High-temp resisting petroleum downhole dynamic pressure sensor

A technology of dynamic pressure and oil wells, applied in fluid pressure measurement by changing ohmic resistance, electric solid devices, wellbore/well components, etc., can solve the problem of difficult measurement of downhole pressure in oil and gas wells, and achieve the effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] specific implementation plan

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings.

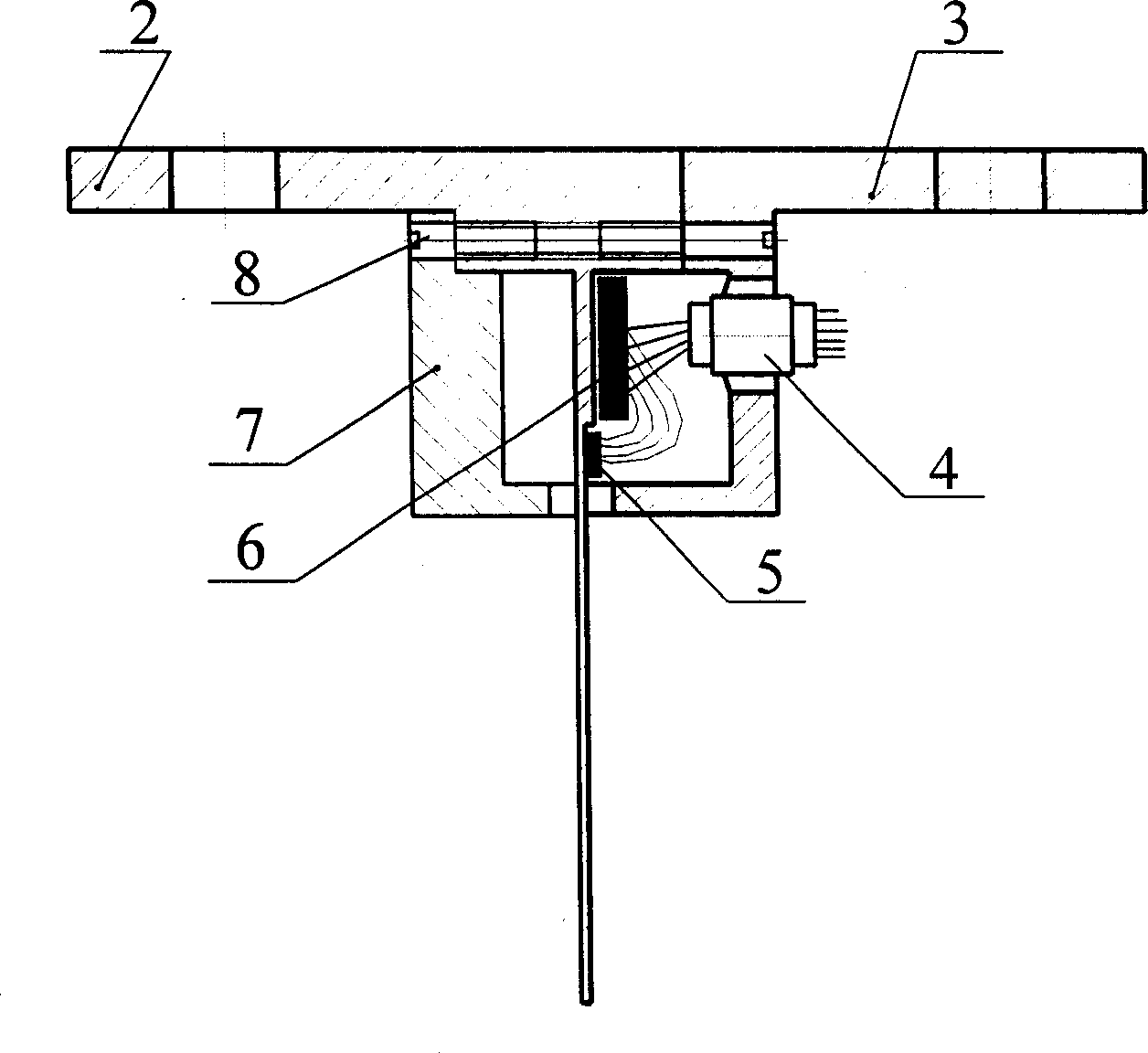

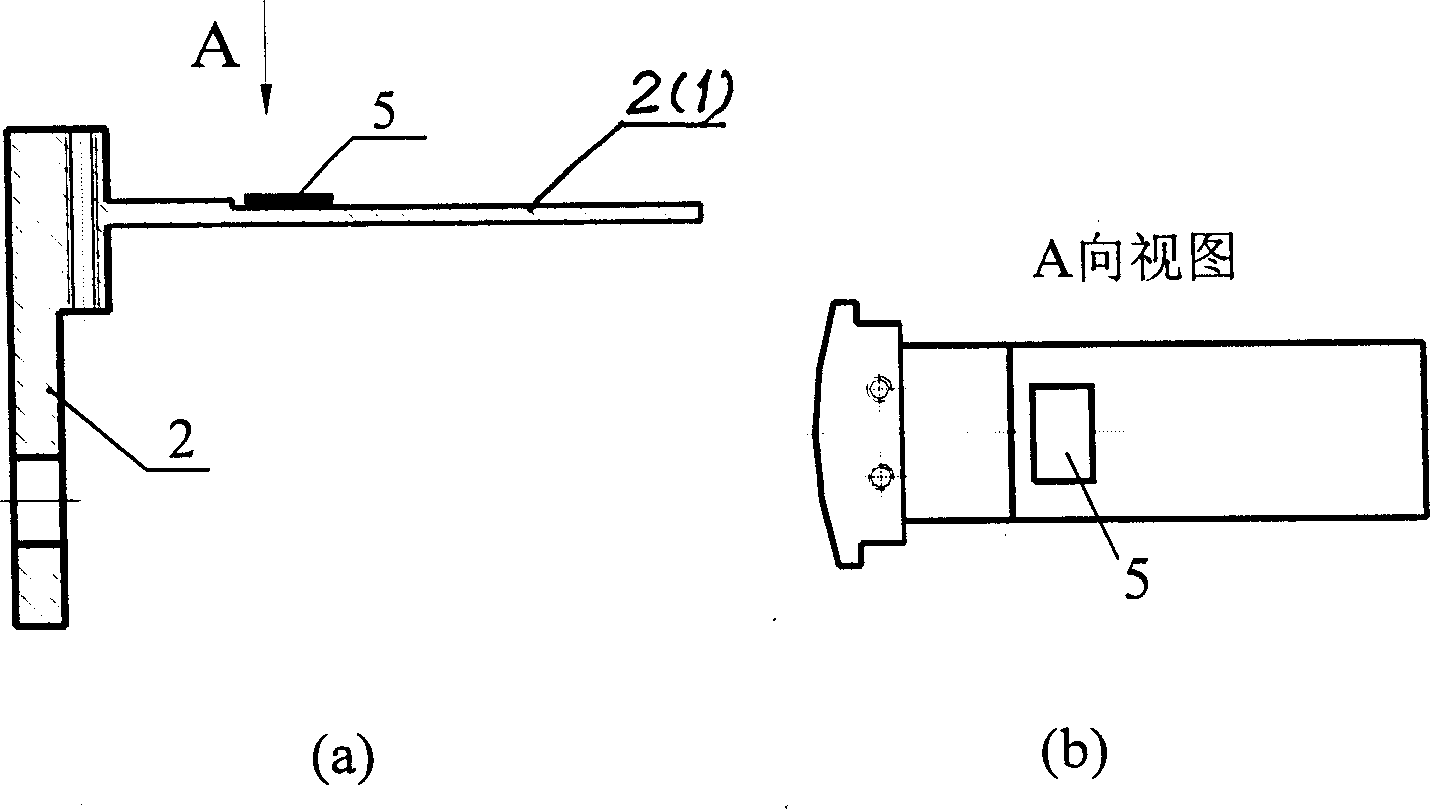

[0013] according to figure 1 , the sensor is composed of elastic element 2, main protection cover 3, secondary protection cover 7, SOI silicon micro solid piezoresistive chip 5, high temperature circuit board 6 and high temperature transmission wire 4, elastic element 2 and main protection cover 3, secondary The protective cover plate 7 is connected together by screws 8, and the elastic element 2 is designed as a T-shaped cantilever beam structure, that is, a downward cantilever beam 2 (1) is designed at the bottom right of the elastic element 2, and the cantilever beam 2 on the elastic element 2 The upper part of (1) is designed with a step, and the SOI silicon micro-solid piezoresistive chip 5 is bonded under the step of the elastic element 2 cantilever beam 2 (1) through eutectic welding or other packaging processes, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com