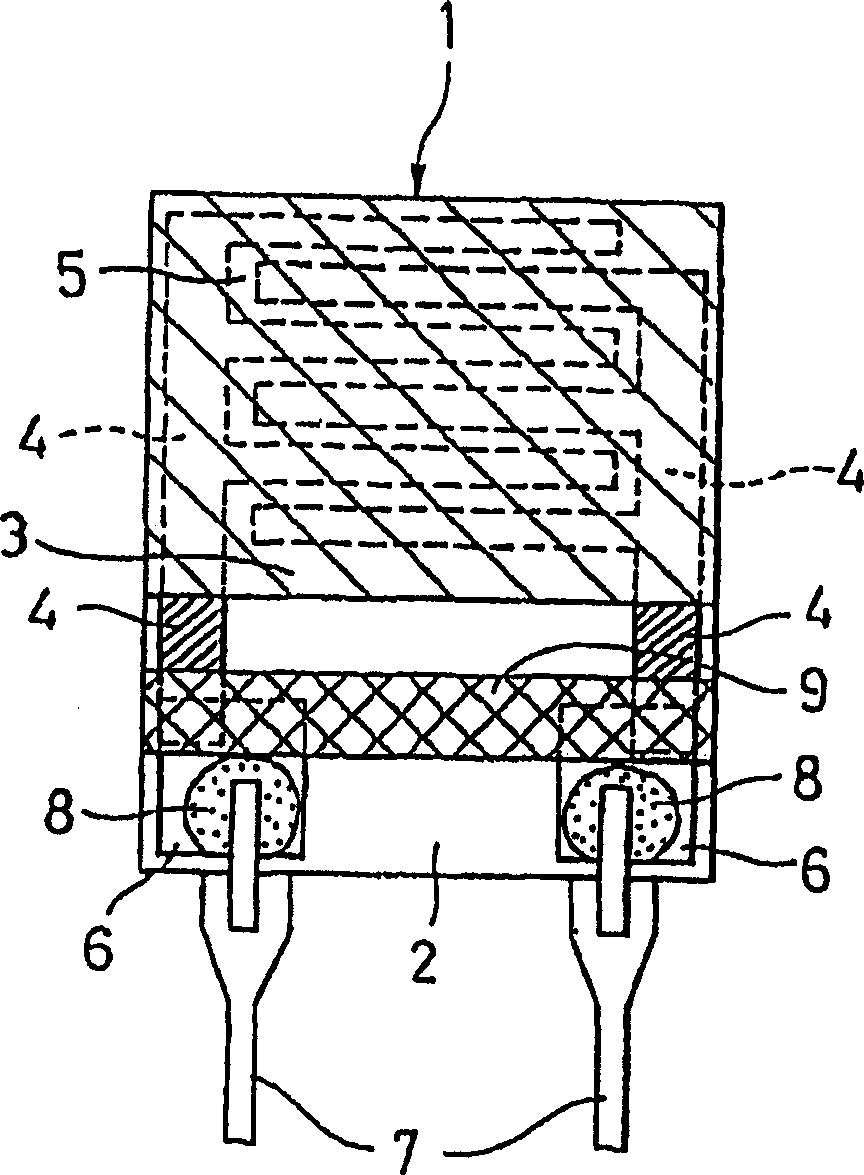

Humidity sensor element and method for manufacture thereof

A technology of humidity sensor and manufacturing method, which is applied in the direction of instruments, scientific instruments, measuring devices, etc., and can solve problems such as substrate peeling and cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0372] First, the monomer of formula (2) is synthesized.

[0373] Make N, N, N: N'-tetramethyl-1,12-dodecanediamine 3.62g (21.0mmol) and 1,12-dibromododecane 6.92g (21.1mmol) in 20.2g of methanol The reaction was carried out at 110°C for 48 hours, and 9.04 g of white precipitate was reprecipitated with acetone. Then, 6.92 g of white precipitates and 3.54 g of dimethylaminopropylmethacrylamide were reacted in methanol at 90° C. for 24 hours, and reprecipitation was repeated in acetone to obtain 5.47 g of pale yellow precipitates. The number average molecular weight is about 5000.

[0374] Next, the monomer of formula (1) was synthesized.

[0375] 11.82 g (75.2 mmol) of dimethylaminoethyl methacrylate and 4.23 g (37.4 mmol) of 1,3-dichloropropane were dissolved in 21.04 g of acetonitrile, and 4-methoxyphenol was added as a polymerization inhibitor After 0.27 g, react at 60° C. for 120 hours, and reprecipitate with 1000 ml of acetone to obtain 17.52 g of quaternary ammonium sa...

Embodiment 2

[0390] In the same way as in Example 1, an aluminum oxide substrate with a comb-shaped electrode is made in advance, and 1% (mass percent) acetic acid aqueous solution of γ-methacryloxypropyltrimethoxysilane (KBM503 manufactured by Shin-Etsu Chemical) is used After drying, place it at 120°C for 20 minutes to introduce acryloyl groups on the surface of the substrate. Then, it was dipped in the same moisture-sensitive film-forming monomer liquid as in Example 1 to form a coating film. Then, similar to Example 1, ultraviolet rays were irradiated, polymerized, and cross-linked to obtain a humidity sensor element.

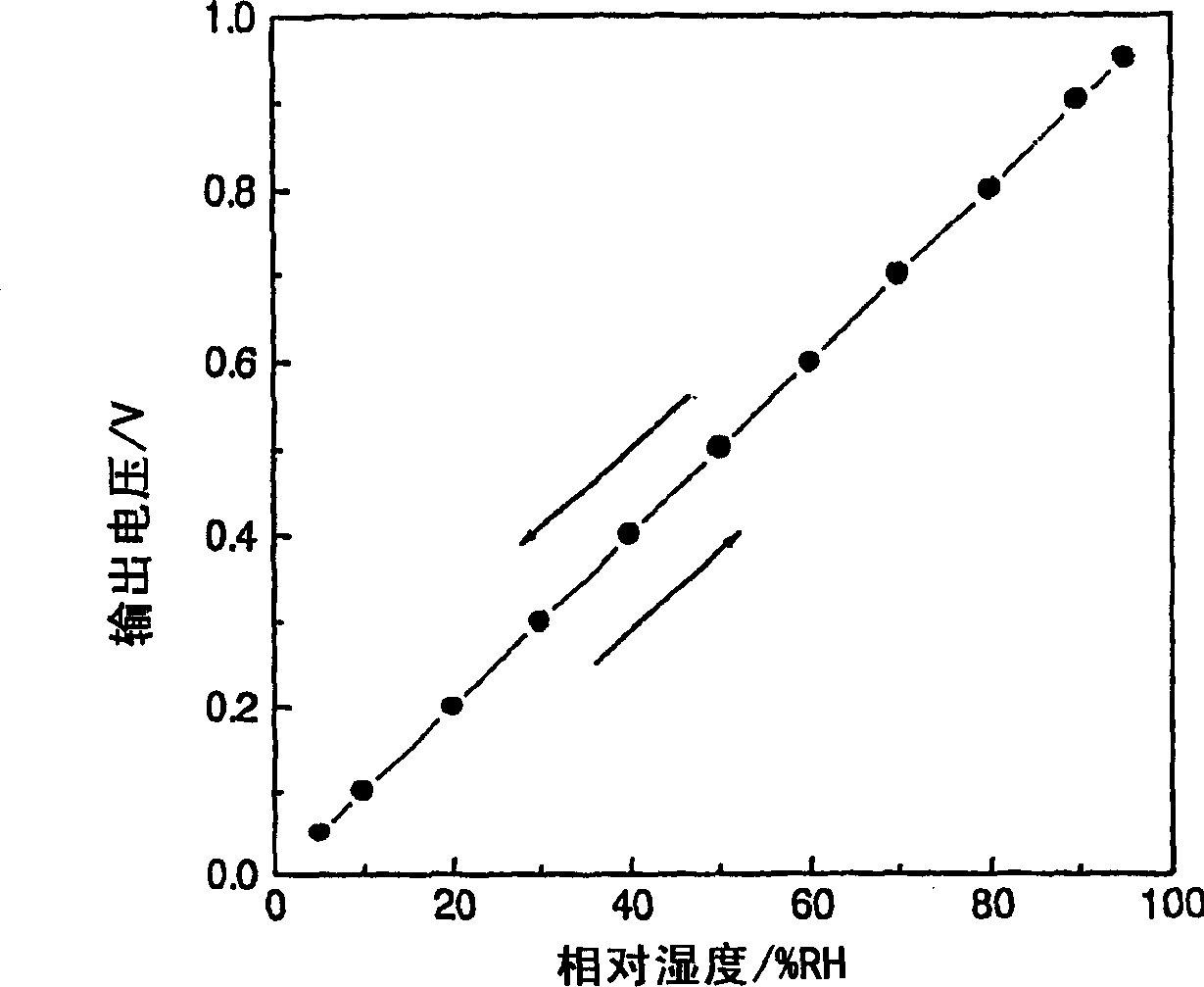

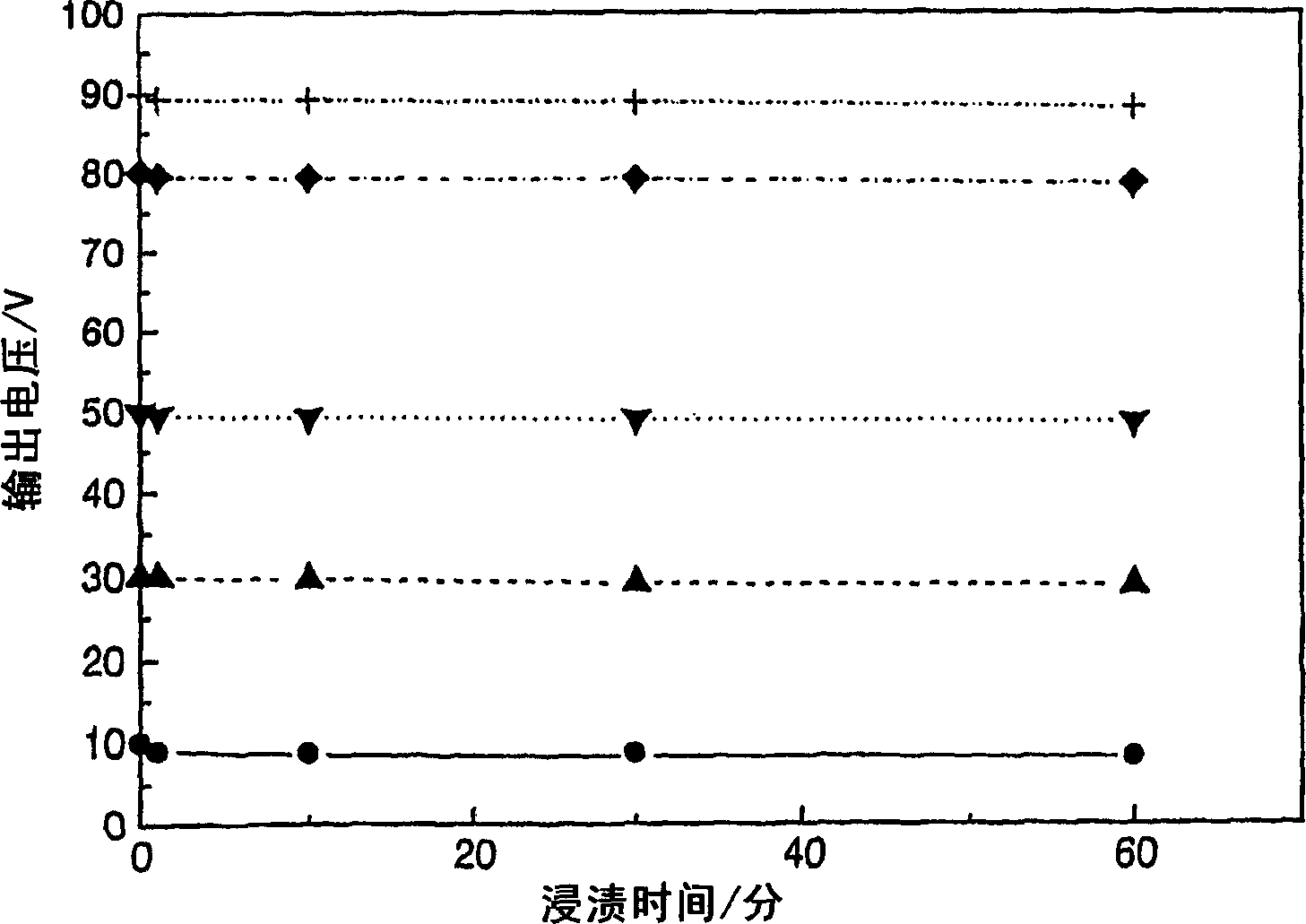

[0391] The evaluation of the output characteristics of the humidity sensor element thus obtained and the water resistance test were carried out in the same manner as in Example 1. The obtained output characteristics were measured as Figure 4 As shown, the water resistance test results are as follows Figure 5 shown.

[0392] Figure 4 and Figure 5 The results sh...

Embodiment 3

[0395] First, the monomer of formula (2) is synthesized.

[0396] Dissolve 6.30g (36.6mmol) of N,N,N',N'-tetramethyl-1,12-dodecanediamine and 9.62g (40.2mmol) of 1,12-dichlorododecane in 23g of In methanol, reflux in an eggplant-shaped flask. The temperature of the oil bath at this time was 110°C. After 36 hours of reaction, it was confirmed that the solution became cloudy white. After 48 hours, the reaction was stopped, and 40 ml of methanol was added to the white viscous solution. There was no insoluble matter, but after filtering once, a white precipitate was obtained through repeated re-precipitation operations. The amount of acetone used was 500ml. The weight after drying was 6.04 g. Then, 5.07 g of the white precipitate was dissolved in 9 g of methanol. Further, 2.98 g of dimethylaminopropyl methacrylamide was added thereto, and the temperature of the oil bath was 90° C., and the reaction was carried out for 24 hours. The solution is dark orange viscous. 20 ml of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com