A method for recovering waste salt in saline wastewater in the production of tebuconazole

A technology of salty wastewater and recovery method, applied in chemical instruments and methods, neutralized water/sewage treatment, alkali metal sulfite/sulfate purification, etc. Potassium recovery rate is not ideal and other problems, to achieve the effect of improving the removal rate and reducing the amount of slag produced by iron sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

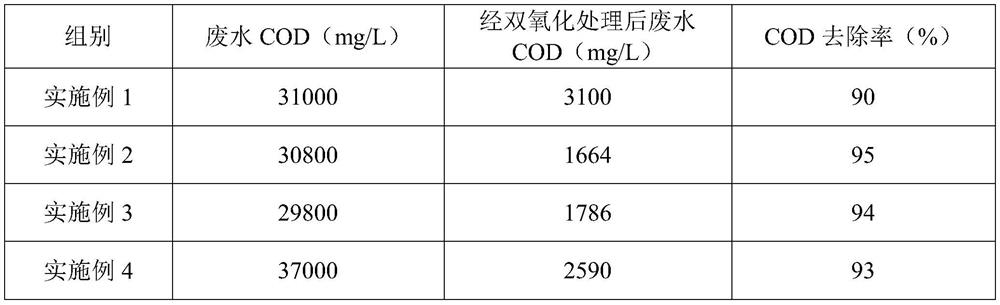

Embodiment 1

[0035] In this embodiment, the waste salt in the saline wastewater in the production of tebuconazole is recovered, including the following steps:

[0036] Step 1: using a sulfuric acid solution with a mass concentration of 98% to adjust the pH value of the saline wastewater in the production of tebuconazole to 3;

[0037] Wherein, the dosage of described sulfuric acid solution is to add 100g per ton of waste water:

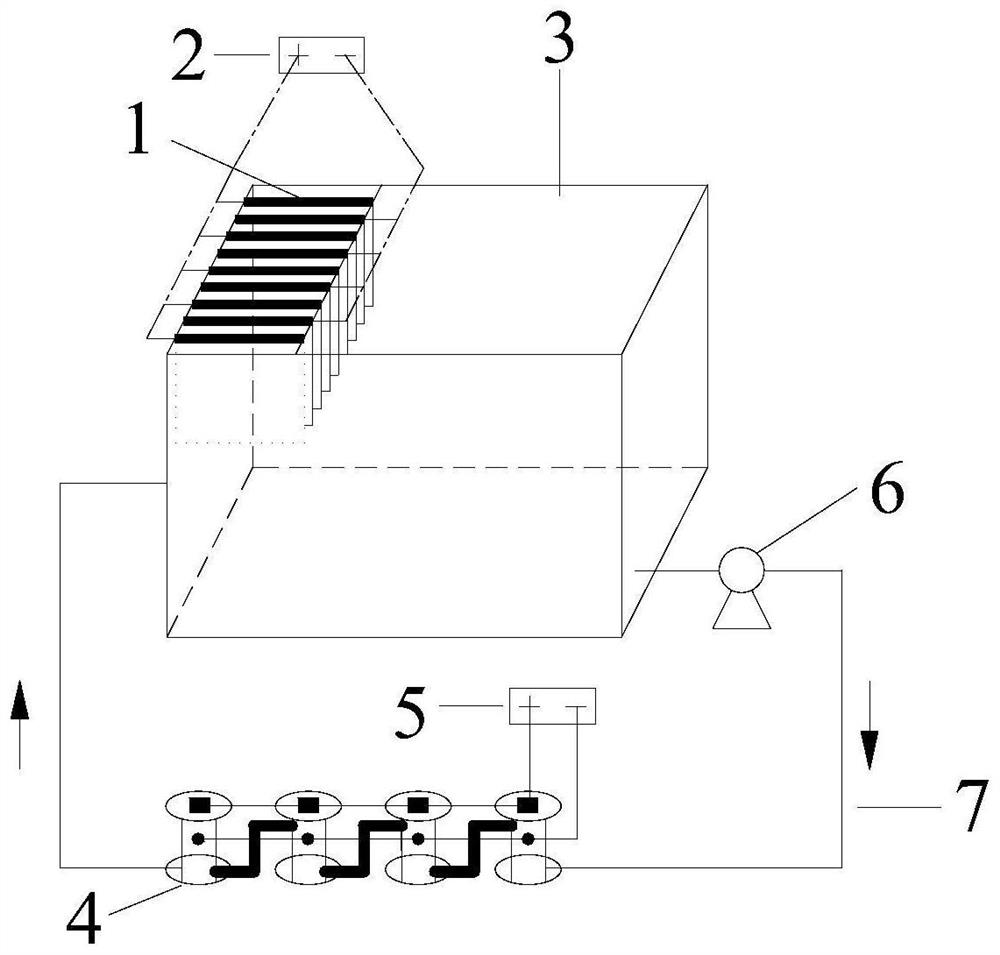

[0038] Step 2: Pass the waste water after pH adjustment into such as figure 1 In the shown double oxidation reactor coupled with electrocatalytic Fenton oxidation and electrochemical oxidation, the electrocatalytic Fenton oxidation current is set to 1A, the operating voltage is 2V, the operating temperature is 20°C, and the operating voltage of the electrochemical oxidation reaction is 3V , the current is 1A, the operating temperature is 20°C, the circulation pump is turned on for 24 hours, and a certain amount of H with a mass concentration of 30% is added durin...

Embodiment 2

[0043] In this embodiment, the waste salt in the saline wastewater in the production of tebuconazole is recovered, including the following steps:

[0044] Step 1: using a sulfuric acid solution with a mass concentration of 98% to adjust the pH value of the saline wastewater in the production of tebuconazole to 3.5;

[0045] Wherein, the dosage of described sulfuric acid solution is to add 90g per ton of waste water:

[0046] Step 2: Pass the waste water after pH adjustment into such as figure 1 In the shown double oxidation reactor coupled with electrocatalytic Fenton oxidation and electrochemical oxidation, the electrocatalytic Fenton oxidation current is set to 1.2A, the operating voltage is 2.5V, and the operating temperature is 25°C. The operating voltage of the electrochemical oxidation reaction is The current is 3.5V, the current is 1.1A, the operating temperature is 25°C, and the circulation pump is turned on to react for 24 hours. During the reaction, a certain amount...

Embodiment 3

[0051] In this embodiment, the waste salt in the saline wastewater in the production of tebuconazole is recovered, including the following steps:

[0052] Step 1: using a sulfuric acid solution with a mass concentration of 98% to adjust the pH value of the saline wastewater in the production of tebuconazole to 3.8; wherein, the dosage of the sulfuric acid solution is 88g per ton of wastewater:

[0053] Step 2: Pass the waste water after pH adjustment into such as figure 1 In the shown double oxidation reactor coupled with electrocatalytic Fenton oxidation and electrochemical oxidation, the electrocatalytic Fenton oxidation current is set to 1.5A, the operating voltage is 2.8V, and the operating temperature is 30°C. The operating voltage of the electrochemical oxidation reaction is The current is 3.8V, the current is 1.2A, the operating temperature is 30°C, the circulation pump is turned on for 24 hours, and a certain amount of H with a mass concentration of 30% is added during...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com