Method for monitoring overlaying alignment on wafer

A wafer and overlay error technology, applied in the field of monitoring overlay alignment accuracy, can solve problems such as uncertain relative test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

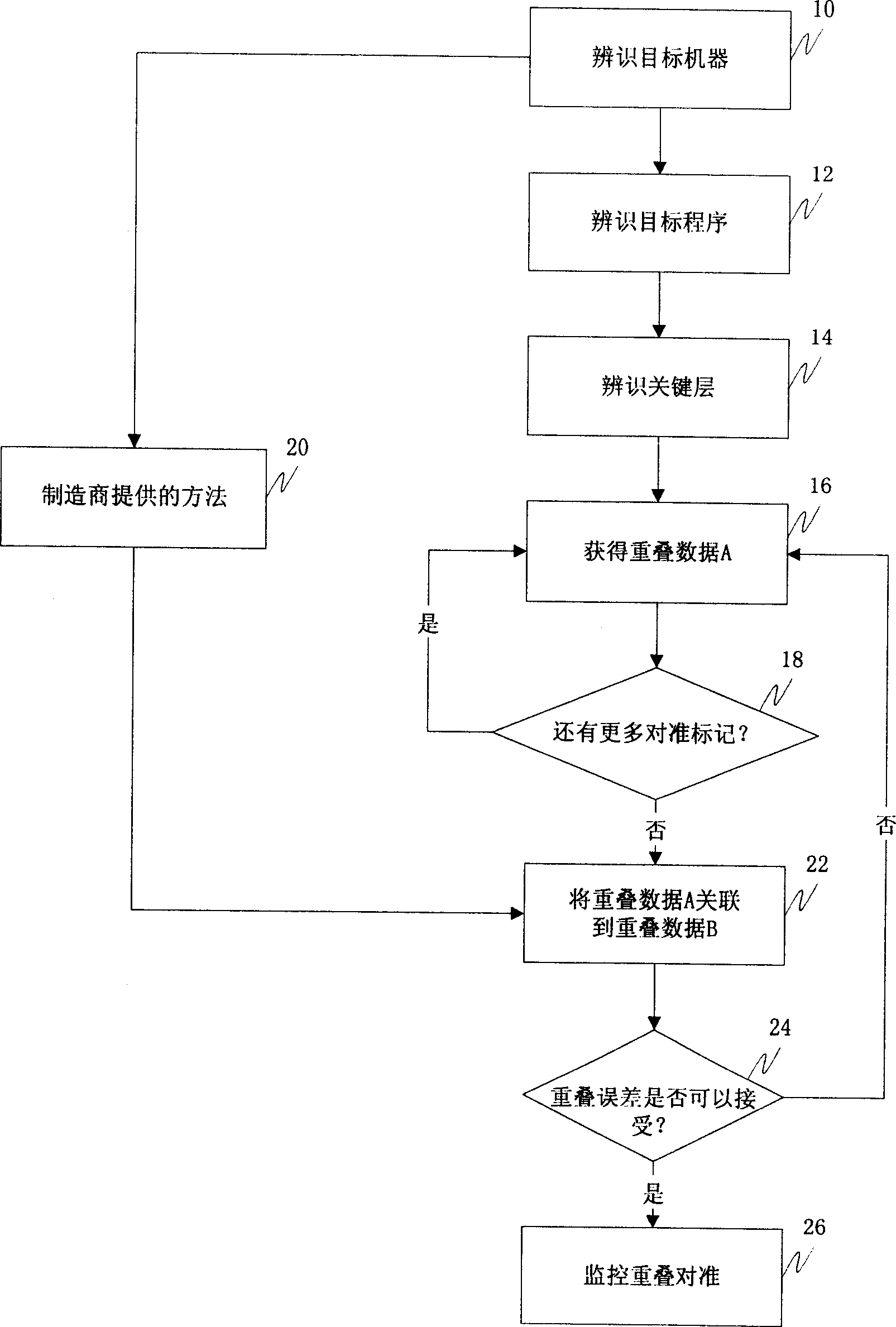

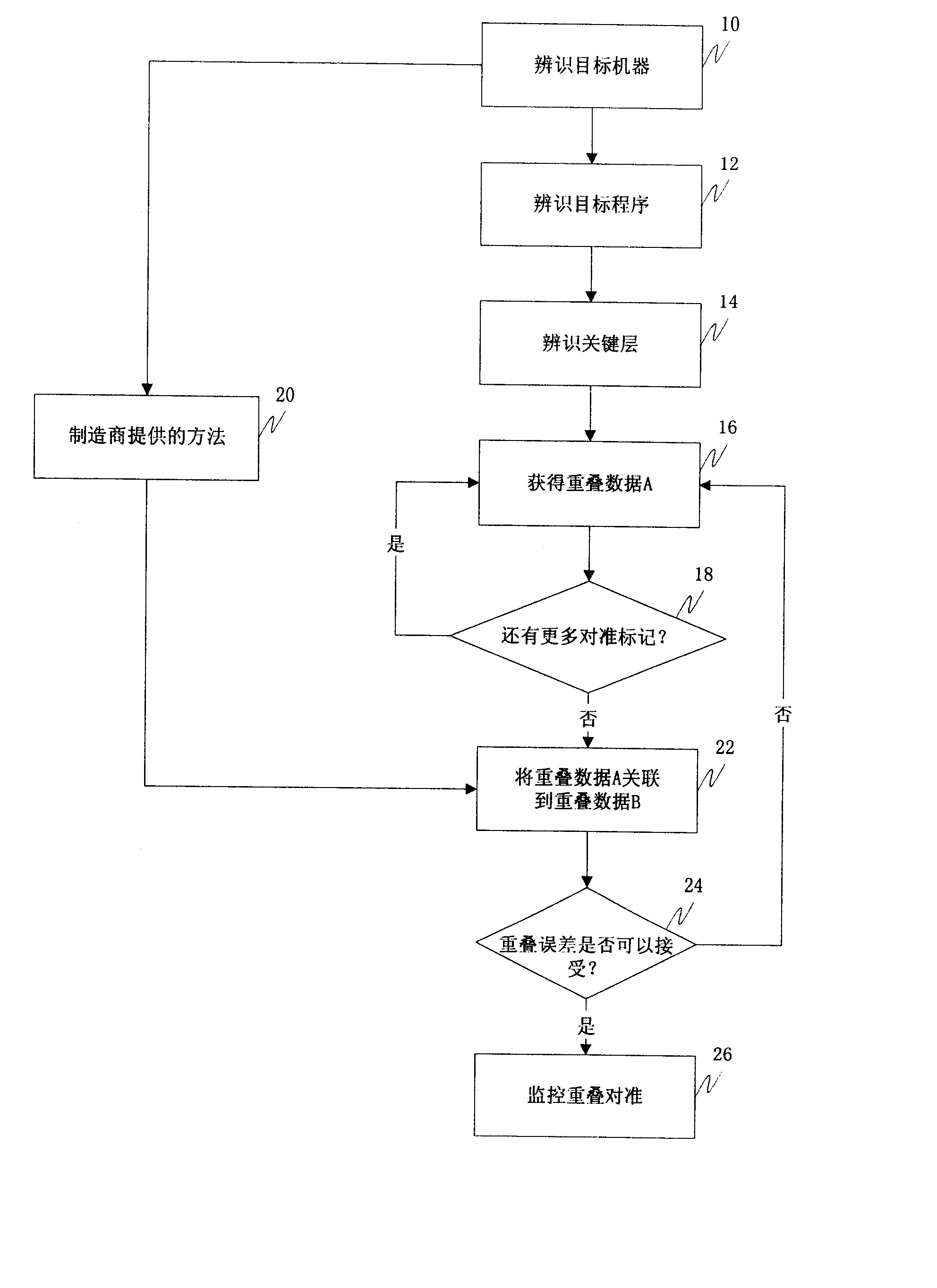

[0012] The preferred embodiments of the present invention will be described in detail below with the accompanying drawings. Whenever possible, the same reference numbers will be used when referring to the same or like components in the drawings.

[0013] The present invention provides a monitoring system that improves upon and replaces known methods (such as machine pair testing) and is used to monitor overlay alignment. The monitoring system of the present invention only needs to use five positioning patterns to monitor overlay alignment. Since only a few positioning patterns need to be used to measure overlay data, the down-time of the stepper can be greatly reduced. In addition, the monitoring system of the present invention will also improve the accuracy and reliability of known alignment monitoring methods because the overlay data used to monitor overlay alignment does not need to come from the same stepper.

[0014] figure 1 It is a flowchart of an embodiment of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com