Method of treating industrial waste water by actived sludge-micro-electrolytic process

A technology for activated sludge and industrial wastewater, which is applied in water/sludge/sewage treatment, water/sewage treatment, biological water/sewage treatment, etc. It can solve the problems of increasing treatment costs, slag production, and treatment difficulties, and achieves High removal rate and good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

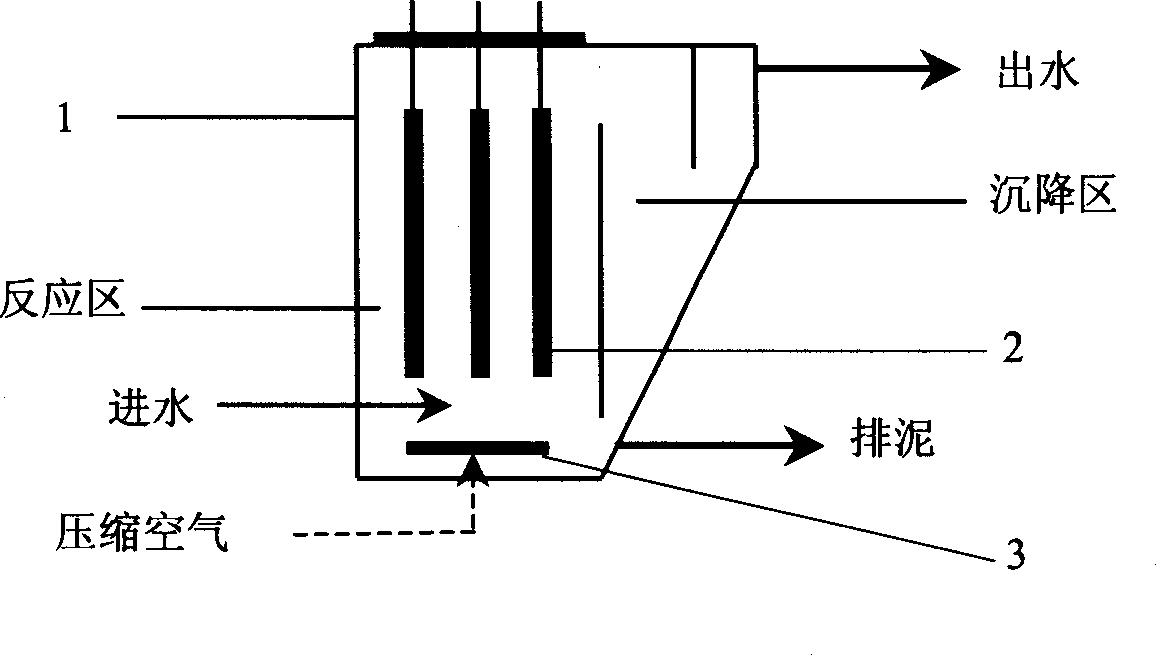

[0020] The activated sludge used in the test was taken from the first exposure tank of the south sewage treatment plant of Shengli Oil Refinery of Qilu Petrochemical Company. After being washed several times with tap water, it was poured into the tank. Hang a 25cm long 25×25 waste angle iron in the pool water. The treated wastewater is dry-process acrylic fiber process wastewater, and the COD after coagulation-sedimentation to remove insoluble COD is 1315.4mgL.

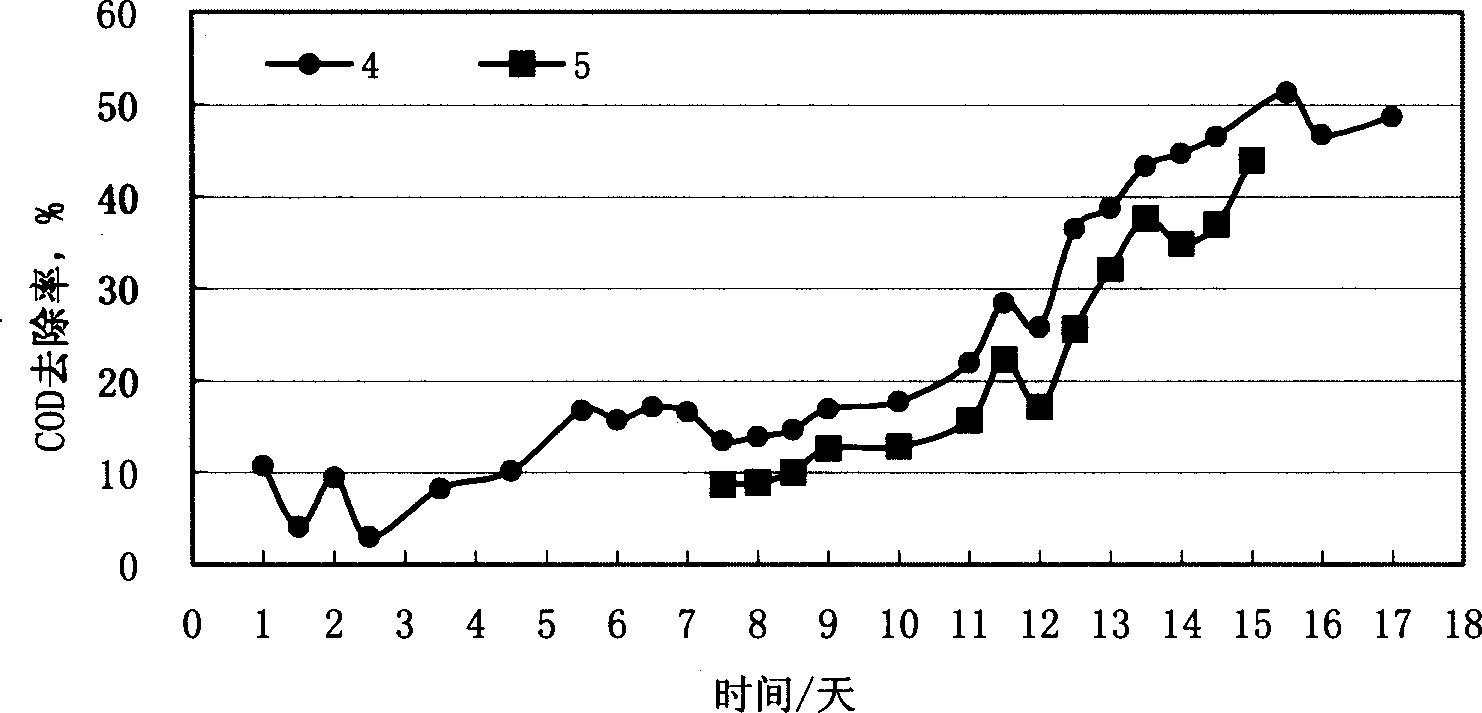

[0021] Control the temperature of the reaction zone to normal temperature, the pH value between 4.5 and 6.5, control the dissolved oxygen to be greater than 0.5mg / L, and the sludge concentration to be 2 to 4g / L. Gradually reduce the hydraulic retention time until the hydraulic retention time is controlled within 10 hours and the COD removal rate is 45%. At this time, the acclimatization of activated sludge is over.

[0022] The pH value is controlled at 6.0-6.5, the hydraulic retention time is 10 hours, the dissolved...

Embodiment 2

[0023] Example 2 According to the steps and conditions of Example 1, but the pH value of the reaction zone is controlled at 3.5-4.0, the hydraulic retention time is 10 hours, and the COD removal rate of wastewater is 48.5%.

Embodiment 3

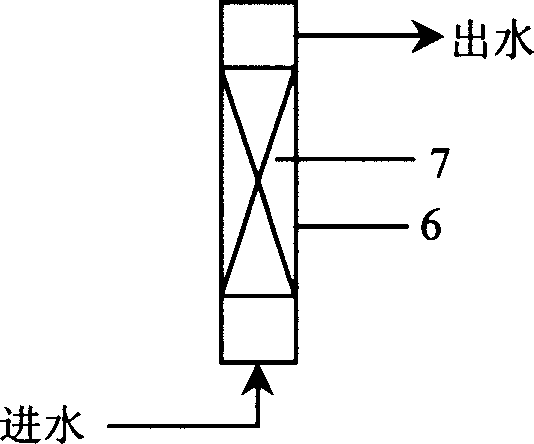

[0024] Example 3 According to the steps and conditions of Example 1, but using 20# carbon steel instead of angle steel to domesticate the activated sludge. After acclimatization, the pH value is controlled at 6.0-6.5, the hydraulic retention time is 10 hours, and the COD removal rate of wastewater is 51.3%. Comparative Example 1 The dry acrylic process wastewater in Example 1 was treated with iron filings filtration, and the influent COD was 1315.4 mg / L. device used see image 3 , the pH value of the influent was adjusted to 3. After 10 hours of passing through the water, COD begins to decrease, the lowest can be reduced to 995.3mg / L, and the COD removal rate is 24.3%, which is far lower than the COD removal rate of the method of the present invention. Moreover, the amount of slag produced is relatively large.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com