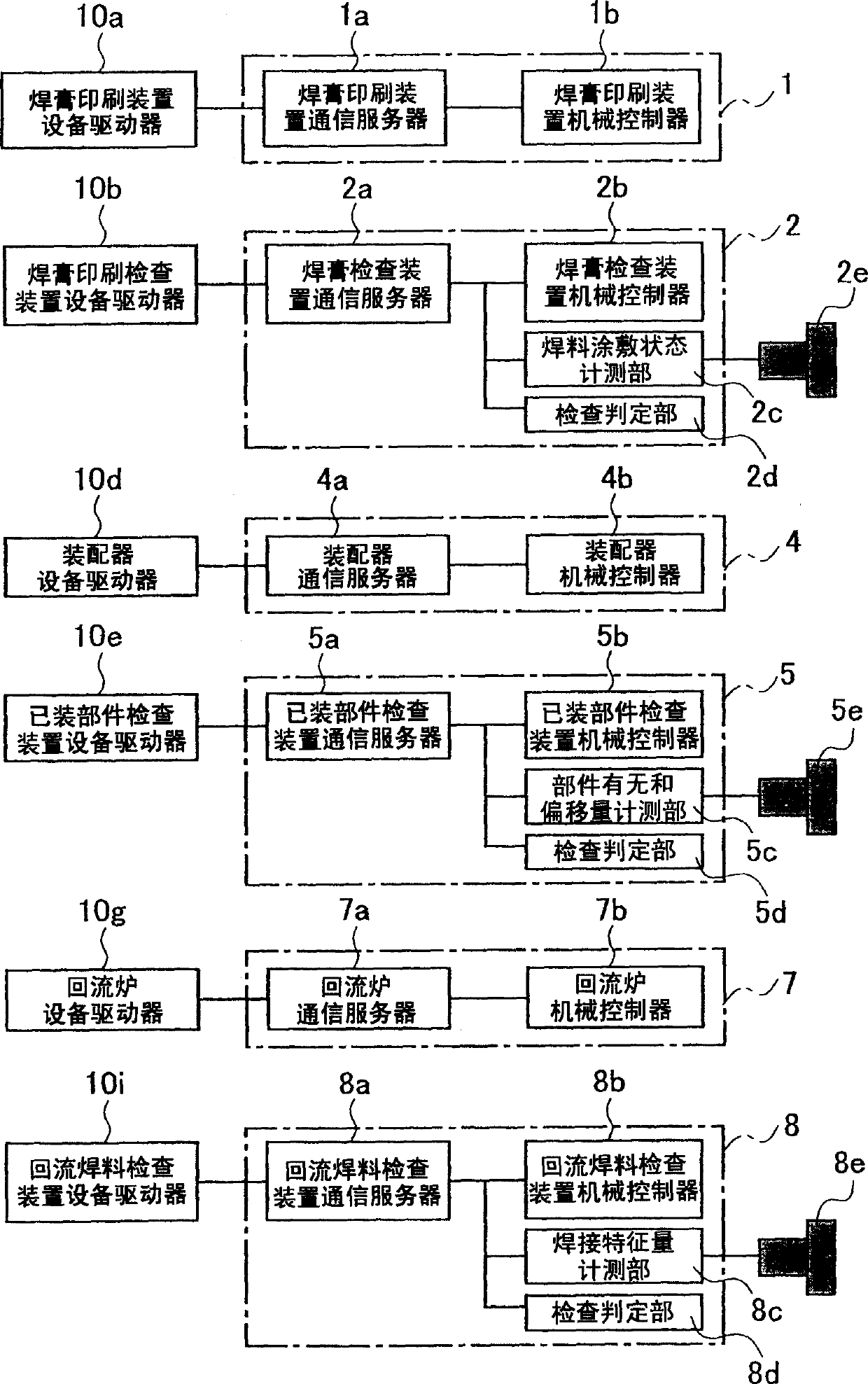

[0082] As shown in the figure, in this system, each device (equipment) 1 to 9 constituting the board mounting line is connected through the Internet 22, and a board mounting line summary computer 10 connected to these devices 1 to 9 with a LAN (Local Area Network) stores application information. The application server 20 provides application programs for the substrate mounting line summar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com