Oil leading-out cooling structure of large-pumping-speed rotary vane pump

A cooling structure and technology of rotary vane pumps, which are applied in the sealing device of piston pumps, components of pumping devices for elastic fluids, rotary piston type/oscillating piston type pump components, etc., and can solve unsatisfactory cooling effects, etc. problem, to achieve the effect of easy structure, remarkable effect, and ultimate vacuum degree improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following examples are intended to illustrate the present invention, but not to limit the scope of the present invention.

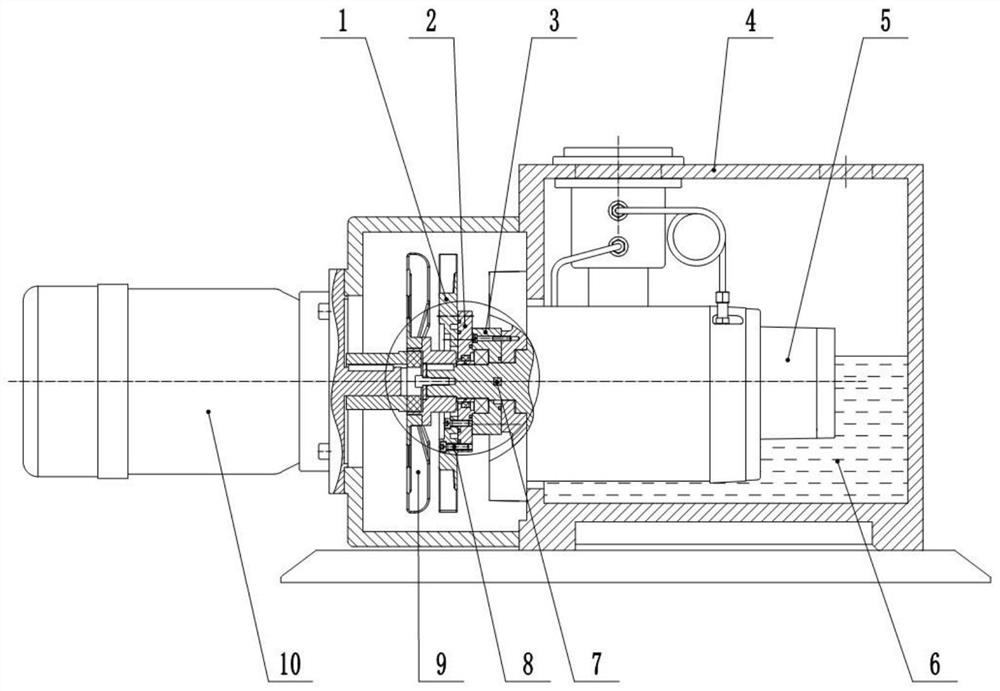

[0042] An oil extraction cooling structure of a high pumping speed rotary vane pump, the high pumping speed rotary vane pump includes a motor 10, an oil tank 4 and a pump core 5, and the pump core 5 includes a rotor, an oil pump rotary vane 7 and other components;

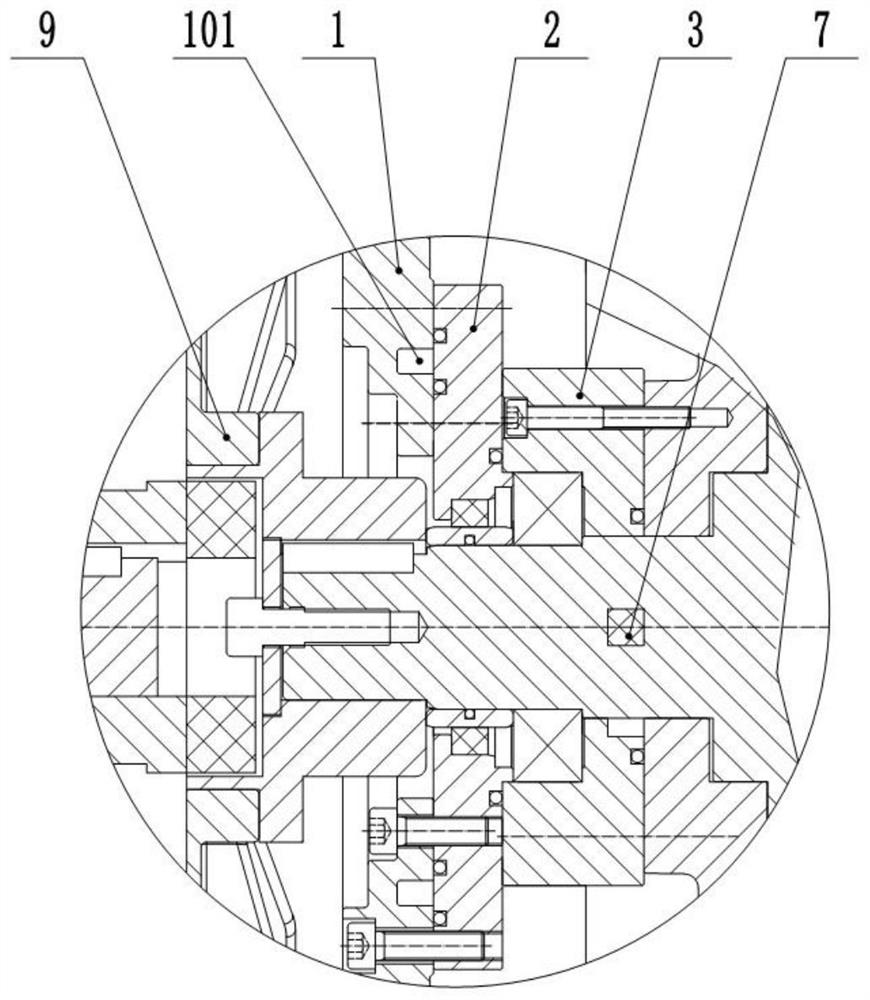

[0043] The extended end of the rotor is mounted on the bearing seat 3 through a bearing, and an oil pump groove is provided in the center of the pump core side of the bearing seat 3 for the rotation of the oil pump rotary vane 7; the other side of the bearing seat 3 is sealed and connected The bearing gland 2, the other side of the bearing gland 2 is sealed and connected to the oil cooling fin 1;

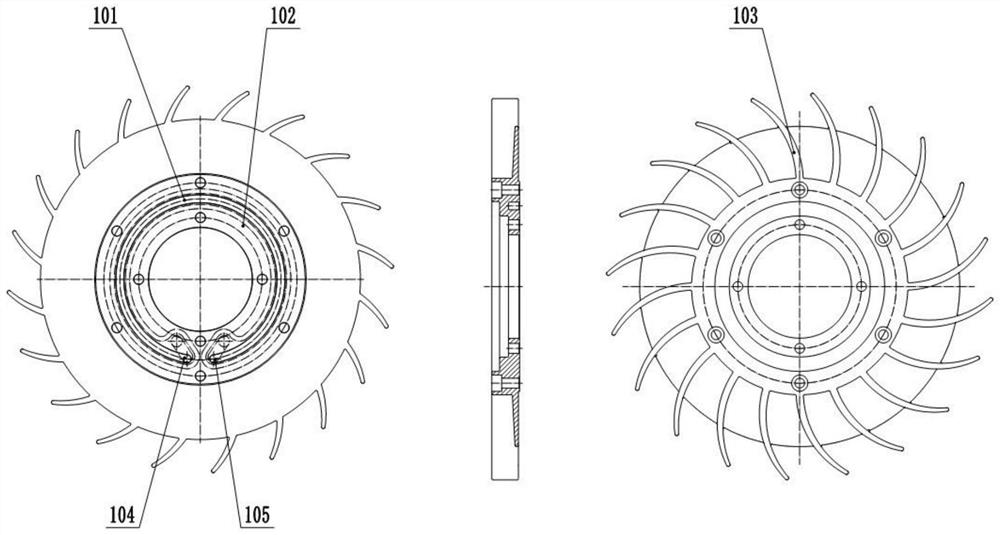

[0044] Wherein, a C-shaped oil groove 101 is provided on one side of the oil cooling fin 1 connected to the bearing press cover 2; a fan 9 is installed on the other side of the oil coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com