Air blast cooling rotary vane roller pump

A technology of cold rotary vane and roller pumps, applied in the field of variable capacity pumps, can solve the problems of direct-coupled pumps such as temperature rise, large frictional resistance, and large power consumption, and achieve the goals of increasing ultimate vacuum, reducing temperature rise, and reducing power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

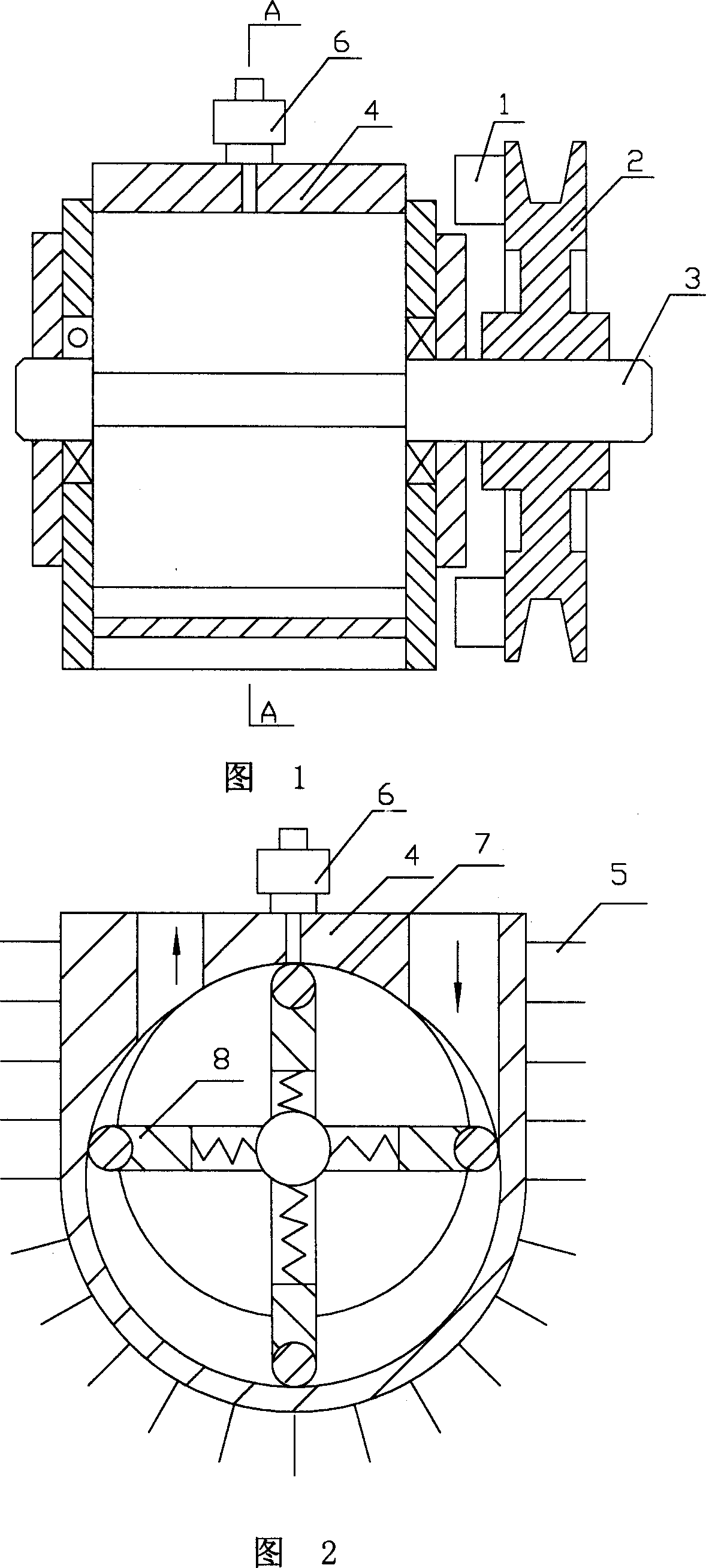

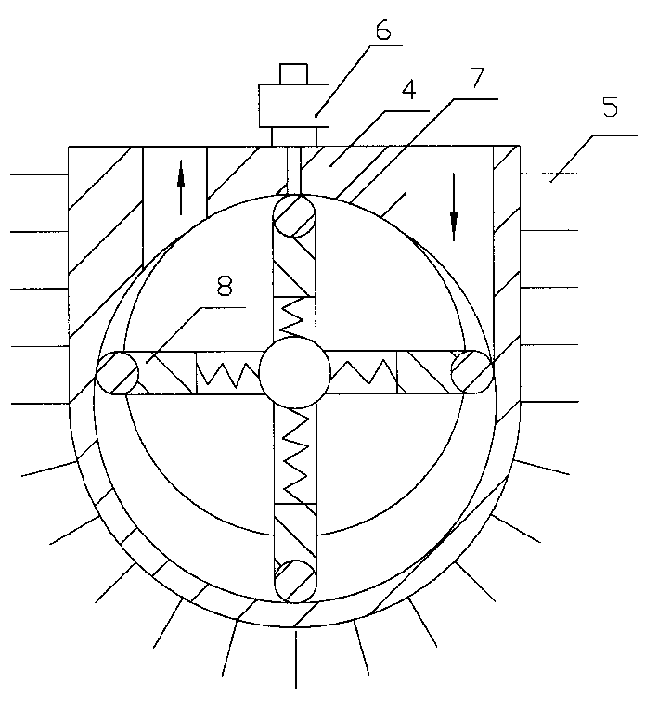

[0031] Process a small circular arc (7) equal to the rotor radius in the single cylindrical hole of the pump body cavity, and the length of the small circular arc is advisable to eliminate the harmful space of the rotor body and the pump. A needle valve type drip cup (6) is installed on the pump body (4) to regulate the oil intake, to ensure the lubrication in the pump, but the pump does not inject oil. A pulley (2) is installed on the rotor shaft (3) of the pump, a number of vanes (1) are cast on the rim end surface of the pulley, and axial cooling fins (5) are cast on the outer surface of the pump body. When the pulley rotates, the blades Forced air cooling of the pump body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com