Portable air compressor

An air compressor and air compression technology, which is applied in the direction of liquid variable capacity machinery, mechanical equipment, variable capacity pump components, etc., can solve the problems of heat storage tanks, lower production efficiency, and the assembly of assemblers is not allowed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Reference will now be made in detail to the preferred embodiments of the present invention, examples of which are illustrated in the accompanying drawings.

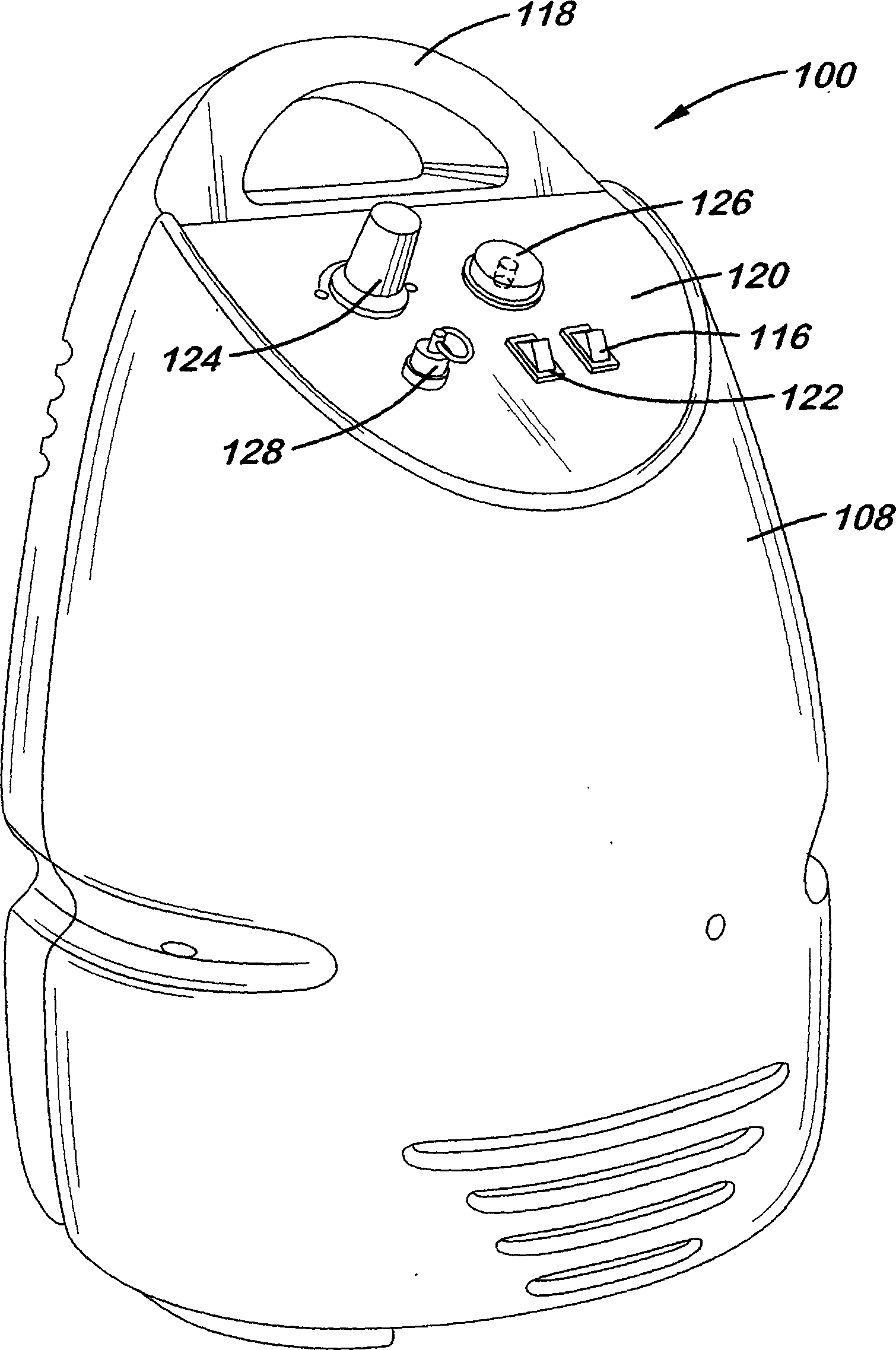

[0051] Now please refer to the general Figure 1-40 , which shows a typical embodiment of a portable air compression device according to the present invention. It should be understood that the portable air compression device refers to an air compression device that can be easily carried and / or moved, rather than being a structural limitation. now refer to Figure 1-13 , the portable air compression device 100 includes an air tank 102 (or 202 ), an air compressor 104 and a conduit 106 mounted within a housing or tank 108 . The shield 108, preferably made of plastic, may contain a handle 118 and a control panel 120, the handle 118 allows the operator to lift the portable air compression unit 100 and transport it from one place to another, the Control panel 120 provides control of the portable air compression devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com