Copper base alloy with improved punchin and impacting performance and its preparing method

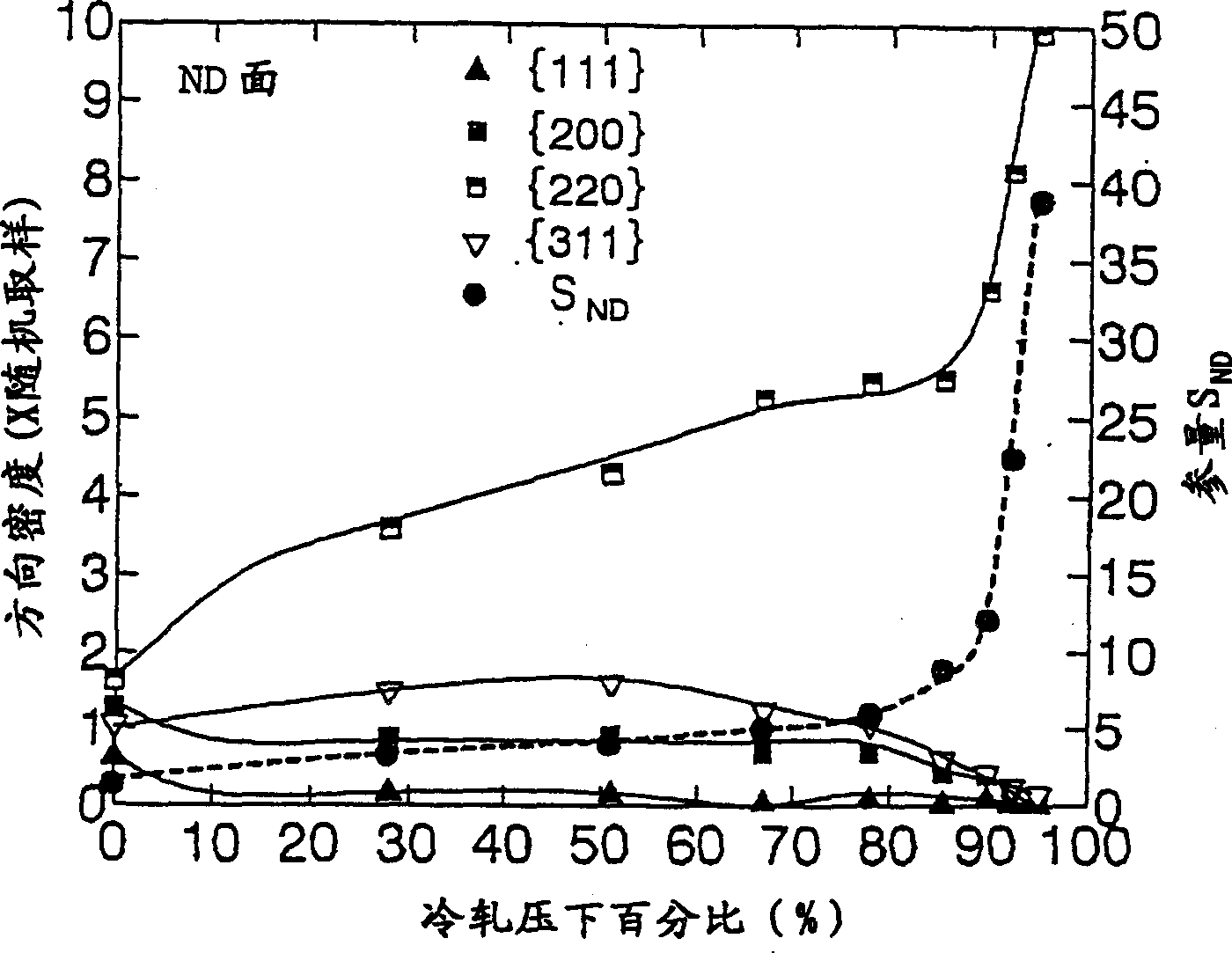

A copper-based alloy, alloy technology, applied in 0}/I{, the preparation of the alloy, the copper-based alloy with stamping and punching properties, the SND is at least 10 [SND field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] In an argon atmosphere, copper-based alloy samples No. 1-4, No. 6-9 and No. 11-16 having the chemical composition analysis results (% by weight) shown in Table 1 were melted and cast in a vertical continuous casting machine An ingot with a size of 20mm×80mm×1000mm was formed. The obtained ingot was subjected to a homogenization heat treatment at 900° C. for 1 hour. Afterwards, the ingots (numbers 1-4, 6-9 and 11-16) were hot rolled from 20 mm to 6.0 mm in thickness, quenched with water and pickled. The 6.0mm thick sheets were cold rolled to various thicknesses: 2.5mm for samples numbered 1, 7 and 8; 2.0mm for samples numbered 2, 3 and 16; 2.0mm for samples numbered 4, 6 and 15 The thickness of the sample is 1.0mm; the thickness of the sample numbered 9 is 3.5mm; the thickness of the sample numbered 11 is 0.6mm; the thickness of the sample numbered 12 is 0.5mm; the thickness of the sample numbered 13 is 0.3mm; mm.

[0060] Copper-based alloy samples having the chemica...

Embodiment 2

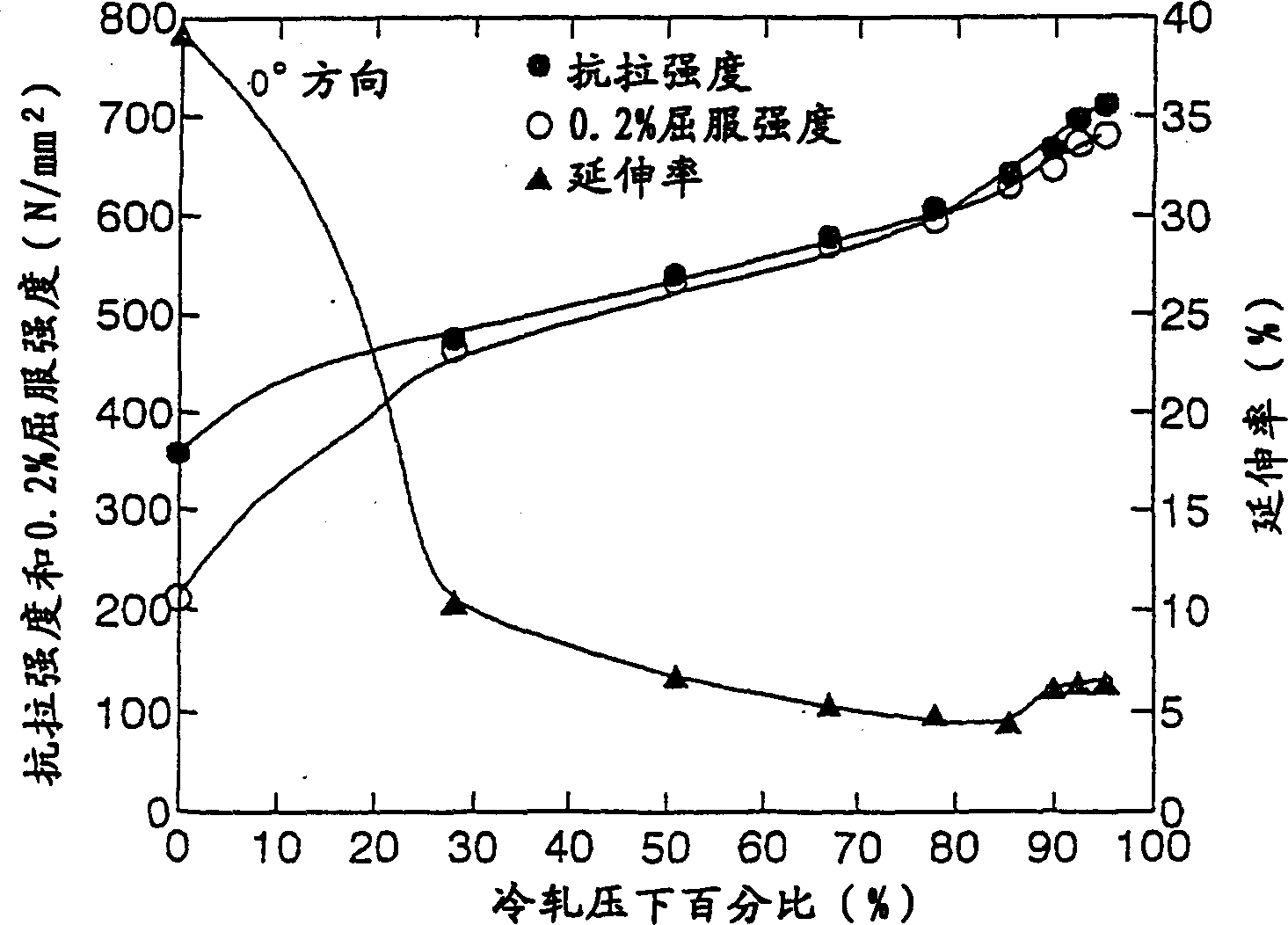

[0068] For sample alloy No. 1 according to the present invention (see above Table 1; plate thickness 0.20mm), industrial phosphor bronze alloy (C5191; state, H; plate thickness, 0.20mm; 6.5% by weight Sn, 0.2% by weight P, the rest is Cu) and industrial copper-based alloy (C7025; state, H; plate thickness, 0.20mm; 3.2% by weight Ni, 0.70% by weight Si, 0.15% by weight Mg, and the rest is Cu) electrical conductivity, 0.2% yield strength, Spring deflection limit, Vickers hardness, press workability and bending properties were evaluated.

[0069] conductivity

(%IACS)

0.2% yield strength

(N / mm 2 )

0° direction

90° direction

elastic deflection limit

(N / mm 2 )

0° direction

90° direction

Vickers hardness

(HV)

Maximum punch

Number of times

(×10 4 )

R / t * the smallest

value

0° direction

90° direction

The present invention

Gold No. 1 sample

40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com