Reinforcing air intake valve for diesel engine of diesel locomotive and its manufacture

A technology for internal combustion locomotives and diesel engines, which is applied in the field of intake valves, can solve problems such as performance that cannot meet the working requirements, affect the service life of the valve, and cannot meet the service life, etc., and achieve excellent performance, extended maintenance period, and improved wear-resistant life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

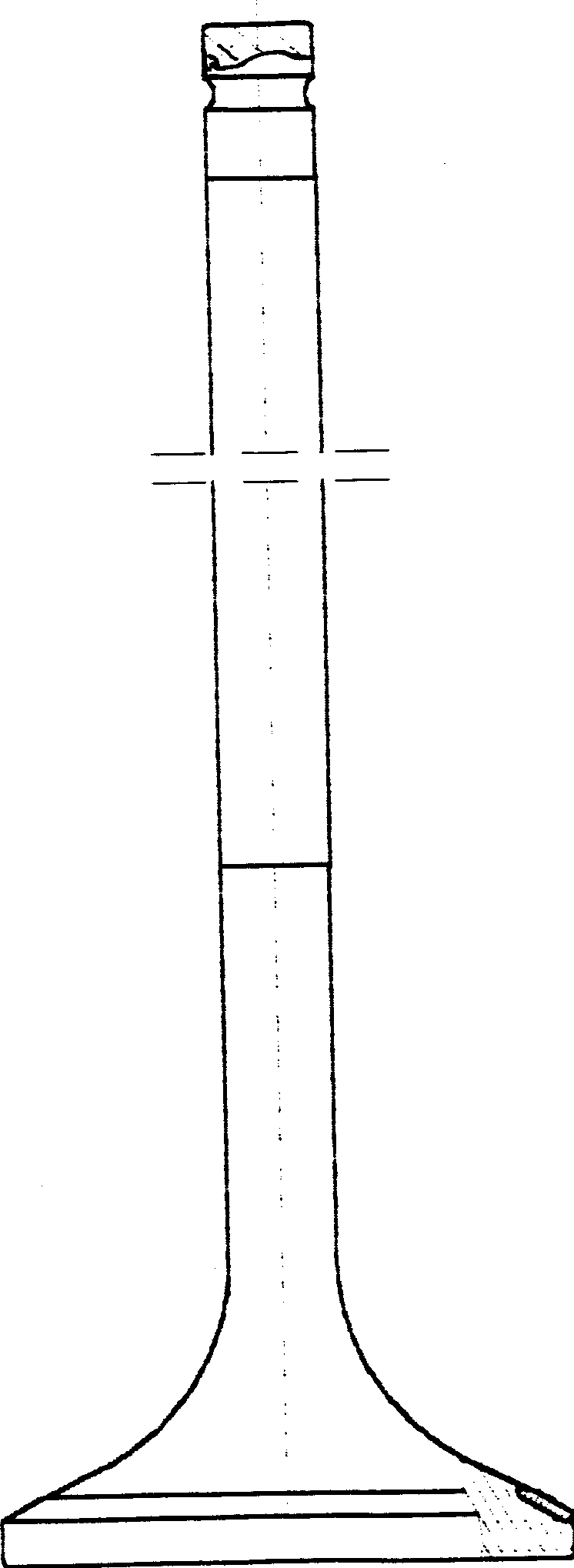

Image

Examples

Embodiment 1

[0022] The manufacturing material of the highly strengthened intake valve of the diesel engine of the diesel locomotive of the present invention is strengthened strong martensitic steel MS41, and its chemical composition specification (wt%) can be selected as: C: 0.35 / 0.4; Si: 2.5 / 2.6; Mn: 0.45 / 0.6; Ni≤0.50; Cr: 10 / 10.5; S≤0.002; P≤0.003; Mo: 0.25 / 0.3; the rest is Fe.

Embodiment 2

[0024] The manufacturing material of the high-strengthened intake valve for diesel locomotive engine of the present invention is strengthened strong martensitic steel MS41, and its chemical composition specification (wt%) can be selected as: C: 0.4 / 0.45; Si: 2.6 / 2.8; Mn: 0.35 / 0.45; Ni≤0.50; Cr: 8.5 / 9.5; S≤0.002; P≤0.003; Mo: 0.3; the rest is Fe.

Embodiment 3

[0026] The manufacturing material of the highly strengthened intake valve of the diesel engine of the diesel locomotive of the present invention is strengthened strong martensitic steel MS41, and its chemical composition specification (wt%) can be selected as: C: 0.4 / 0.5; Si: 2.9 / 3.6; Mn: 0.35 / 0.4; Ni≤0.50; Cr: 9.5 / 10.5; S≤0.002; P≤0.003; Mo: 0.2 / 0.25; the rest is Fe.

[0027] Under the chemical composition ratio of any of the above-mentioned embodiments, the manufacturing method of the high-strength intake valve for diesel locomotive diesel engine is: material preparation→valve blank electrothermal upsetting forming→heat treatment→machining

[0028] 1. Material preparation: cut the polished bar into a fixed length, and make a specific R at the deformed end

[0029] 2. Electrothermal upsetting of valve blanks: During electrothermal upsetting, the forming temperature of valve bulbs is 1050°C-1100°C, the deformation speed of bulbs is 1.5-2mm / s, and the initial forging temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com