Single-stage and double-stage switching rotary vane vacuum pump

A rotary vane vacuum pump, single- and double-stage technology, applied in the field of single- and double-stage switching rotary vane vacuum pumps, can solve the problems of increasing customer use costs and inability to switch to use, and achieve the effect of improving space utilization, compact structure, and improving vacuum degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

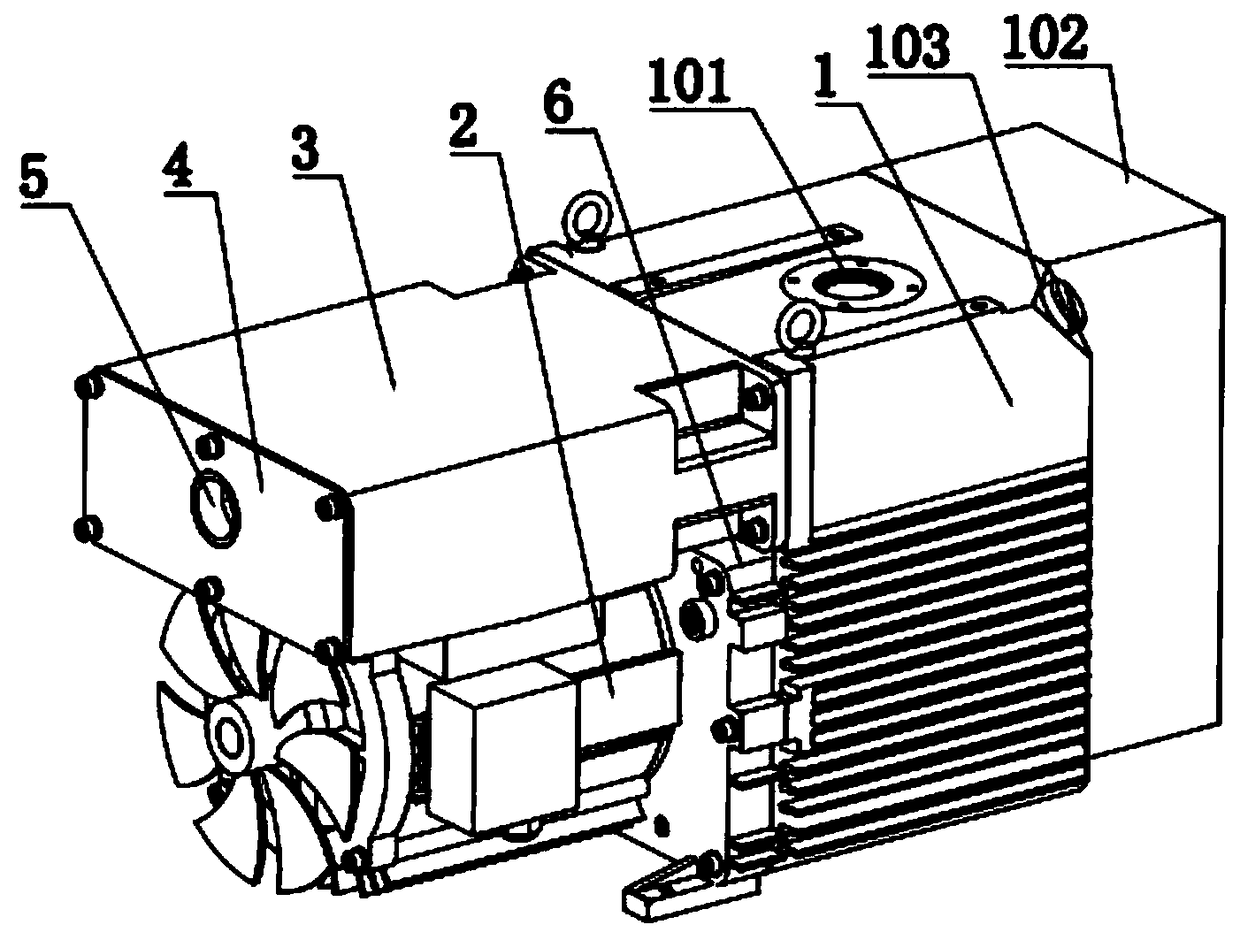

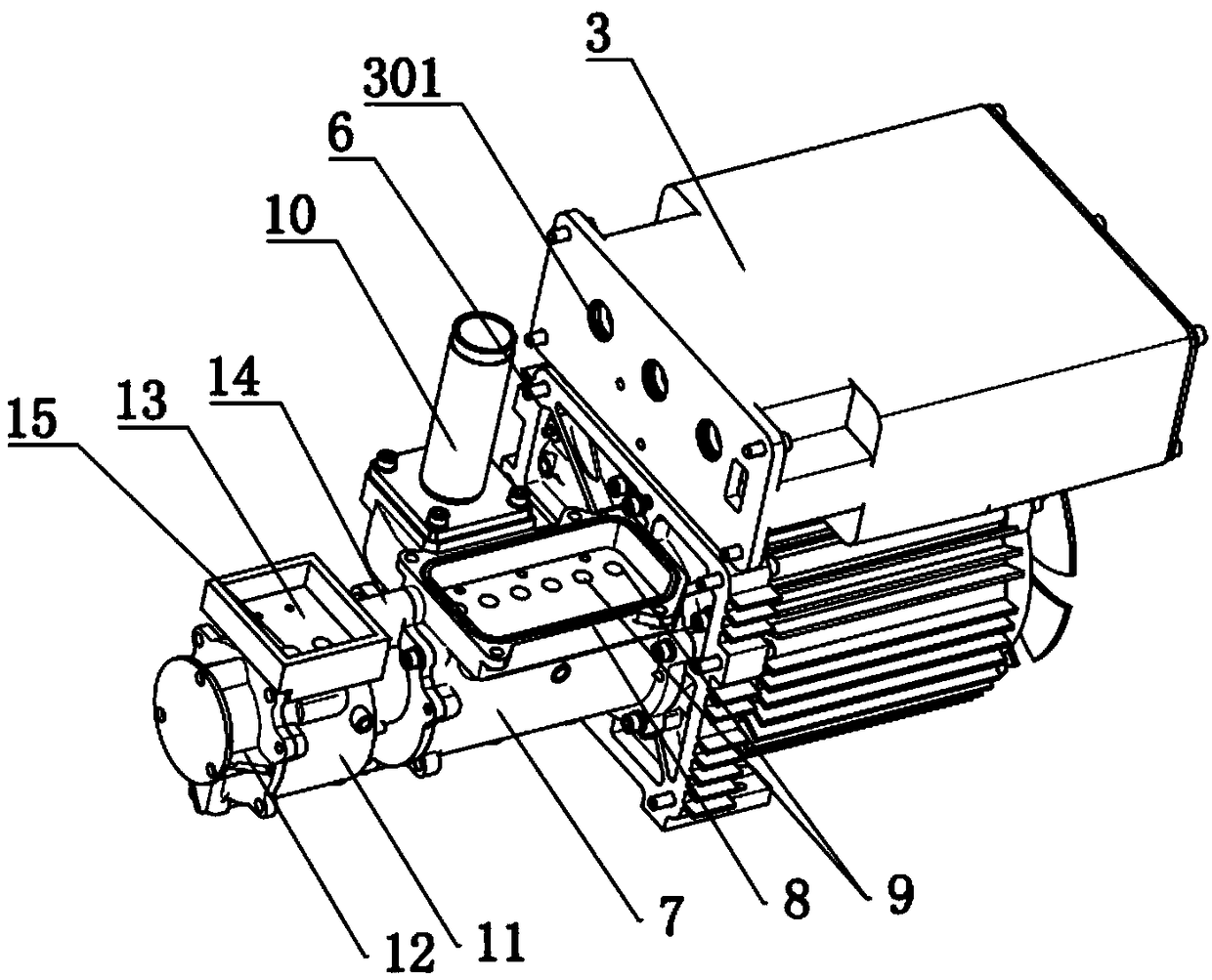

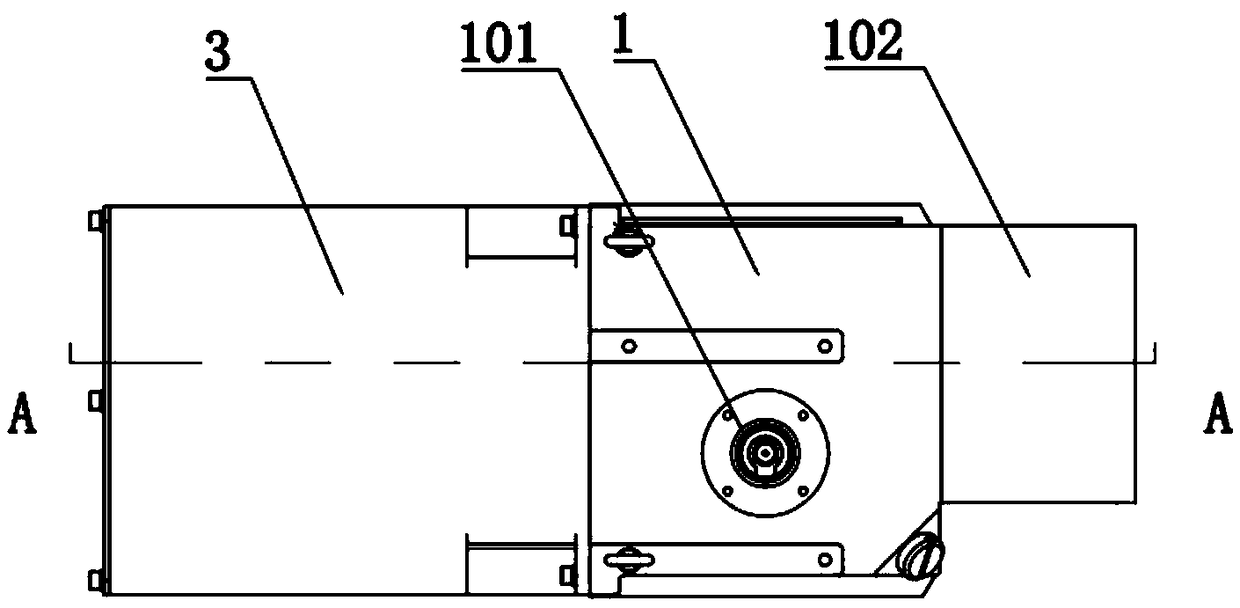

[0030] A single and double stage switching rotary vane vacuum pump, reference Figure 1-Figure 5 , Including an oil tank 1, a first pump body 7 arranged in the oil tank 1, a front end cover 12 and a rear end cover 6 at both ends of the first pump body 7, a first rotor 702 eccentrically arranged inside the first pump body 7, the first There are more than two first rotary vanes on the rotor 702. In this embodiment, there are 3 first rotary vanes. The first suction port 10 and the first exhaust port 9 are provided on both sides of the upper end of the first pump body 7. , The oil tank 1 is provided with a suction port 101, the end of the first suction port 10 away from the first pump body 7 is welded to the suction port 101 or fixedly connected by a flange, and the bottom of the first pump body 7 is provided with the first pump body 7 The first pumping hole 701 of the pump cavity, the first exhaust valve is provided in the first exhaust port 9, the upper end of the first pump body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com