Method for electric power generation using thermonuclear fusion energy

A technology of thermonuclear fusion and turbogenerator, applied in nuclear power generation, nuclear power plants, and reactions to electric energy, etc., can solve the problems of inability to use nuclear fusion energy peacefully, and achieve the effect of unlimited fuel sources and cheap prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

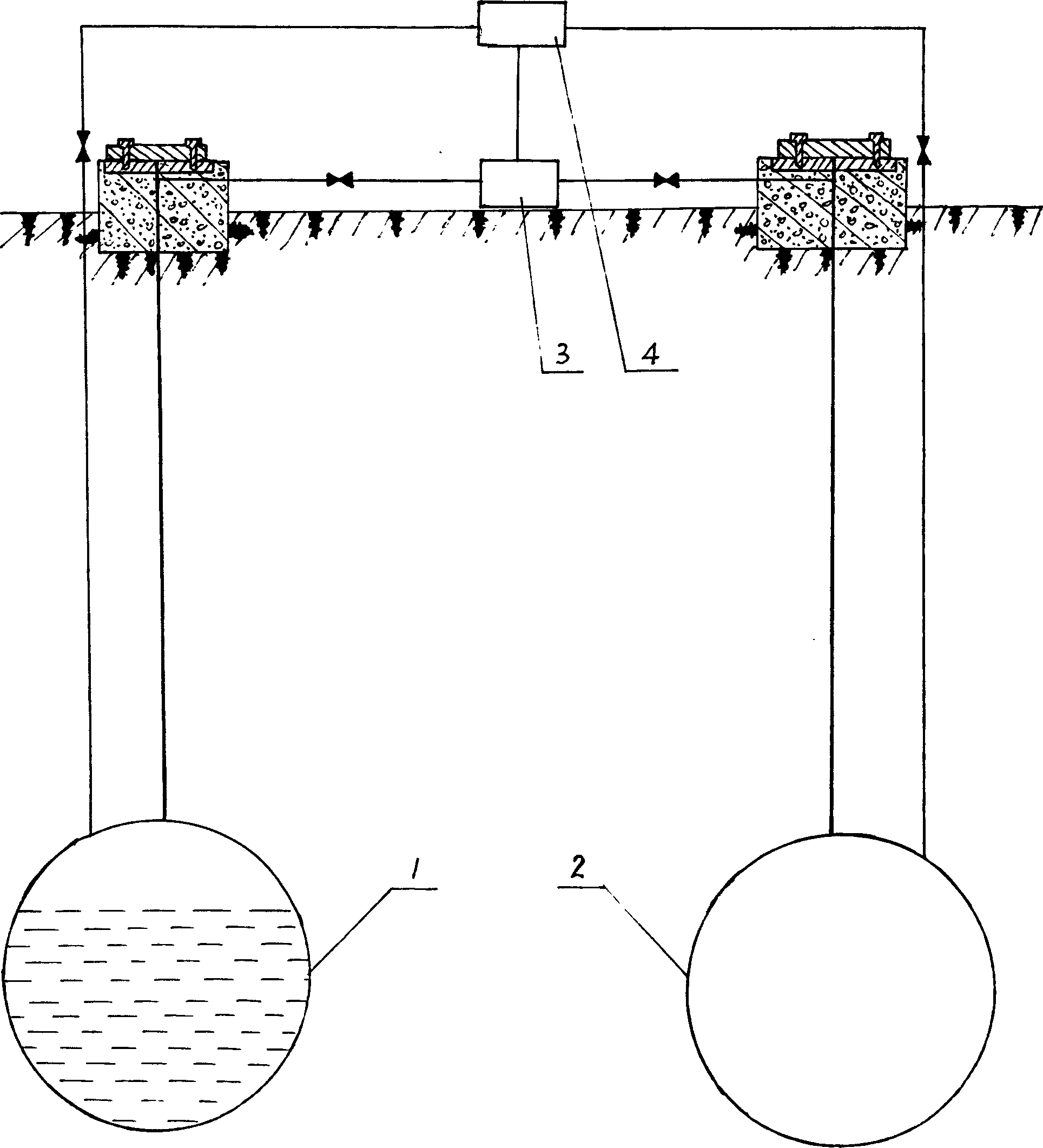

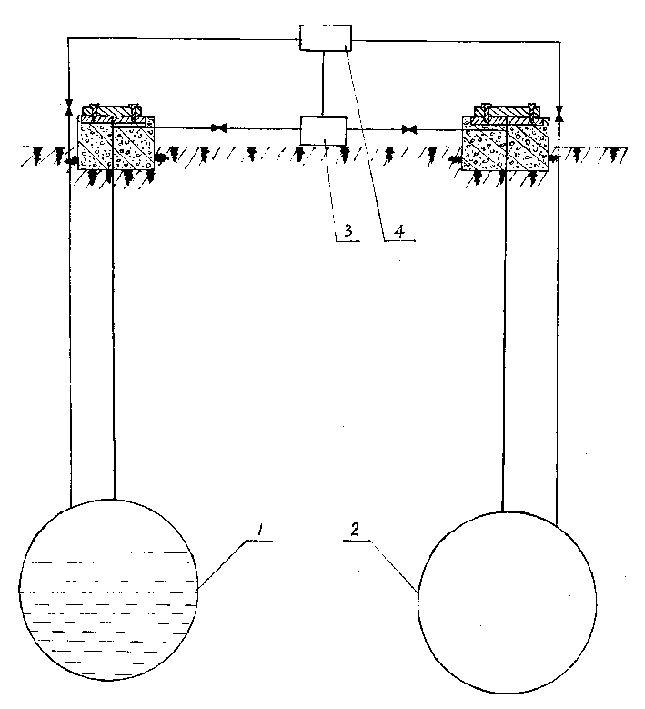

Embodiment 1

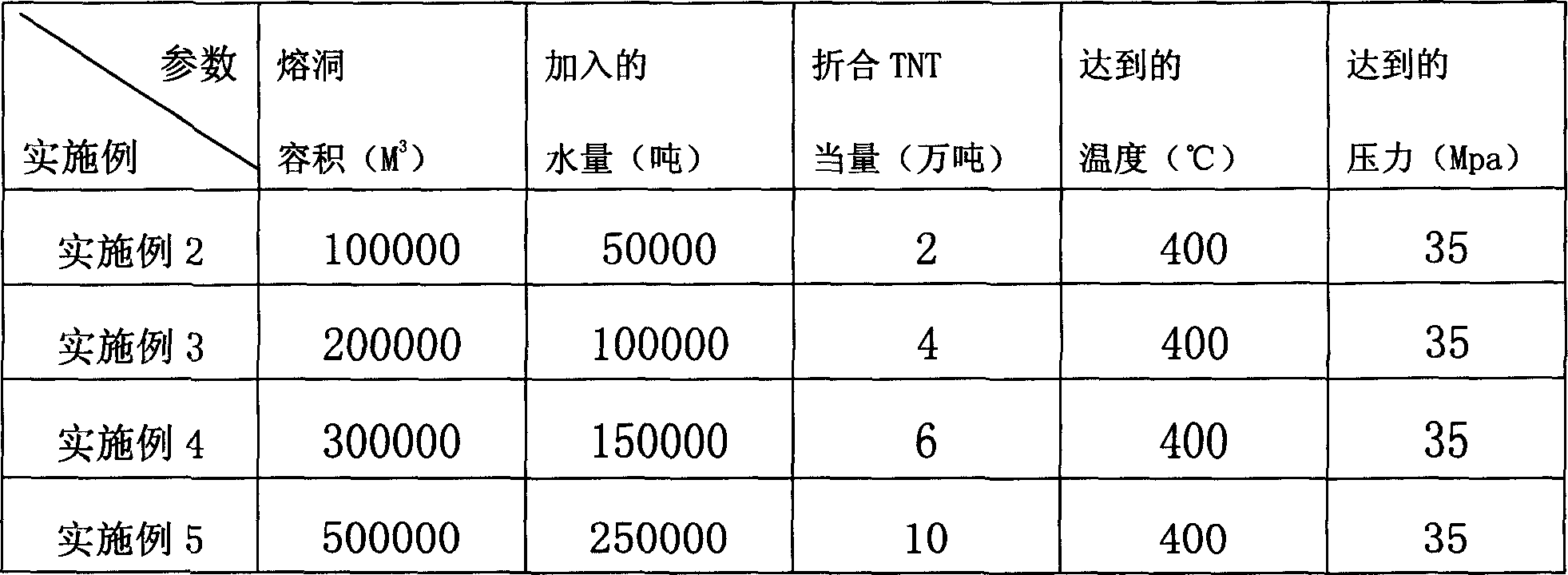

[0029] Example 1: At 40 x 10 4 m 3 Volume of subterranean cavern 1 injected with 20×10 4 m 3 normal temperature water, and put a hydrogen bomb equivalent to 80,000 tons of TNT in the water of the melting cave 1, close the outlets of the melting cave, so that a closed equal-volume system is formed in the melting cave 1, and then detonate the put hydrogen bomb, so that The water in the cave forms a state of high-temperature and high-pressure water vapor at 400°C and 35Mpa, and the steam pipe valve between the cave 1 and the turbo-generator 3 is opened, so that the high-temperature and high-pressure steam drives the turbo-generator to rotate and generate power to generate power. After the exhaust steam is condensed by the condenser 4, it enters another 40×10 4 m 3 volume of underground cave 2, when the high-temperature and high-pressure steam in the cave 1 is finished, the water in the cave 2 is adjusted to 20×10 4 m 3 Afterwards, put a hydrogen bomb equivalent to 80,000 to...

Embodiment 6

[0032] Embodiment 6: The difference between this embodiment and the above embodiment is that three underground melting caves are connected to the turbo generator through pipelines at the same time, and the condensate inlets of each melting cave are respectively connected to the condenser outlets through return pipes. When the power generation operation of two of the caves is about to end, the hydrogen bomb in the water in the other cave can detonate in time and generate high-temperature and high-pressure water vapor, which can provide power for the turbo-generator in time to generate electricity, so that the turbo-generator can be continuously and uninterrupted. Provide power to keep the entire power generation process continuous, and enable the molten cave to fully cool down and eliminate internal stress.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com