Compound dephosphorization agent with converter slag as raw material and preparing method thereof

A technology of compound dephosphorization agent and converter slag, applied in lime production and other directions, can solve the problems of complex processing of pre-melting dephosphorization agent, unstable performance of dephosphorization agent, long time for dephosphorization of slag, and reduce slag production. volume, shorten the processing time, and the effect of good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0033] A composite dephosphorization agent for molten iron pretreatment using converter slag as raw material, which is composed of the following raw materials and their weight percentages: 45-55% of converter slag, 3-5% of quartz sand, 22-34% of rolled steel skin, and 3% of bauxite ~6%, soda 10~14%, fluorite 0~5%. Raw materials that meet the composition requirements are crushed and mixed uniformly according to the above ratio, and after ball milling, sieving, pelletizing and drying, they are made into finished products with a diameter of 20-50mm. During the pretreatment of molten iron, the total amount of compound dephosphorization agent added is 15-25Kg per ton of steel. When in use, put it into the scrap steel trough, and add it together with the scrap steel at one time. Then, according to the conditions in the furnace, lime and slag-reducing agents are added in time to control the final composition of the slag within the target range. Converter slag is metallurgical slag ...

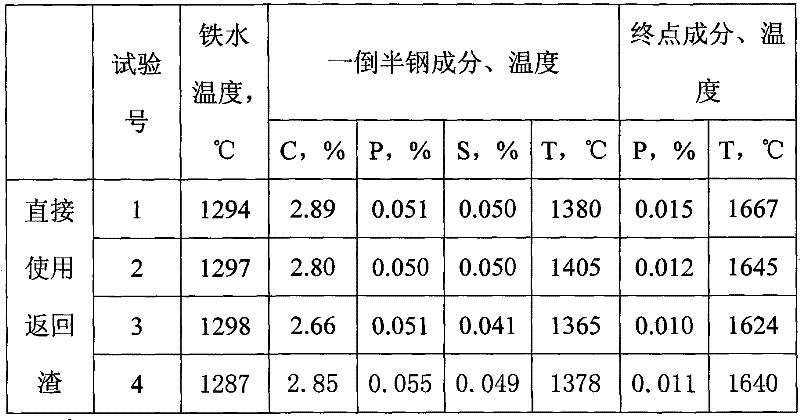

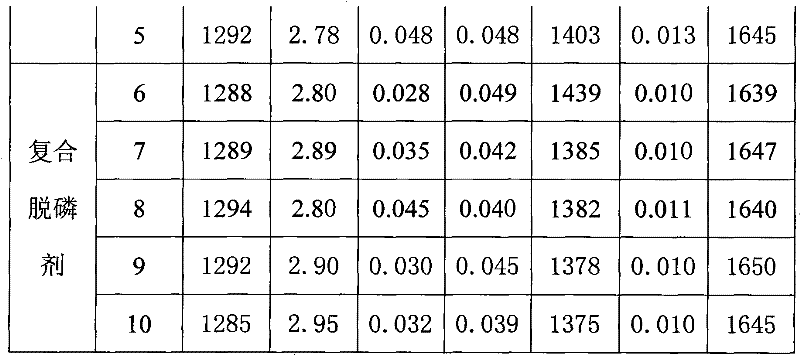

Embodiment 1

[0043] In this embodiment, the composition and weight percentage of the composite dephosphorization agent are: 54% converter slag, 24% rolled steel sheet, 3% quartz sand, 6% bauxite, and 13% soda. Since a certain amount of soda contained in this embodiment can improve the fluidity of slag, based on the purpose of environmental protection and reducing lining erosion, no fluorite is added in this embodiment. After the finished product is made according to the aforementioned method, according to the actual measurement results, the binary alkalinity of the dephosphorization agent is about 1.85, and the hemispherical point temperature is 1241°C, which meets the temperature requirements of molten iron under normal circumstances. The test adopts the double slag method, that is, the low-temperature dephosphorization operation is carried out first, and part of the converter slag is poured out when pouring, and then the slagging agent is added for decarbonization blowing. This embodimen...

Embodiment 2

[0049] In this embodiment, the composition and weight percentage of the composite dephosphorization agent are: converter slag: 50%, rolled steel sheet 26%, quartz sand 3%, bauxite 4%, soda 12%, fluorite 5%. After the finished product is made according to the aforementioned method, the binary alkalinity of the dephosphorization agent is about 1.8 and the temperature of the hemispheric point is 1235° C., which meets the temperature requirements of molten iron under normal conditions. Under the simulated dephosphorization condition of 1350℃, the slag is in good condition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com