Upholder with multiple materials layers in field emission flat panel displays

A flat-panel display device and field emission technology, applied in electroluminescent light sources, instruments, electrical components, etc., can solve problems such as troublesome operation, difficult application, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

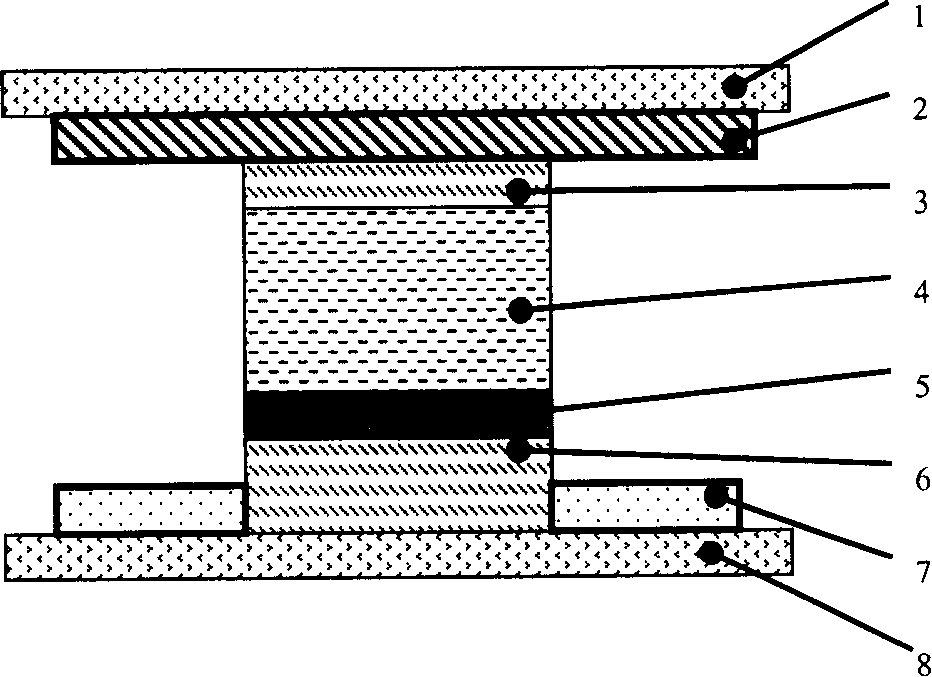

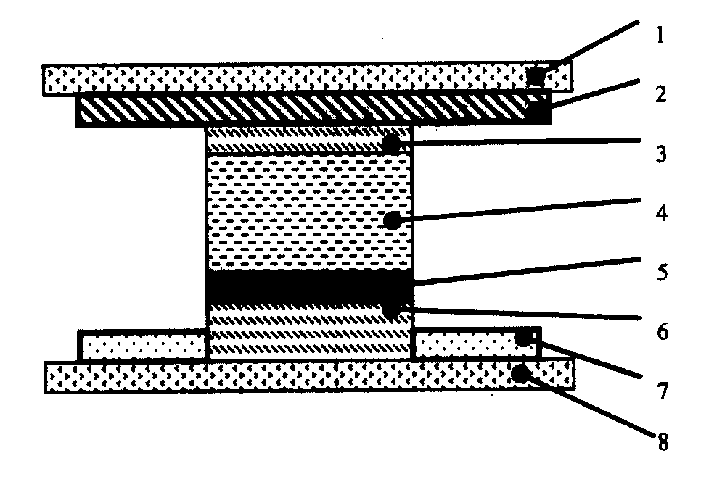

[0014] Such as figure 1 As shown, a better support is needed between the anode substrate 8 and the cathode substrate 1 of the field emission display device. The best embodiment of the present invention is a support formed by multiple functional material layers, namely the insulating layer 6, the black matrix material layer 5, the getter material layer 4 and the insulating layer 3 overlapped in sequence, first in the anode strip 7 gaps A layer of insulating layer 6 is formed by coating, printing, coating or template method, which can be aluminum oxide, silicon dioxide, tantalum pentoxide, etc., so as to avoid short circuit or leakage between the black matrix material layer 5 and the anode strip. Then, print or coat a layer of black matrix material layer 5 on it, which can be graphite milk, etc., to eliminate the glare of the screen and improve the display contrast of the screen. The third layer of material layer is a non-evaporable getter material Layer 4, can be zirconium, va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com