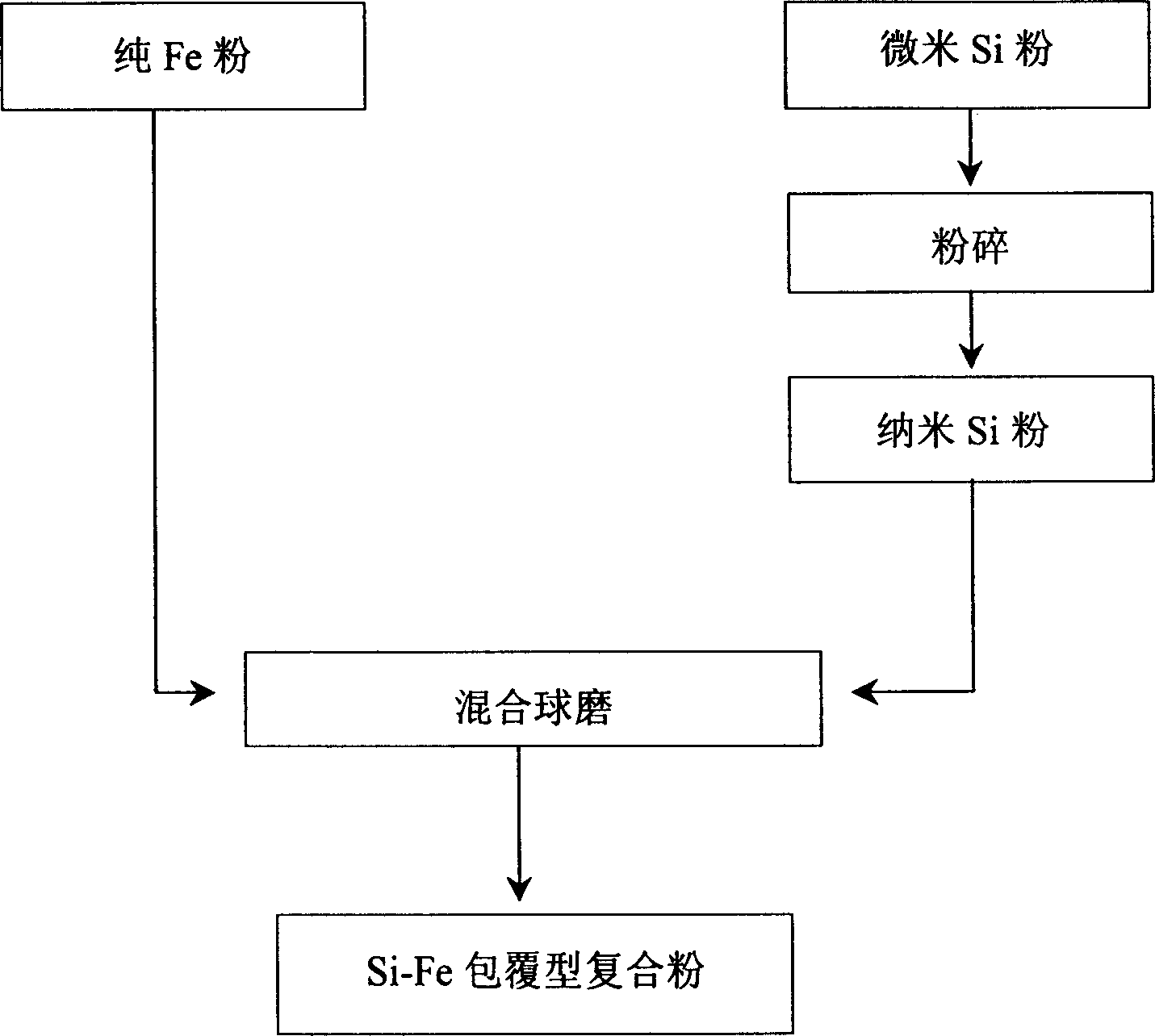

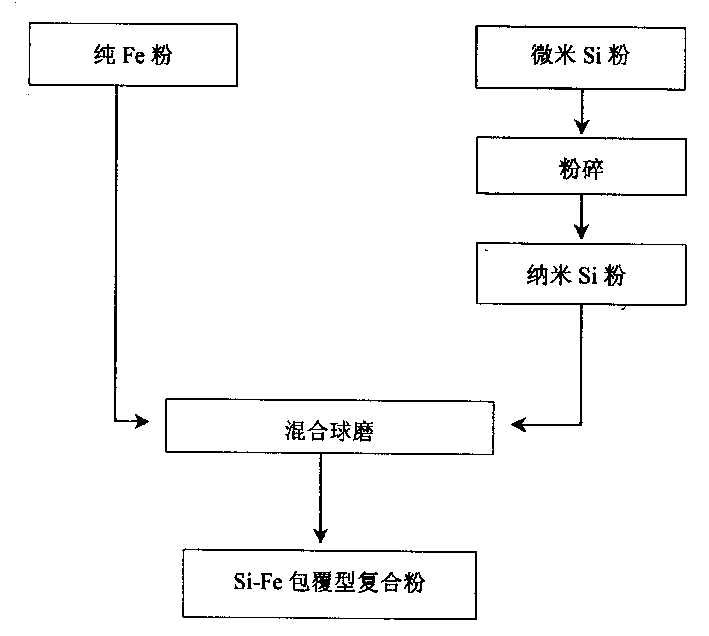

Method for preparing silicon-iron coating type composite powder

A coating type, composite powder technology, applied in coating and other directions, can solve the problems of high preparation cost, unsuitable for large-scale industrial production, unsuitable for Si-Fe composite powder, etc., and achieves simple process and easy mass production. , the effect of uniform distribution of Si

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Mix Si powder with an average particle size of 1 μm and a purity of 99.99% with an appropriate amount of absolute ethanol, place it in a high-energy ball mill made of stainless steel, and mill it for 30 hours; the ball-to-material ratio is 10:1, and the speed of the ball mill is 350 rpm; airtight ball mill The tank is protected by argon to prevent oxidation during the ball milling process;

[0017] Get 6 grams of pulverized silicon powder and 94 grams of iron powder with an average particle size of 100 μm for mixed ball milling, the ball-to-material ratio is 4:1, the ball mill speed is 350 rpm, ball milled for 1 hour, and the powder after ball milling is made into a sample.

Embodiment 2

[0019] 10 grams of Si powder with an average particle size of 1 μm and a purity of 99.99% was mixed with an appropriate amount of absolute ethanol, placed in a high-energy ball mill made of stainless steel, and ball milled for 40 hours. The ball-to-material ratio is 20:1, and the rotational speed of the ball mill is 350 rpm. The airtight ball milling tank was protected by argon to prevent oxidation during the ball milling process.

[0020] Take 6.5 grams of pulverized silicon powder and 93.5 grams of iron powder with an average particle size of 100 μm for mixed ball milling, the ball-to-material ratio is 4:1, the speed of the ball mill is 350 rpm, and the ball mill is performed for 2 hours. The powder after ball milling was made into a sample, which was analyzed with an electron probe, and the results were as follows: figure 2 shown. The results show that Si is uniformly coated around Fe, and the Fe particles are not deformed. This proves that the obtained powder is Si-Fe ...

Embodiment 3

[0022] Mix Si powder with an average particle size of 1 μm and a purity of 99.99% with an appropriate amount of absolute ethanol, place it in a high-energy ball mill made of stainless steel, and mill it for 35 hours; the ball-to-material ratio is 15:1, and the speed of the ball mill is 350 rpm; The tank is protected by argon to prevent oxidation during the ball milling process;

[0023] Get 7 grams of pulverized silicon powder and 93 grams of iron powder with an average particle size of 100 μm for mixed ball milling, the ball-to-material ratio is 4:1, the ball mill speed is 350 rpm, ball milled for 1.5 hours, and the powder after ball milling is made into a sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com