Preparation of reagent-free ampoul immuno sensor and use thereof

A technology of immunosensors and reagents, applied in instruments, scientific instruments, biological testing, etc., can solve the problems of large sample consumption, cumbersome operation steps, and long analysis time, so as to simplify the operation steps, simplify the analysis system, and shorten the analysis time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Example 1: Preparation of CA125 immunosensor

[0035] Choose a disk-shaped planar glassy carbon electrode with a diameter of 4mm as the carrier material, and take CA125 as an example for embedding and fixing:

[0036] (a) Electrode polishing: Firstly, the surface of the electrode is polished with metallographic sandpaper, and then polished on the suede with 1.0, 0.3, and 0.05 μm γ-alumina slurry respectively, and then rinsed with secondary water, and the surface of the electrode is washed with 1 : 1 Ultrasonic cleaning with nitric acid, acetone, and secondary water to obtain a fresh and clean electrode surface.

[0037] (b) Electrode indication pretreatment: Electrolyze the polished electrode in a phosphate buffer solution with a pH value of 5.0 at a constant potential of +1.75V for 300 seconds, and then test it at +0.3V~+1.3V and +0.3V respectively Circular scanning within the potential range of ~-1.3V until a stable current value is obtained. The electrodes were ...

Embodiment 2

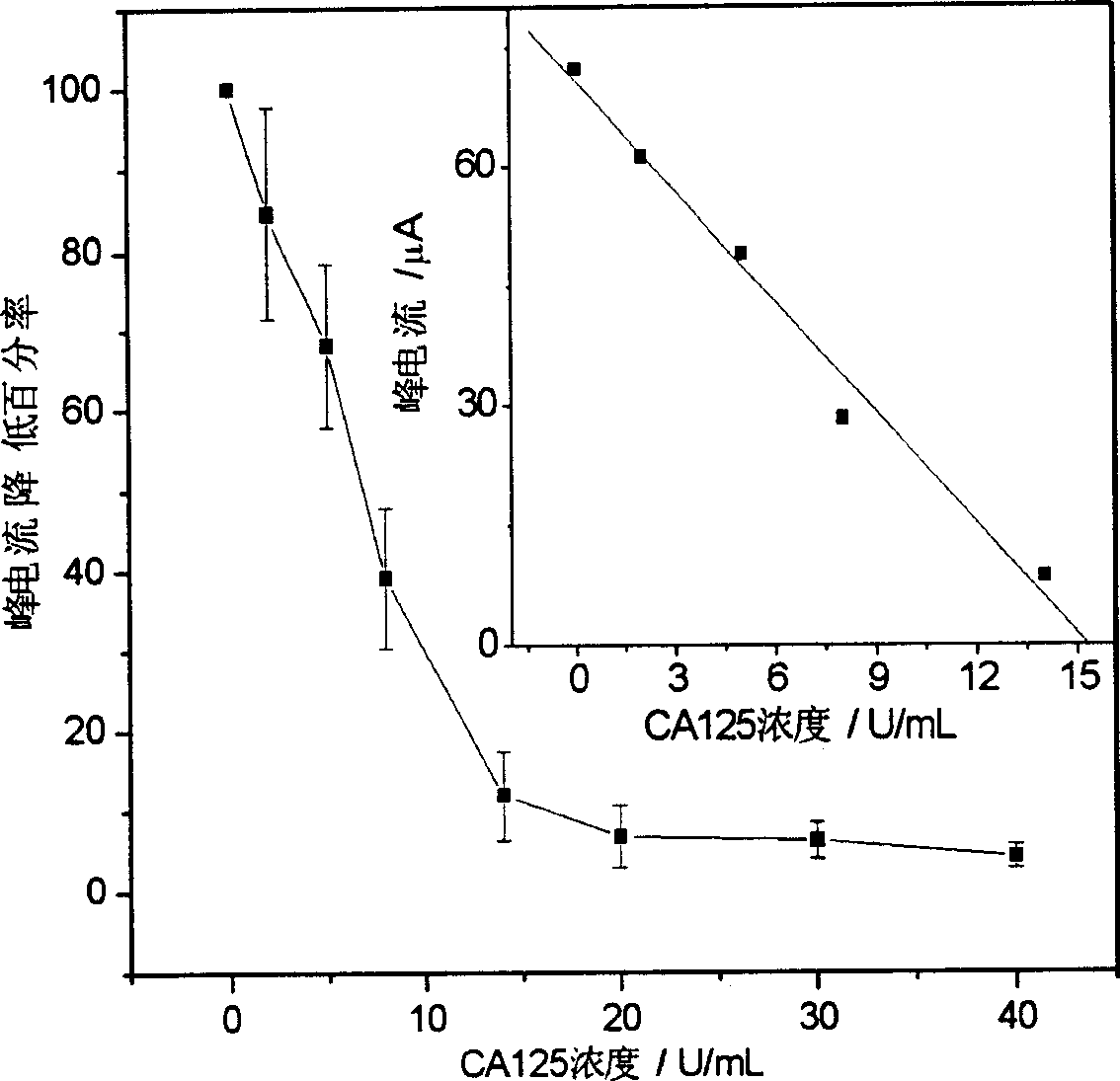

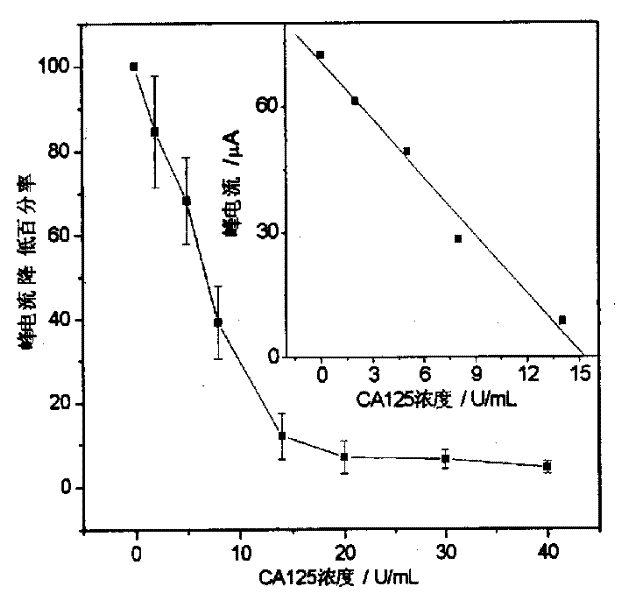

[0040] 2. Embodiment 2: Determination of CA125

[0041] (a) Optimization of measurement conditions: respectively change the incubation temperature, incubation time and the amount of HRP-labeled CA125 antibody in the reaction solution, and select the corresponding amount at the time of the maximum current response as the optimal measurement condition. The maximum current response was obtained by incubating at high temperature for 40 min. When the amount of HRP-labeled CA125 antibody in 50 microliters of the reaction solution was greater than 83%, the current response reached the maximum value.

[0042] (b) Determination of CA125: Under optimized experimental conditions, a series of standard CA125 antigen concentrations were measured by competitive immunoassay method to determine the standard curve for CA125 determination, and then the standard curve method was used to determine the concentration of CA125 antigen in the sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com