Distribution board

A technology of switchboards and conductive rods, applied in electrical components, substation/switch layout details, etc., can solve problems such as troublesome work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

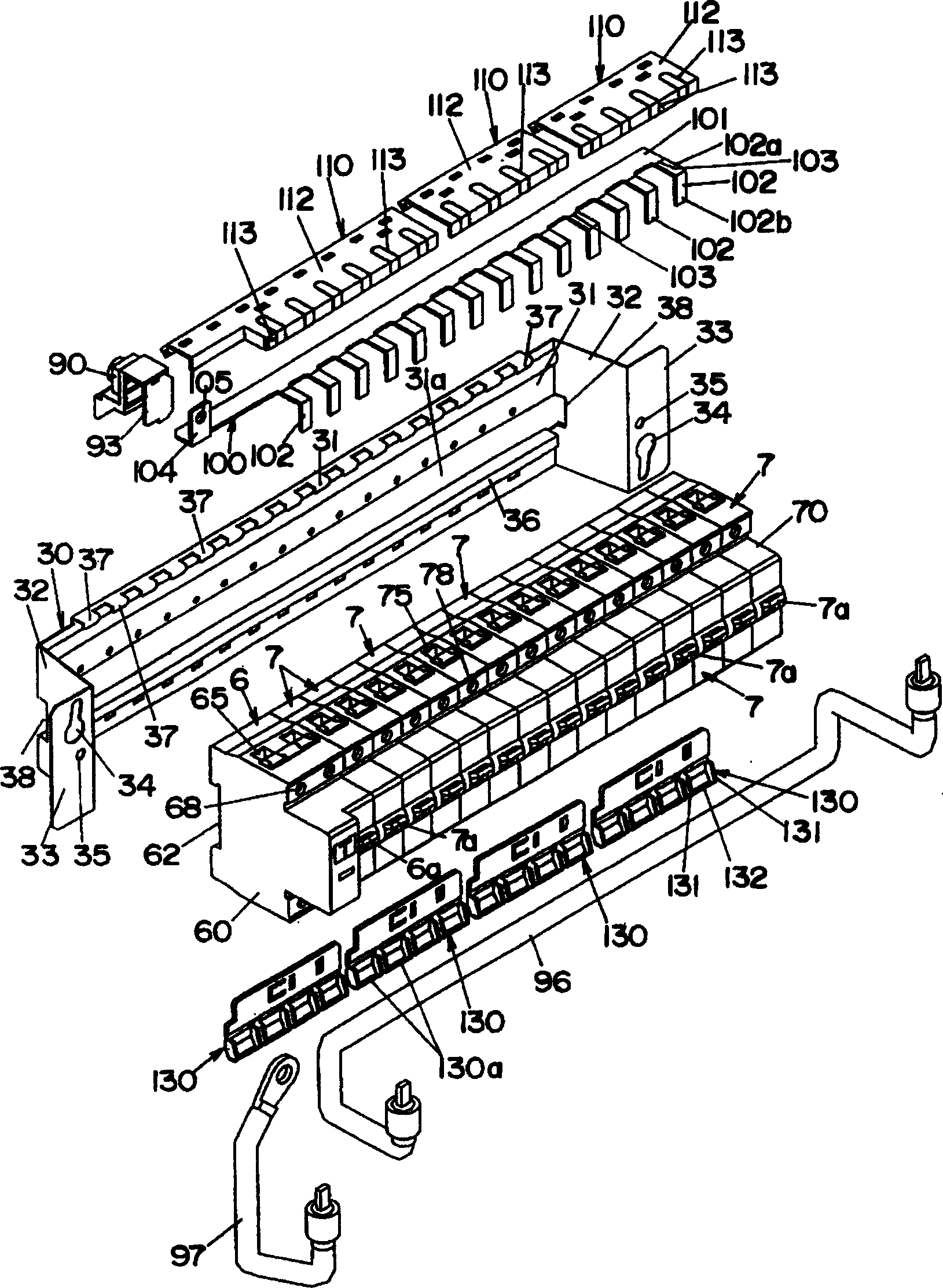

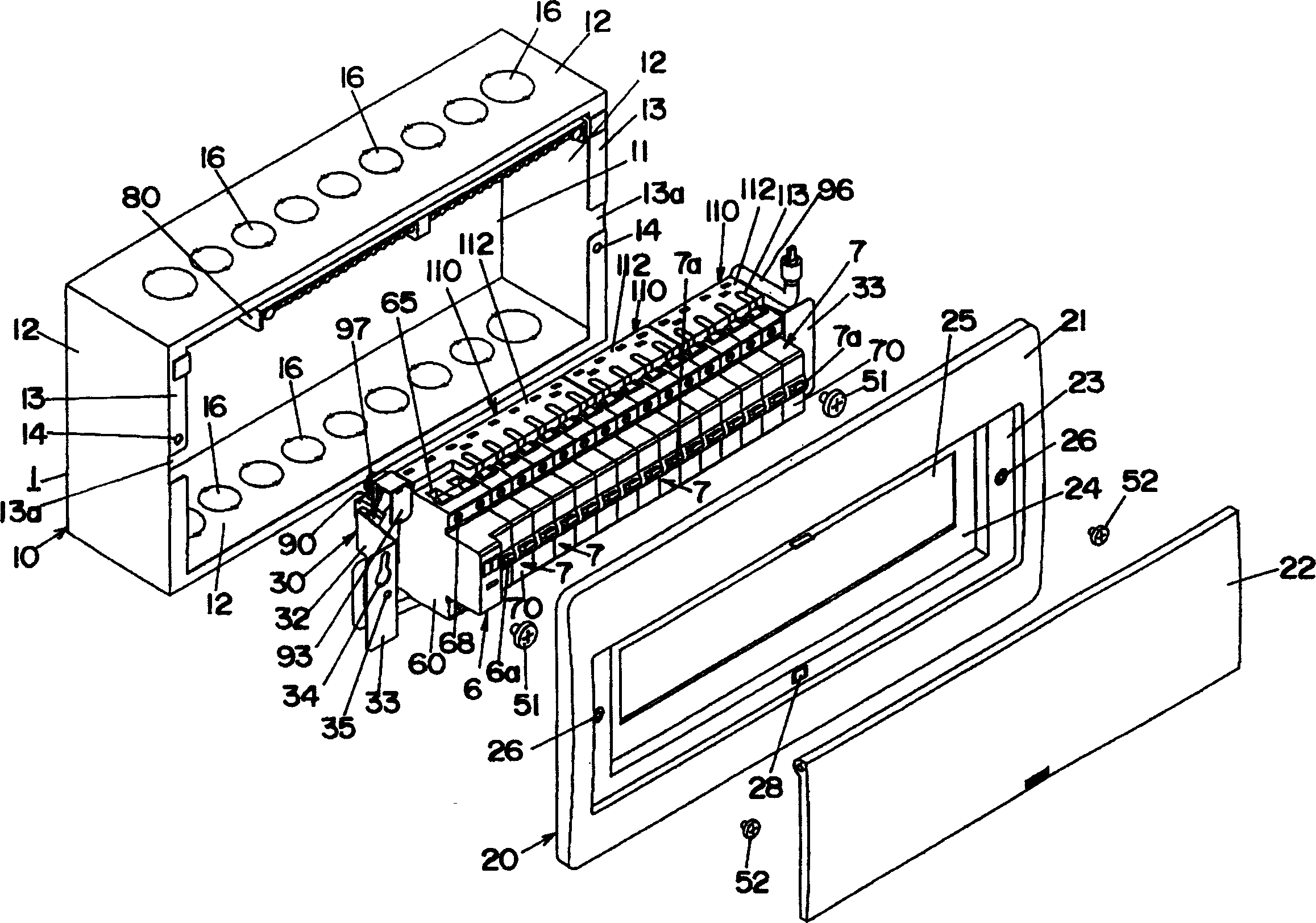

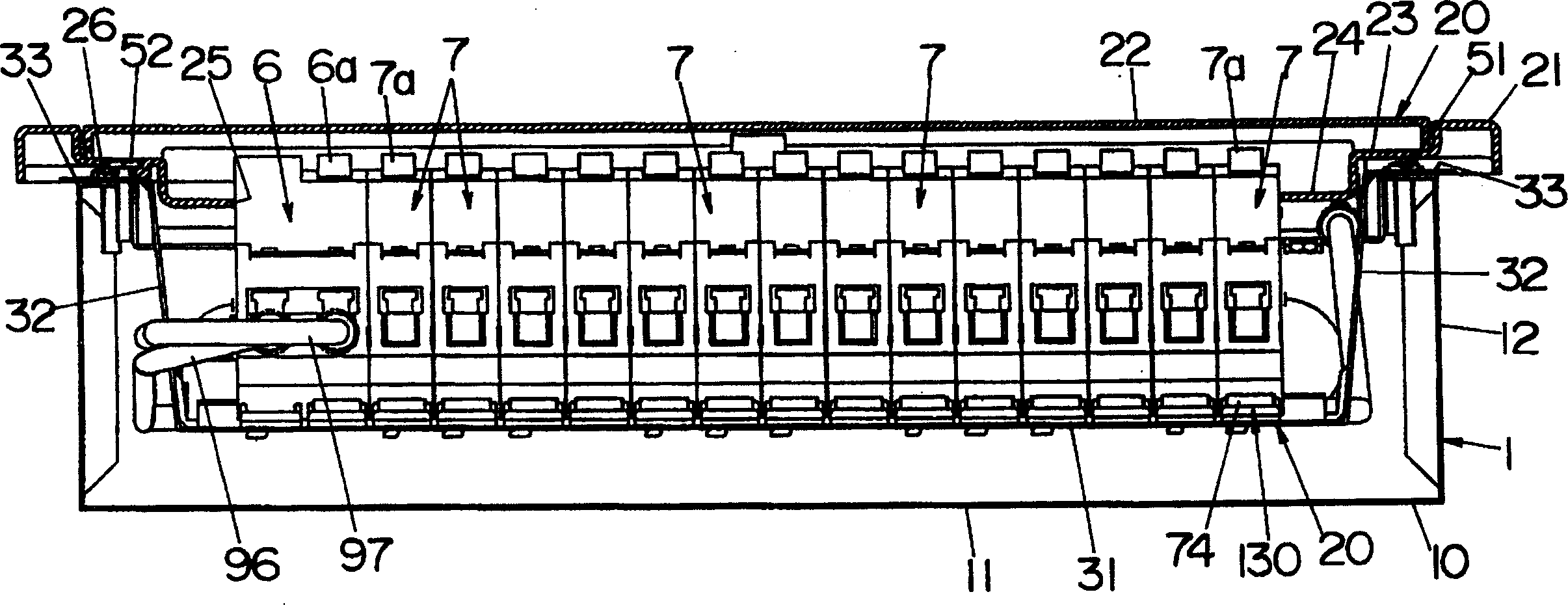

[0029] Below, see Figure 1 to Figure 14 , to illustrate the switchboard of this embodiment.

[0030] Make the switchboard of this embodiment, as figure 2 As shown in FIG. 4 , a main circuit breaker 6 and a plurality of branch circuit breakers 7 are arranged in the box body 1 as internal bodies. The main circuit breaker 6 and the plurality of branch circuit breakers 7 are arranged in a row in the short side direction. The box body 1 is composed of a box body 10 made of metal with an open front, and a cover body 20 joined to the box body 10 so as to close the opening of the box body 10 . In addition, the box body 10 is embedded in a wall surface such as a wall.

[0031] The box body 10 is composed of a rectangular rear panel 11 and side panels 12 provided forward from the periphery of the rear panel 11 . From the front edges of the left and right side plates 12 , supporting pieces 13 , 13 are extended in a direction approaching each other, and screw holes 14 , 14 are forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com