Composite wall insulative materials

A thermal insulation material and composite wall technology, which is applied in the field of building exterior wall insulation and roof insulation, can solve the problems of expensive raw materials, difficult packaging and transportation, and large indoor space, and achieve low price, non-deterioration, and improved economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

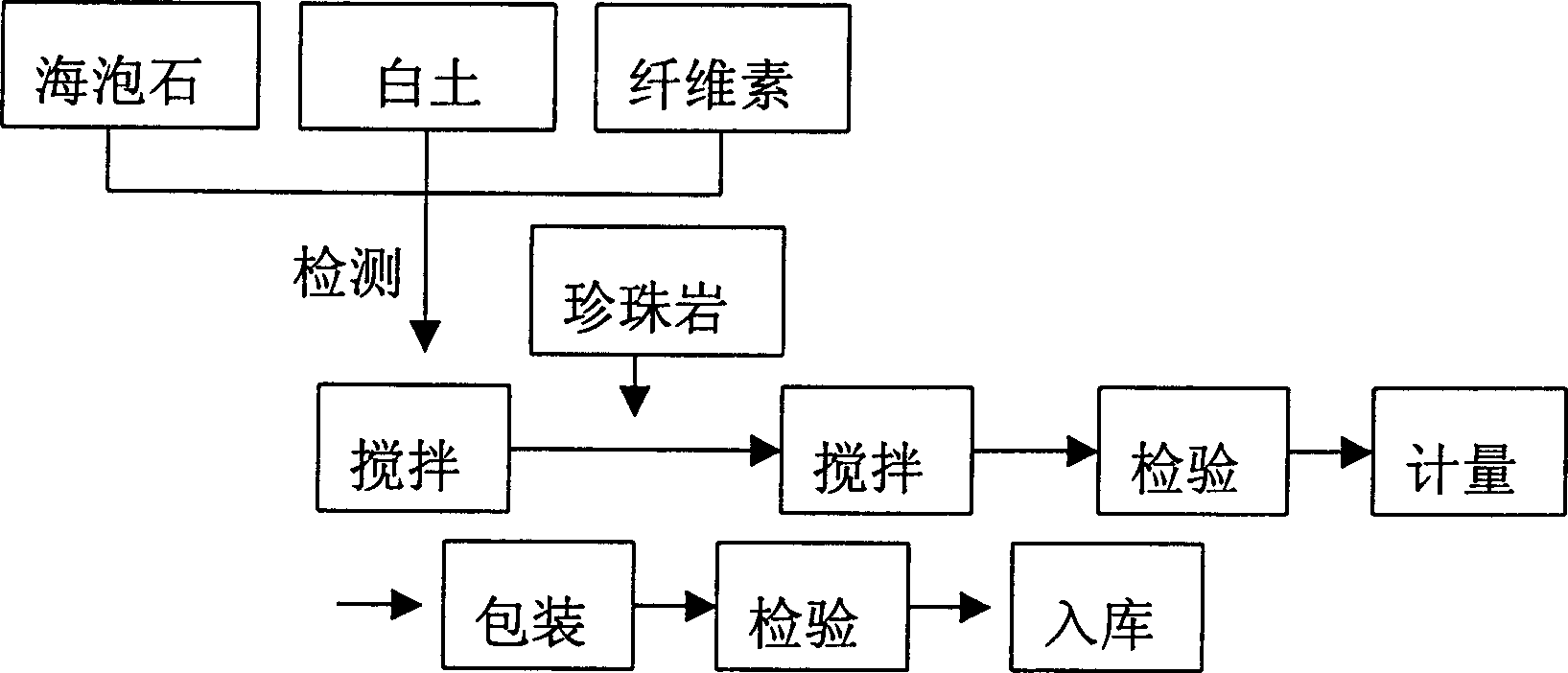

[0023] Take 110 parts of sepiolite powder, 44 parts of perlite, 35 parts of white clay and 12 parts of cellulose by weight.

[0024] Stir the sepiolite, white clay, and cellulose in a mixer for 5 minutes, then add perlite and stir for 2 to 3 minutes. When using, add two parts of water to one part of dry powder by weight, and it will form a mortar after mixing, which can be directly applied to the wall.

example 2

[0026] 105 parts of sepiolite powder, 45 parts of perlite, 33 parts of white clay, 14 parts of cellulose, the processing method is as above example.

example 3

[0028] 115 parts of sepiolite powder, 45 parts of perlite, 32 parts of clay, 15 parts of cellulose, the processing method is as above example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com