High efficiency torrent phase-change oil water separating method

An oil-water separation and turbulent flow technology is applied in the field of improving the purification and separation method of industrial oil, which can solve the problems of deteriorating oil quality, reducing insulation performance, dehydration effect, etc. Water efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

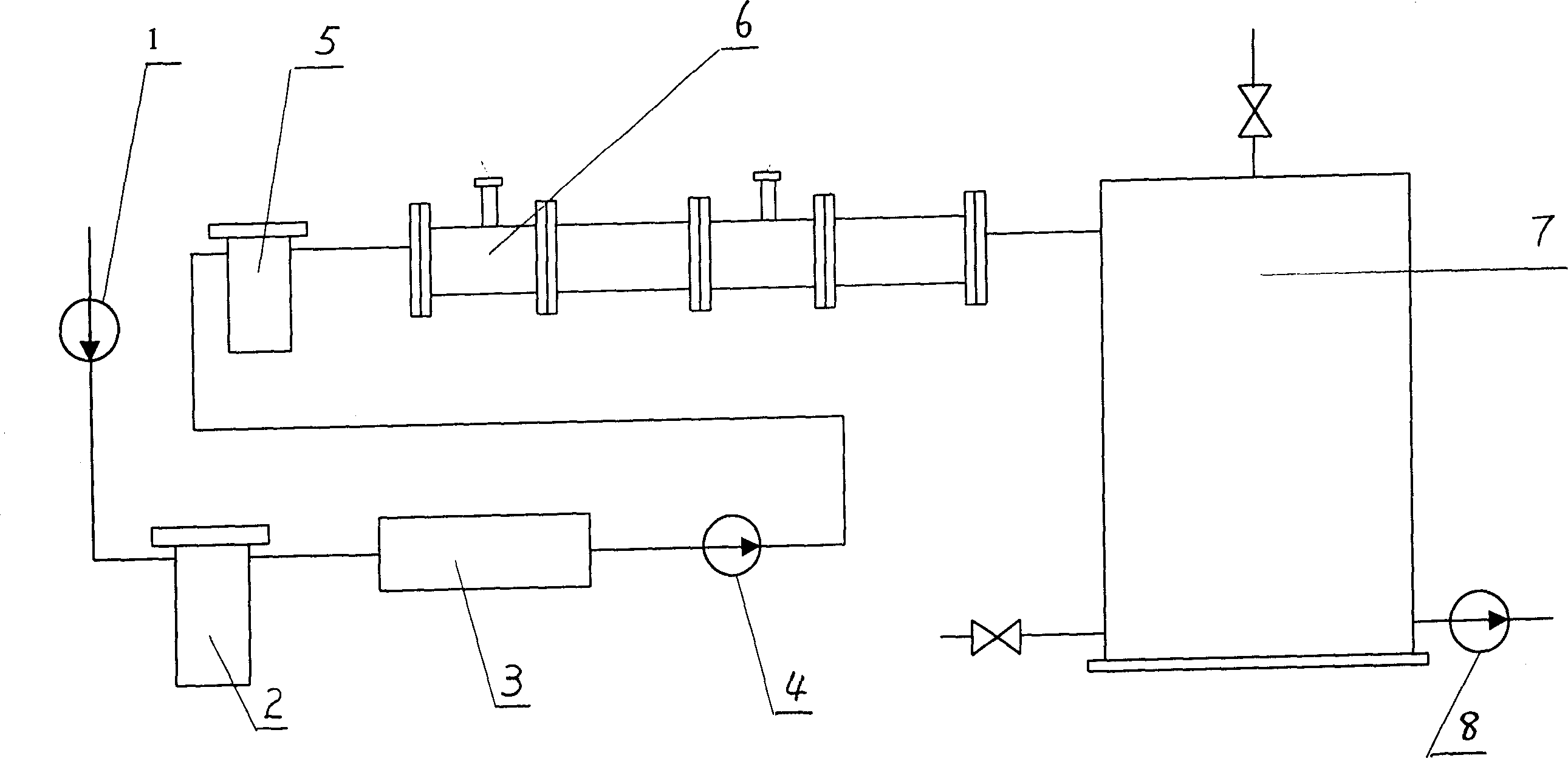

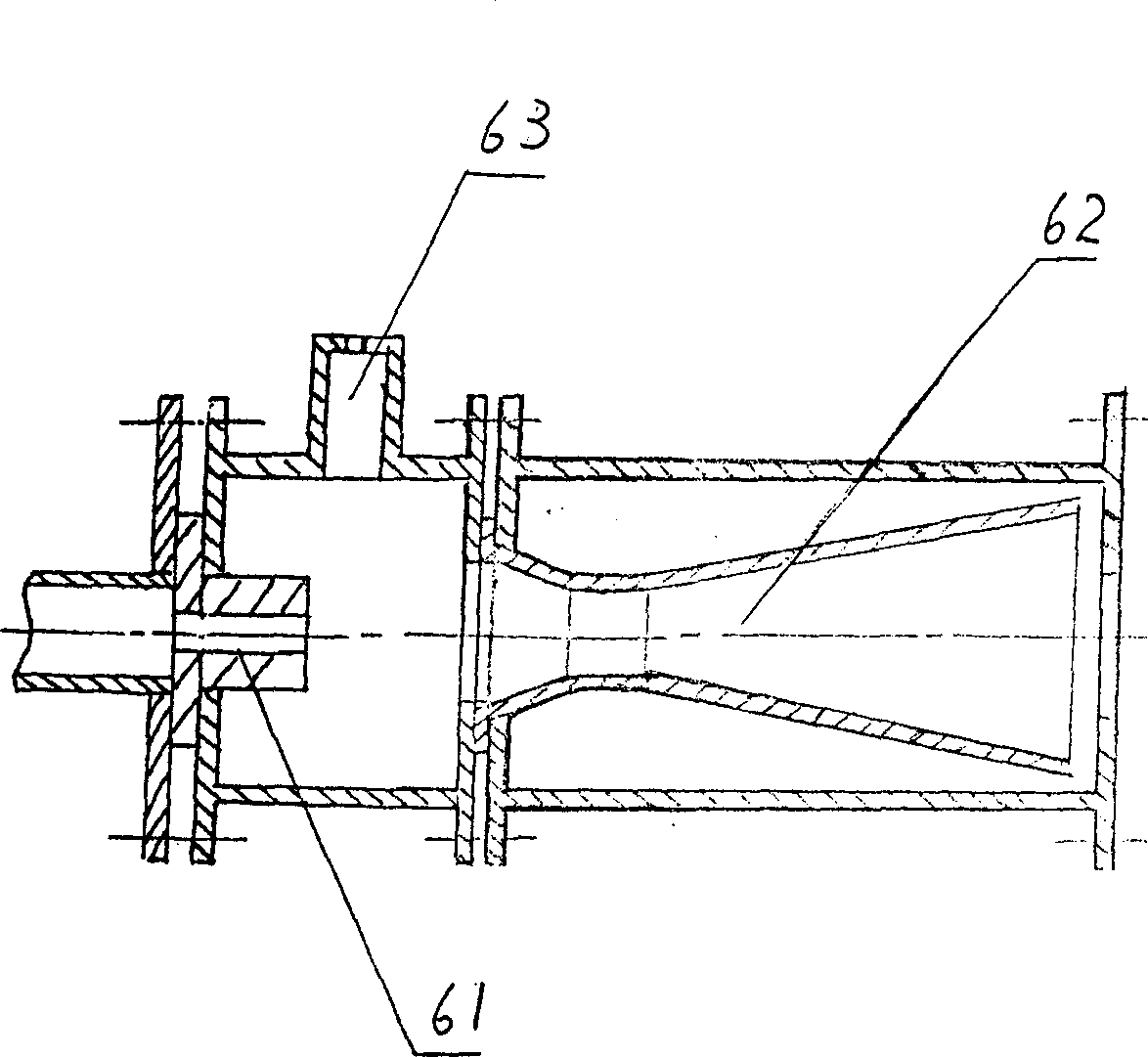

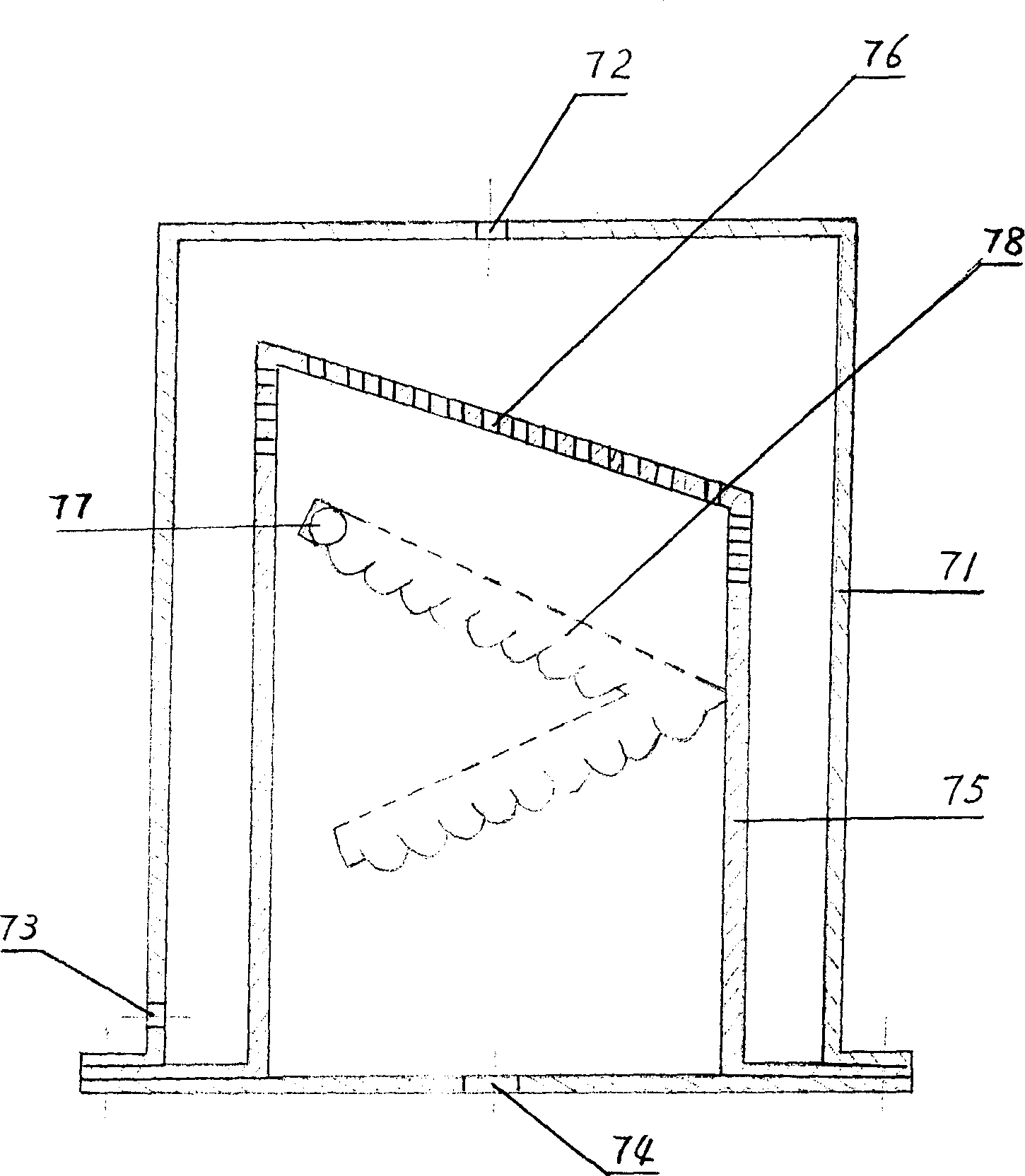

[0018] Contaminated oil passes through the one-stage or two-stage turbulence generator in sequence, and at the same time, air is introduced at the air distribution hole of the turbulence generator to form a multi-phase flow oil-water separation system. The detailed description is as follows: the polluted oil is drawn out from the oil tank through the oil pump, and the impurities are removed through the filter, and then the oil is heated to 50-60°C through a heating device, and the oil that meets a certain temperature requirement enters the first-stage turbulence generator Mixing with inhaled air; contaminated oil has the property of incompressibility, while air has the property of compressibility. During the mixing process of contaminated oil and air, due to the compressibility of air, compression and expansion will occur In this way, the gas and oil mixture can be fully mixed in a turbulent state, and the rapid phase change of water in oil from liquid to vapor is promoted at a...

Embodiment 2

[0022] In Example 1, due to the introduction of air, the gas content in the oil will increase, which will affect the normal operation of the transformer. At the same time, the air contains a certain humidity, and the residual moisture after filtering is difficult to be lower than 20 ml / kg. Therefore, in order to meet the requirements of transformer oil Oil-water separation, remove the turbulence generator air distribution hole and not introduce air.

[0023] When the first-stage air with orifice plate and the second-stage air with orifice plate of the high-efficiency turbulent-flow phase-change oil-water separation device are removed, although there is no introduction of air, the water vapor and oil flow precipitated by the first-stage turbulent flow generator also form two phases Flow, at the outlet of the first-stage turbulence generator and the second-stage turbulence generator, there will be an expansion and compression pulsation cycle, which will increase the contact area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com