Multicolor composite ink used for inkjet printing machine

An inkjet printer and ink technology, applied in the directions of inks, applications, household appliances, etc., can solve problems that are not involved or can not be solved by methods, and achieve the effect of preventing color bleeding and improving drying speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

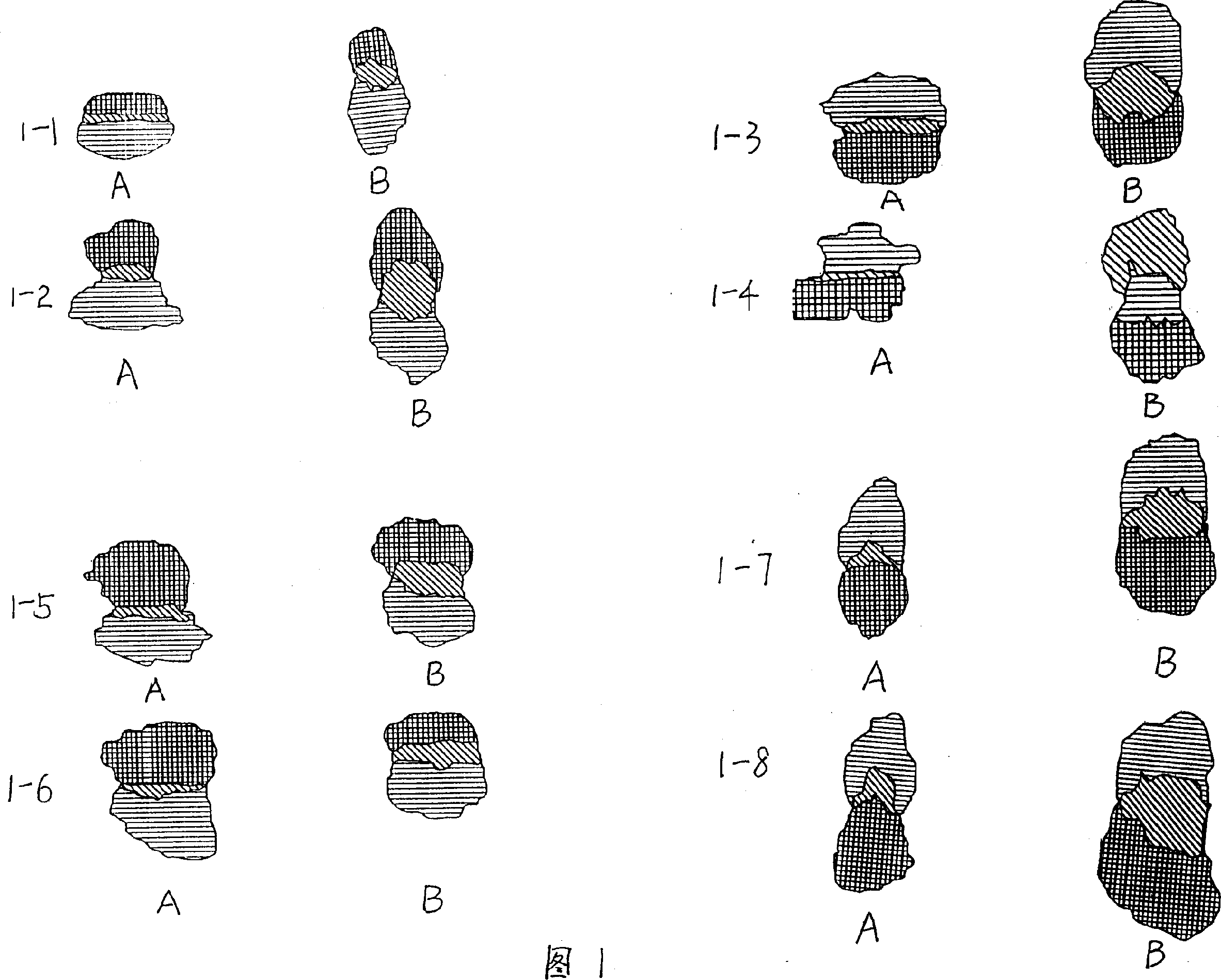

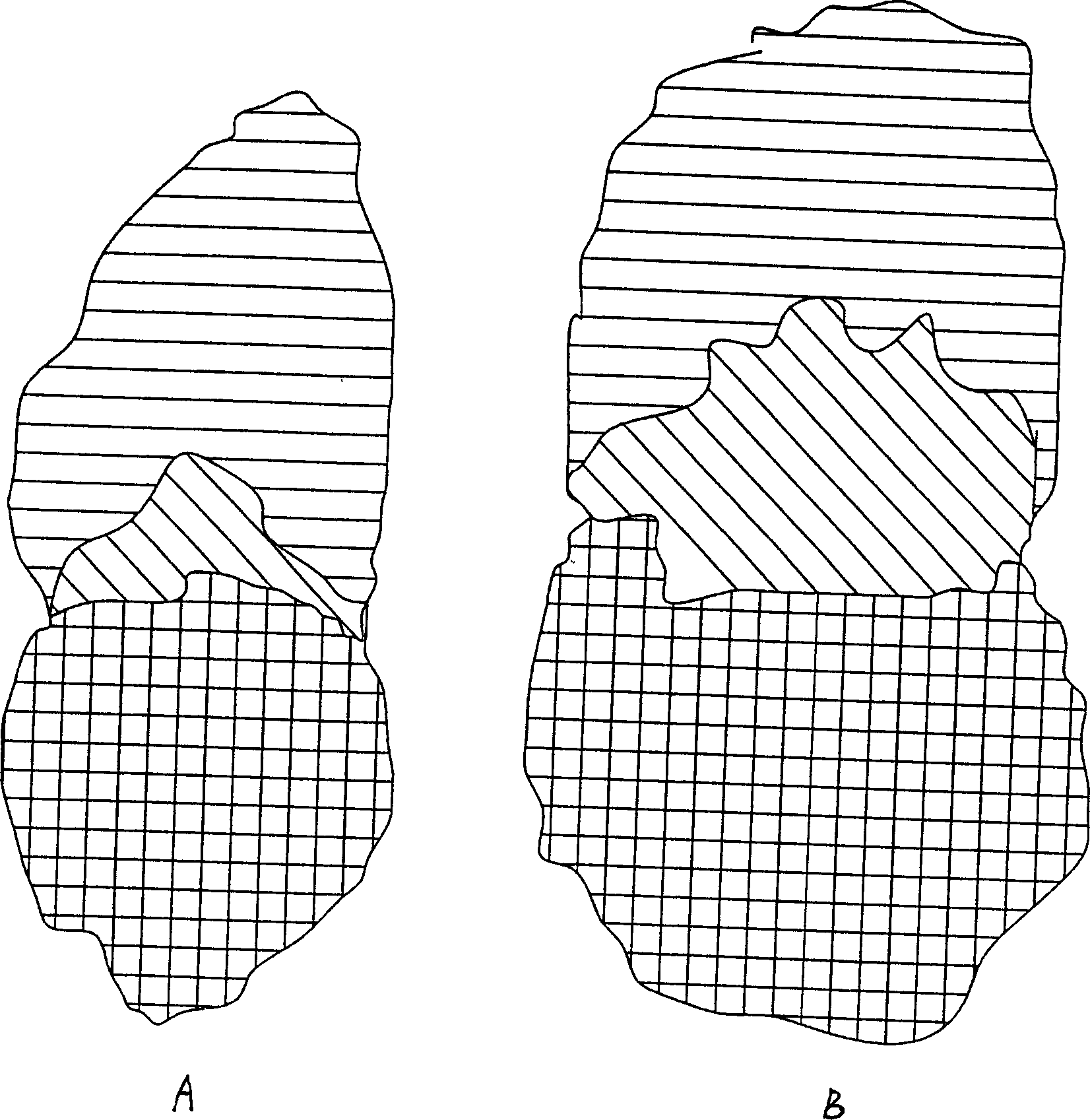

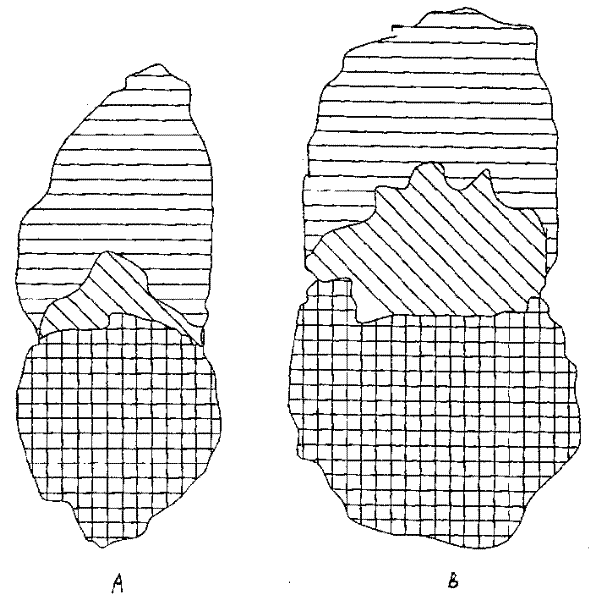

Image

Examples

example 1

[0042] Example 1 Inkjet printer with six-color combination ink

[0043] The components of the six-color ink are as follows

[0044] component name

black

red

yellow

blue

light red

light blue

Colorant

Kohuasu

excel black

5%

direct blend

Red 227

4%

direct blend

Yellow 86

3%

direct light fastness

Blue 86

6%

Kohuasu

excel red

1.8%

Acid Blue 9

1.0%

NOFO

0.1%

NOFO

0.1%

NOFO

0.1%

NOFO

0.1%

NOFO

0.1%

NOFO

0.1%

KATHON®L

XE 0.2%

KATHON®L

XE 0.1%

KATHON®L

XE 0.1%

KATHON®L

XE 0.1%

KATHON®L

XE 0.1%

KATHON®L

XE 0.5%

Diffusion agent

N,N-Dimethicone

methyl formamide

0.5%

N,N-Dimethicone

methyl formamide

0.2%

N,N-Dimethicone

methyl formamide

0.1%

...

example 2

[0055] Example 2 Inkjet printer with six-color combination ink

[0056] component name

black

red

yellow

blue

light red

light blue

Colorant

Direct Black 154

5%

direct light fastness

Red 79

4%

direct blend

Yellow 86

3%

direct light fastness

Blue 199

6%

Kohuasu

excel red

1.8%

Acid Blue 9

1.2%

NOFO

0.1%

NOFO

0.1%

NOFO

0.1%

NOFO

0.1%

NOFO

0.1%

NOFO

0.1%

KATHON®L

XE 0.15%

KATHON®L

XE 0.18%

KATHON®L

XE 0.10%

KATHON®L

XE 0.12%

KATHON®L

XE 0.05%

KATHON®L

XE 0.08%

Diffusion agent

N,N-Dimethicone

methyl formamide

0.2%

N,N-Dimethicone

methyl formamide

0.1%

N,N-Dimethicone

methyl formamide

0.3%

N,N-Dimethicone

methyl formamide

0.4%

N,N-Dimethicone

met...

example 5

[0069] Example 5 Inkjet printer with six-color ink

[0070] component name

[0071] Glycolic acid 30%, EDTA 70%. Use color images in inkjet printing with vivid colors and well-defined colors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com