Maturing method of edible vinegar and its equipment

A vinegar aging technology, applied in the field of aging vinegar by physical means, can solve the problems of unpopular equipment, high manufacturing requirements, inconvenient continuous production, etc., and achieve the effects of shortening the production cycle, improving quality, and good application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

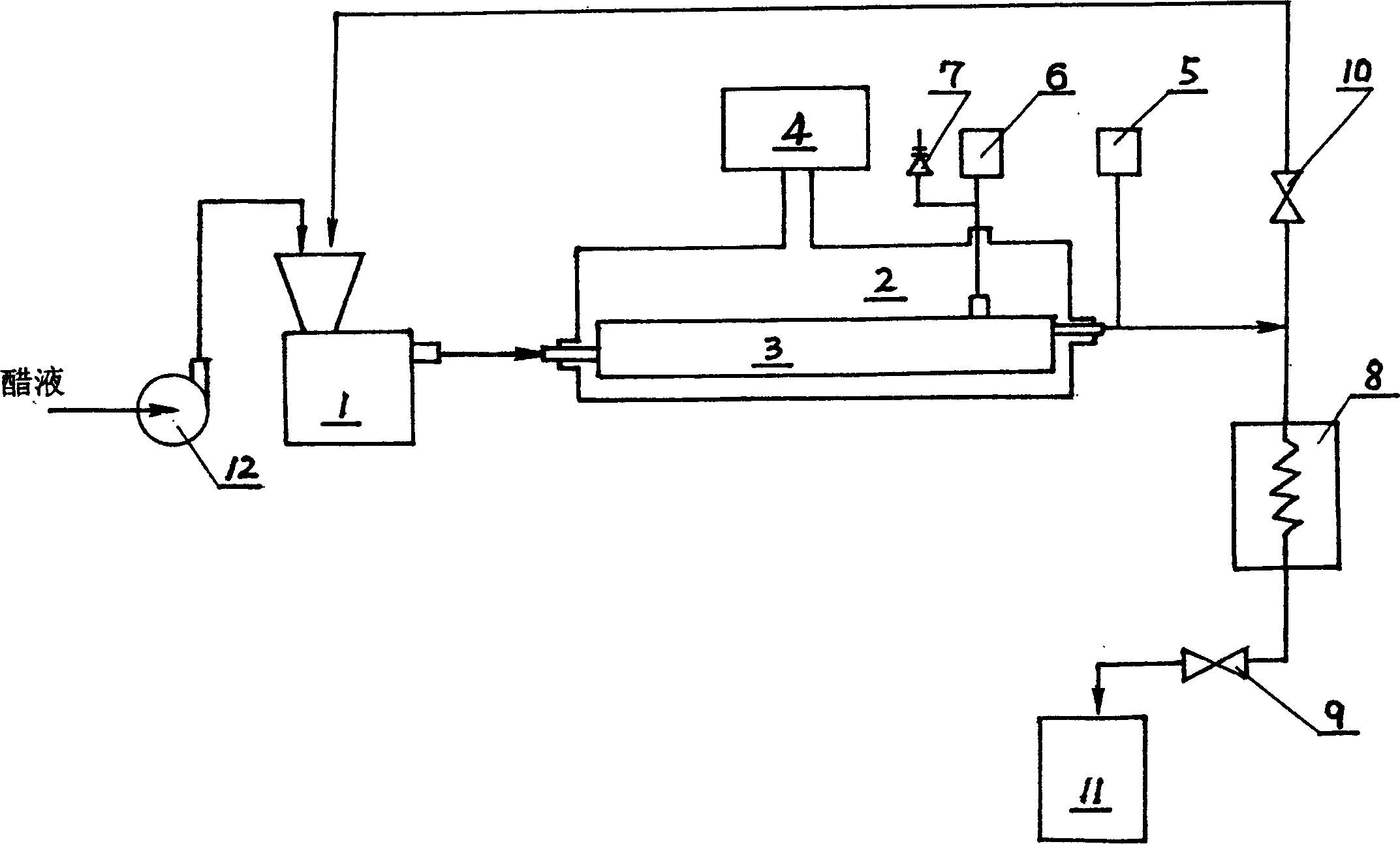

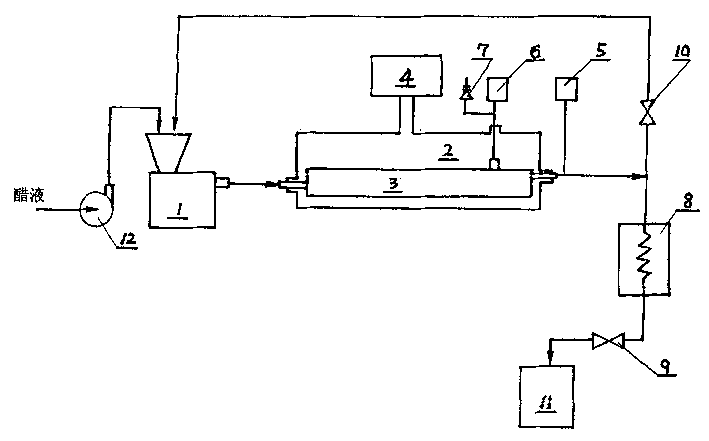

Method used

Image

Examples

Embodiment 1

[0021] Example 1 After the brewed vinegar with a total ester content of 3.28% is homogenized by a 20MPa high-pressure homogenizer (the pressure of the first-stage homogenizing valve is 12MPa, and the pressure of the second-stage homogenizing valve is 5Mpa), it immediately flows into the vinegar with a gauge pressure of Microwave radiation is used in the microwave reactor of 0.02Mpa. After the temperature reaches 82°C, it flows into the cooler. After decompression and cooling to 35°C, the product is collected. The total acid content is 4.03%, the total ester content is 4.30%, and the total ester content increases. The rate is 31.10%.

Embodiment 2-5

[0022] Embodiment 2-5 The method is the same as that of Embodiment 1, and the experimental data are shown in Table 1.

[0023] Reality

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com